KTR Kupplungstechnik

GmbH

D-48407 Rheine

BoWex-ELASTIC®

Operating-/Assembly Instructions

Design 065 (HEW1 and HEW2)

KTR-N

sheet:

edition:

40114 E

7

4

Gezeichnet: 08.04.04 Sha/Hk Ersatz für: KTR-N vom 01.12.99Schutzvermerk

ISO 16016 beachten. Geprüft: 08.04.04 Sha Ersetzt durch:

4 Assembly

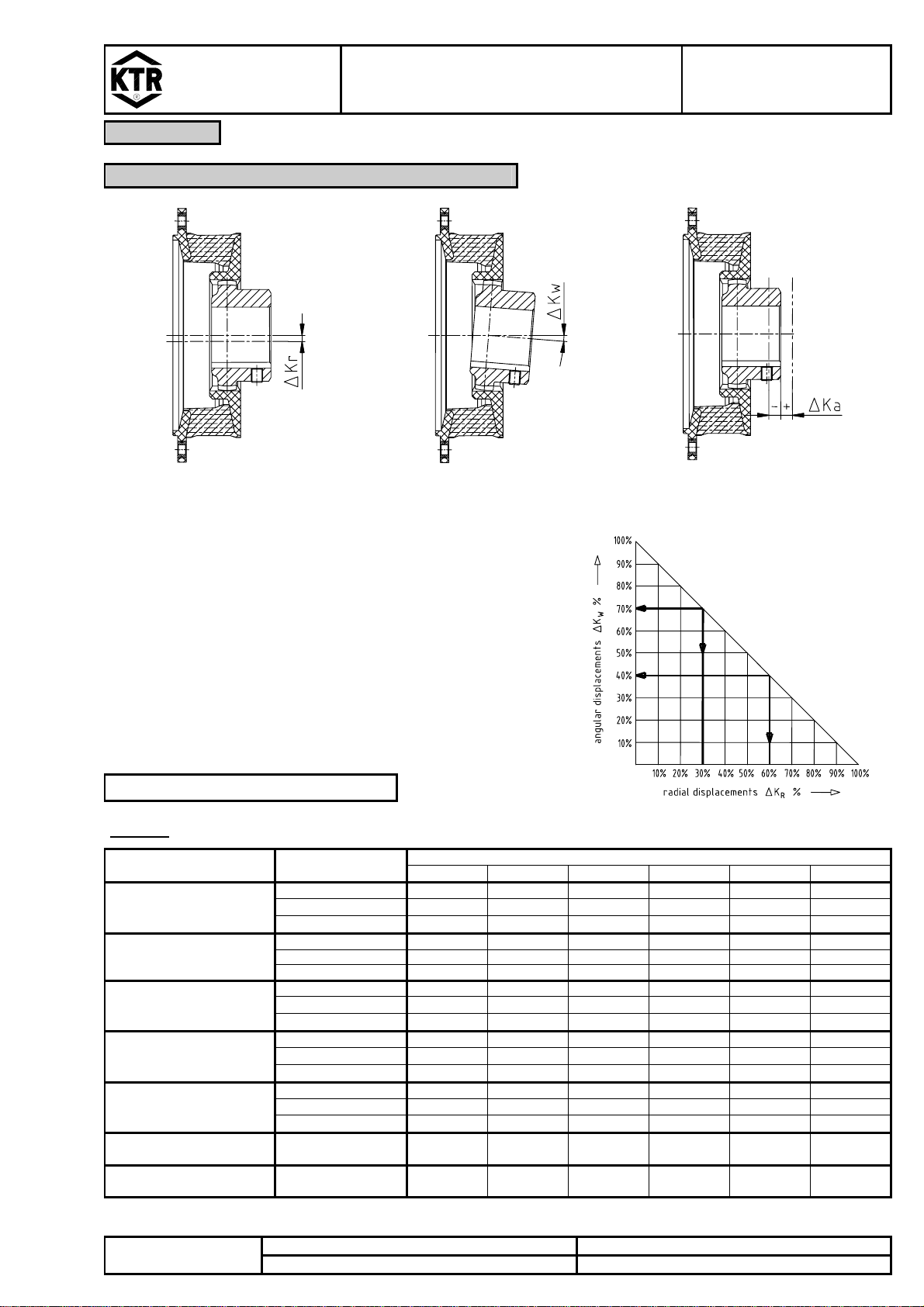

4.4 Displacements - Alignment of the Couplings

radial displacements angular displacements axial displacements

picture 6: displacements

Example for the misalignment

combinations given in picture 7:

Example 1:

∆KR= 30%

∆KW= 70%

Example 2:

∆KR= 60%

∆KW= 40%

∆Ktotal = ∆KR+ ∆KW≤100 %

picture 7: combinations

of displacement

Table 5:

BoWex-ELASTIC®HEW size

displacements elastomer-hardness

[Shore A] W 42 HE 42 HE 48 HE 65 HE 80 HE G 80 HE

40 1,0 1,1 1,2 1,6 1,8 2,0

50 - 1,0 1,1 1,5 1,7 1,9

perm. radial displacement

with n=1500 1/min.

∆Kr (mm) 65 - 0,5 0,5 0,7 0,8 0,9

40 0,7 0,8 1,1 1,4 1,6 1,8

50 - 0,7 1,0 1,3 1,5 1,7

perm. radial displacement

with n=3000 1/min.

∆Kr (mm) 65 - 0,4 0,4 0,5 0,6 0,8

40 3,2 3,6 3,8 5,1 5,7 6,0

50 - 3,3 3,5 4,7 5,3 5,7

max. radial displacement

∆Krmax. (mm) 1) 65 - 1,5 1,7 2,2 2,4 2,7

40 1,0 1,0 1,0 1,0 1,0 1,0

50 - 0,75 0,75 0,75 0,75 0,75

perm. angular displacement

with n=1500 1/min.

∆Kw (°) 65 - 0,5 0,5 0,5 0,5 0,5

40 0,5 0,5 0,5 0,5 0,5 0,5

50 - 0,4 0,4 0,4 0,4 0,4

perm. angular displacement

with n=3000 1/min.

∆Kw (°) 65 - 0,25 0,25 0,25 0,25 0,25

max. angular displacement

∆Kwmax. (°) 1) 40 / 50 / 65 1,5 1,5 1,5 1,5 1,5 1,5

perm. axial displacement

∆Ka (mm) 40 / 50 / 65 ±2 ±2 ±2 ±2 ±2 ±3

1) for short-term start