KTR Kupplungstechnik

GmbH

D-48407 Rheine

POLY

Operating-/Assembly Instructions

Design PKD

KTR-N

sheet:

edition:

49612 E

2

5

Gezeichnet:

13.01.03 Sha/At Ersatz für: KTR-N v. 18.02.02 Verteiler

Urheberschutz

gemäß DIN 34

Geprüft: 14.01.03 Sha Ersetzt durch: W

KVVA

MKC

1 Technical Data

Bild 2: Poly -Elastomerpaket

NBR (Perbunan) 92 ShA

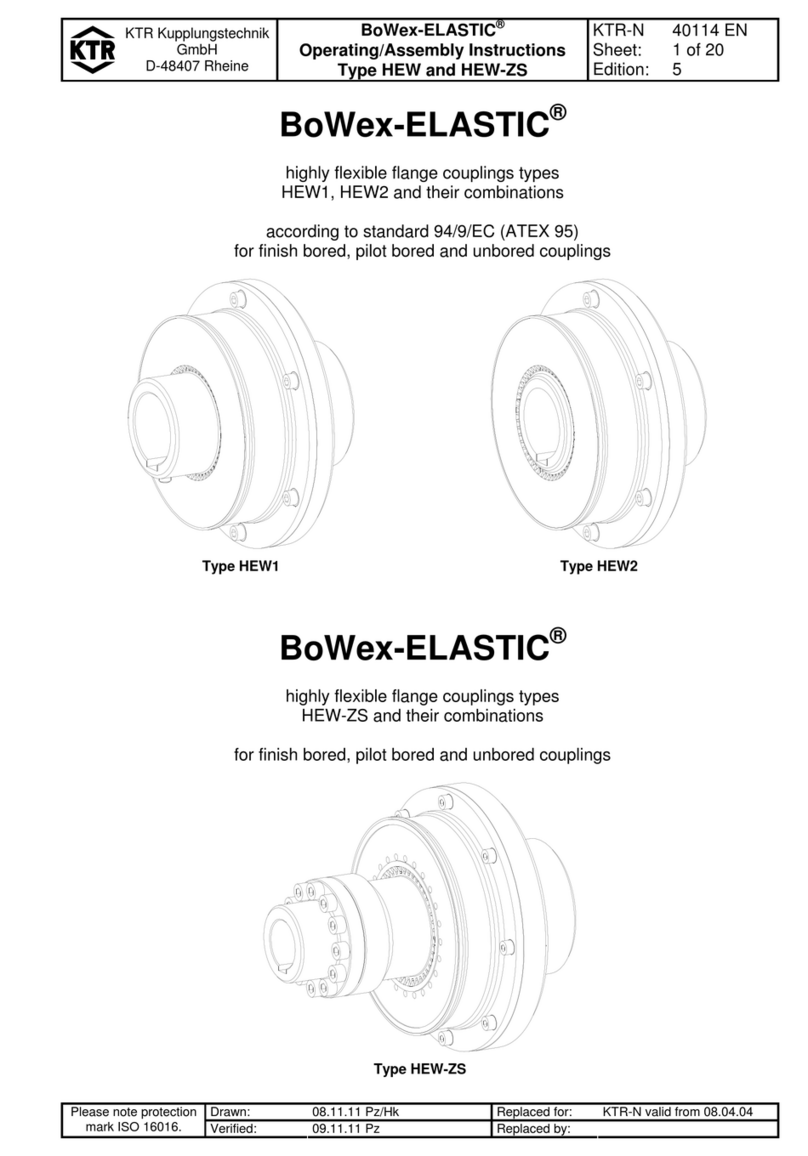

picture 1: POLY design PKD

Components:

1cam part (preferably to be

used at the driving end)

2D flange hub

3D cam ring

Table 1: dimensions design PKD

dimensions [mm]finish bore

dmax. [mm] general thread of setscrew

POLY

size pilot

bore compo-

nent 1 compo-

nent 2D DHDDDl1, l2MDNELPKD Gttightening torque

TA[Nm]

15 -50 45 157 90 75 65 35 21 4134 M8 15 10

17 -60 50 176 100 90 70 40 26 4144 M8 15 10

19 -75 65 195 125 107 75 45 27 4154 M8 15 10

20 -65 60 205 115 105 80 45 22 4164 M8 15 10

22 -85 75 224 140 129 90 59 38 4184 M10 20 17

25 -90 85 257 150 140 100 60 43 5205 M12 20 40

28 -100 95 288 165 160 110 65 44 5225 M12 20 40

30 -110 100 308 180 170 130 75 58 5265 M16 20 80

35 60 130 130 373 210 210 160 95 70 5325 M16 25 80

40 70 145 145 423 240 240 180 115 85 5365 M16 25 80

45 80 160 160 473 270 270 180 110 74 6366 M16 30 80

50 90 170 170 543 290 290 200 130 80 6406 M16 30 80

55 100 180 180 580 310 310 200 120 74 8408 M16 30 80

60 110 200 190 630 350 330 230 135 85 8468 M16 30 80

65 120 210 200 685 360 340 250 150 90 10 510 M16 30 80

Table 2: dimensions elastomer packages

coupling size 15 17 19 20 22 25 28 30 35 40 45 50 55 60 65

quantity of packages 1) 12 12 12 12 16 16 16 16 20 20 20 20 20 20 20

package size 33a 43b 45678910 11 12 13

h24,6 26,8 34,6 29,6 34,6 40,6 42,4 45,1 52,6 58,1 70,1 75,5 91,4 103

b27,2 27,7 34,9 29,6 34,9 40,0 43,7 60 59,9 69 79 81 98,2 108,1

dimensions

[mm] t16,1 18,4 19,6 18,4 19,6 22,2 23,7 22,3 29,6 29,3 36,3 42,5 44,3 48,5

1) Quantity for the complete coupling.