The GEARex®all-steel gear coupling is a flexible shaft connection. It is able to compensate for shaft

misalignment, for example caused by manufacturing inaccuracies, thermal expansion, etc.

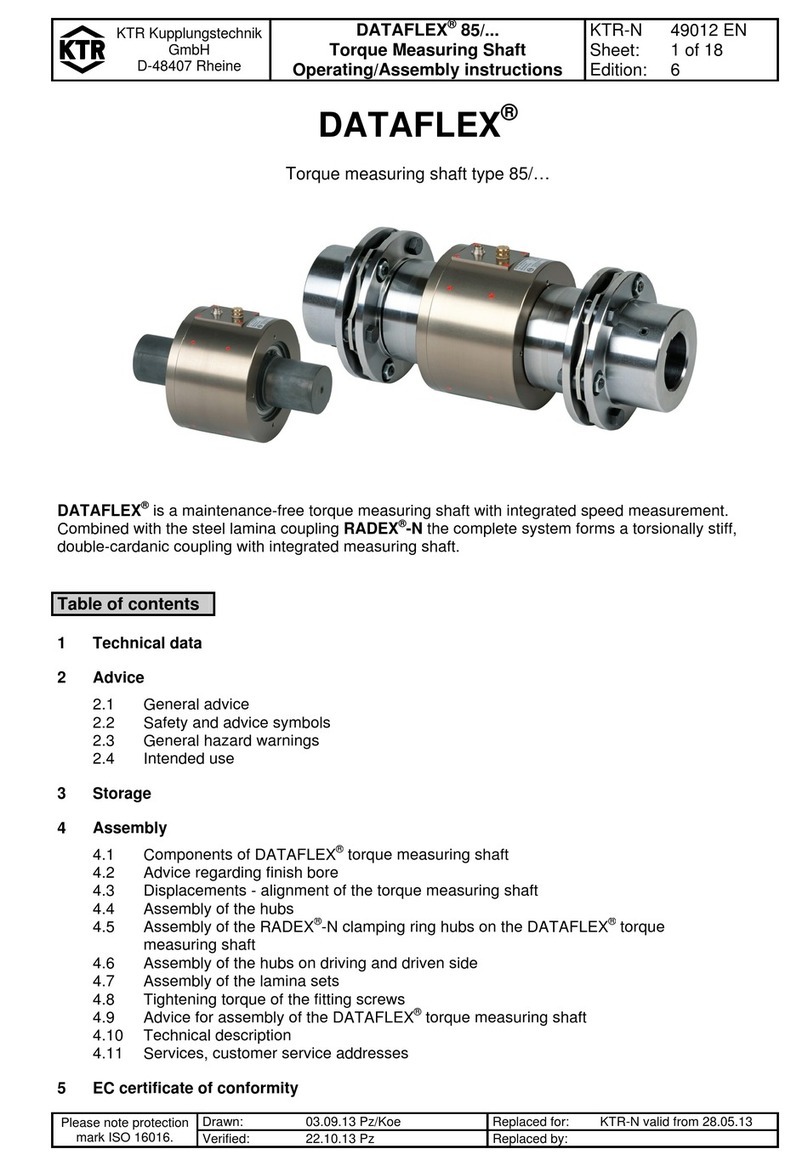

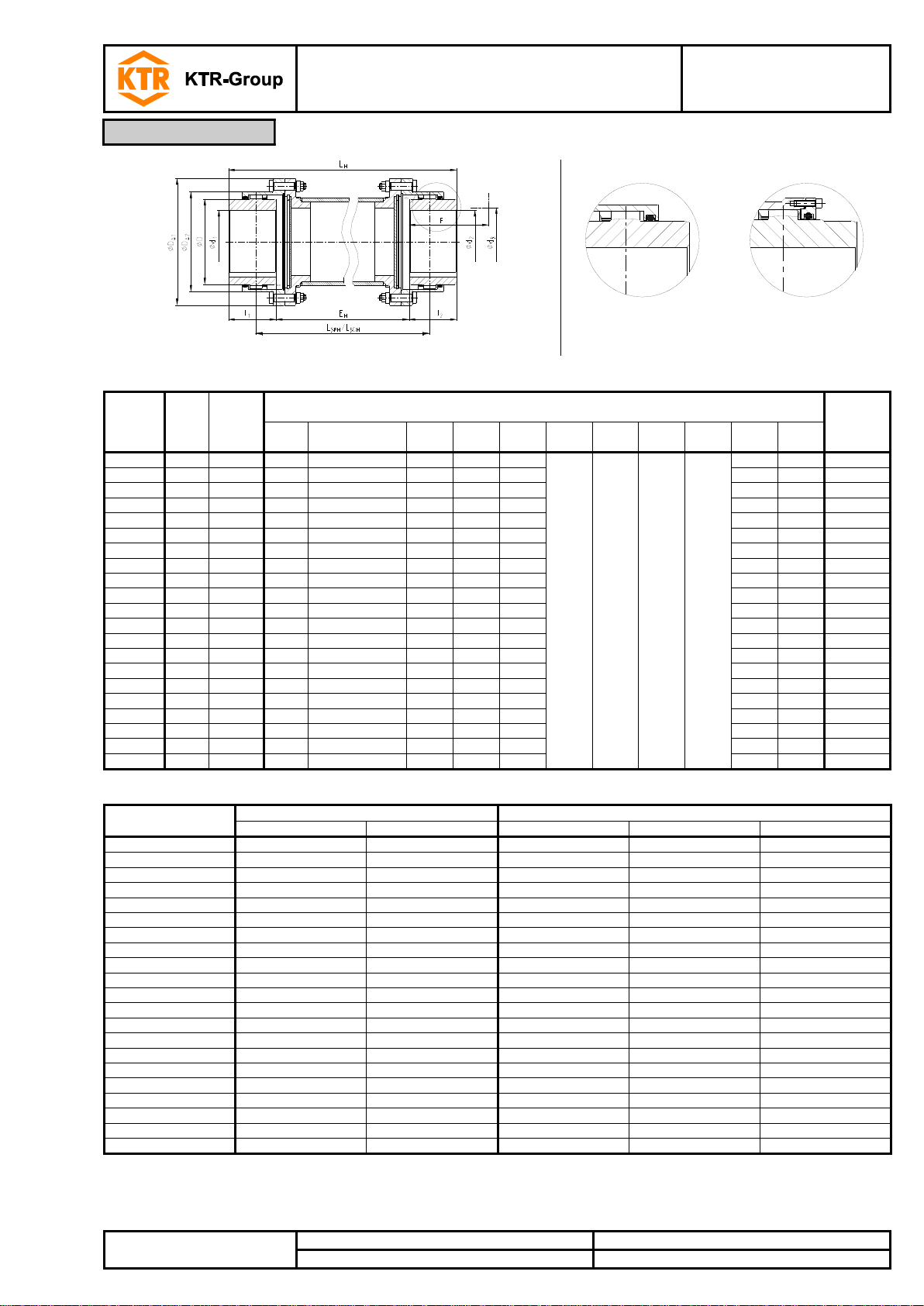

1Technical data 4

2Advice 8

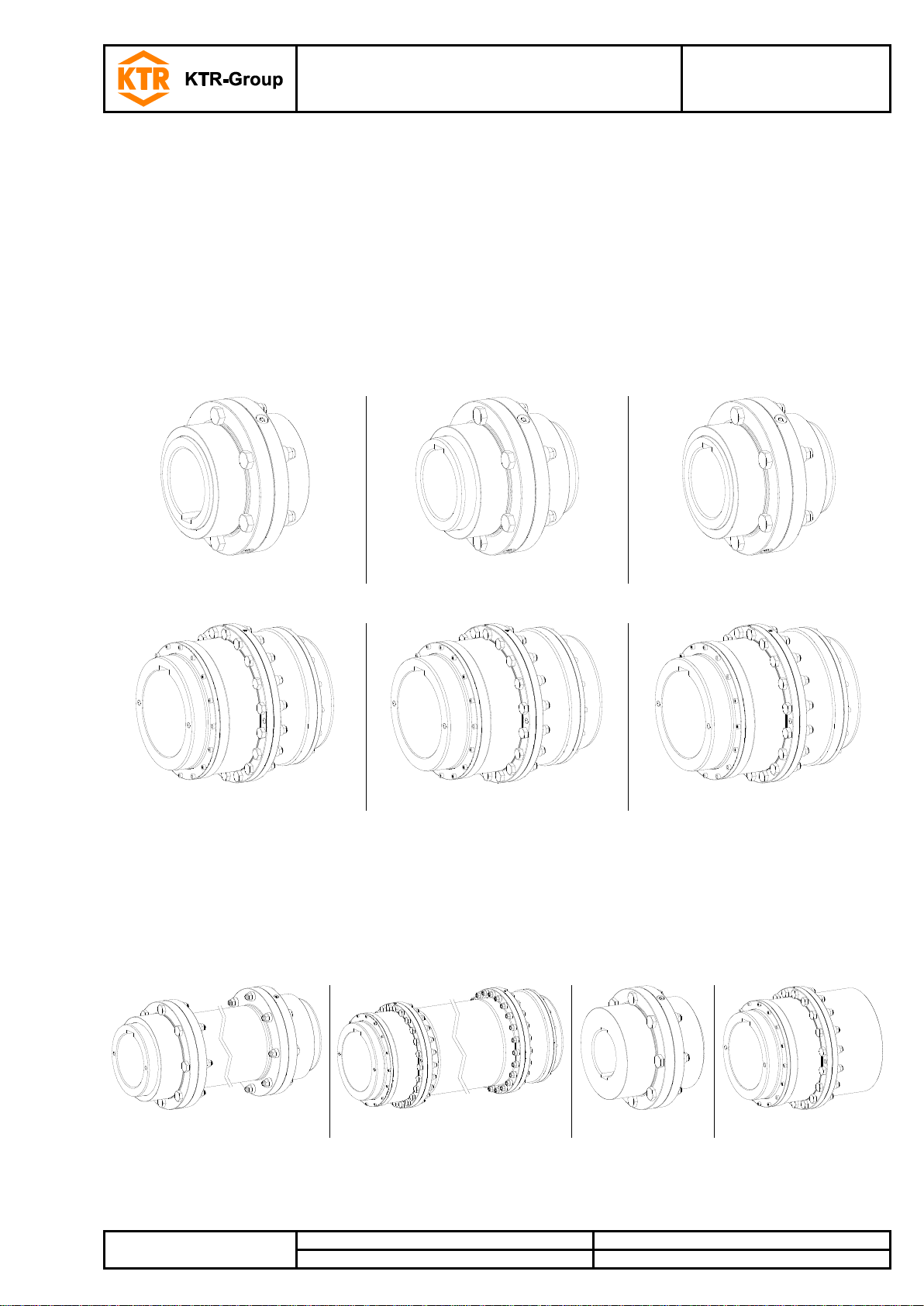

2.1 General advice 8

2.2 Safety and advice symbols 8

2.3 General hazard warnings 8

2.4 Intended use 9

2.5 Coupling selection 9

2.6 Reference to EC Machinery Directive 2006/42/EC 9

3Storage, transport and packaging 10

3.1 Storage of the coupling 10

3.2 Storage of O-rings 10

3.3 Transport and packaging 10

4Assembly 10

4.1 Components of the couplings 11

4.2 Advice for finish bore 15

4.3 Assembly of the coupling (general) 16

4.4 Assembly of the types FA, FB, FAB, FH and FR 17

4.5 Assembly of types DA, DB, DAB, DH and DR 18

4.6 Displacements - alignment of the couplings 20

5Start-up and lubrication 21

5.1 Start-up of the coupling 21

5.2 Types of grease recommended 22

5.3 Grease feeding 23

5.4 Grease capacity 23

6Breakdowns, causes and elimination 24

7Maintenance and service 27

7.1 Intervals of maintenance 27

7.2 Replacement of grease 27

7.3 Replacement of sealing elements 28

7.4 Standard values for circumferential backlash 29

7.5 Standard values of wear 30

7.6 Cleaning of the coupling 31

7.7 Replacement of coupling 31

7.8 Disassembly of the coupling 31

8Disposal 32

9Spares inventory, customer service addresses 32