KTR Kupplungstechnik

GmbH

D-48407 Rheine

DATAFLEX

85/...

Torque Measuring Shaft

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

49012 EN

2 of 18

6

Please note protection

mark ISO 16016. Drawn: 03.09.13 Pz/Koe Replaced for: KTR-N valid from 28.05.13

Verified: 22.10.13 Pz Replaced by:

1 Technical data

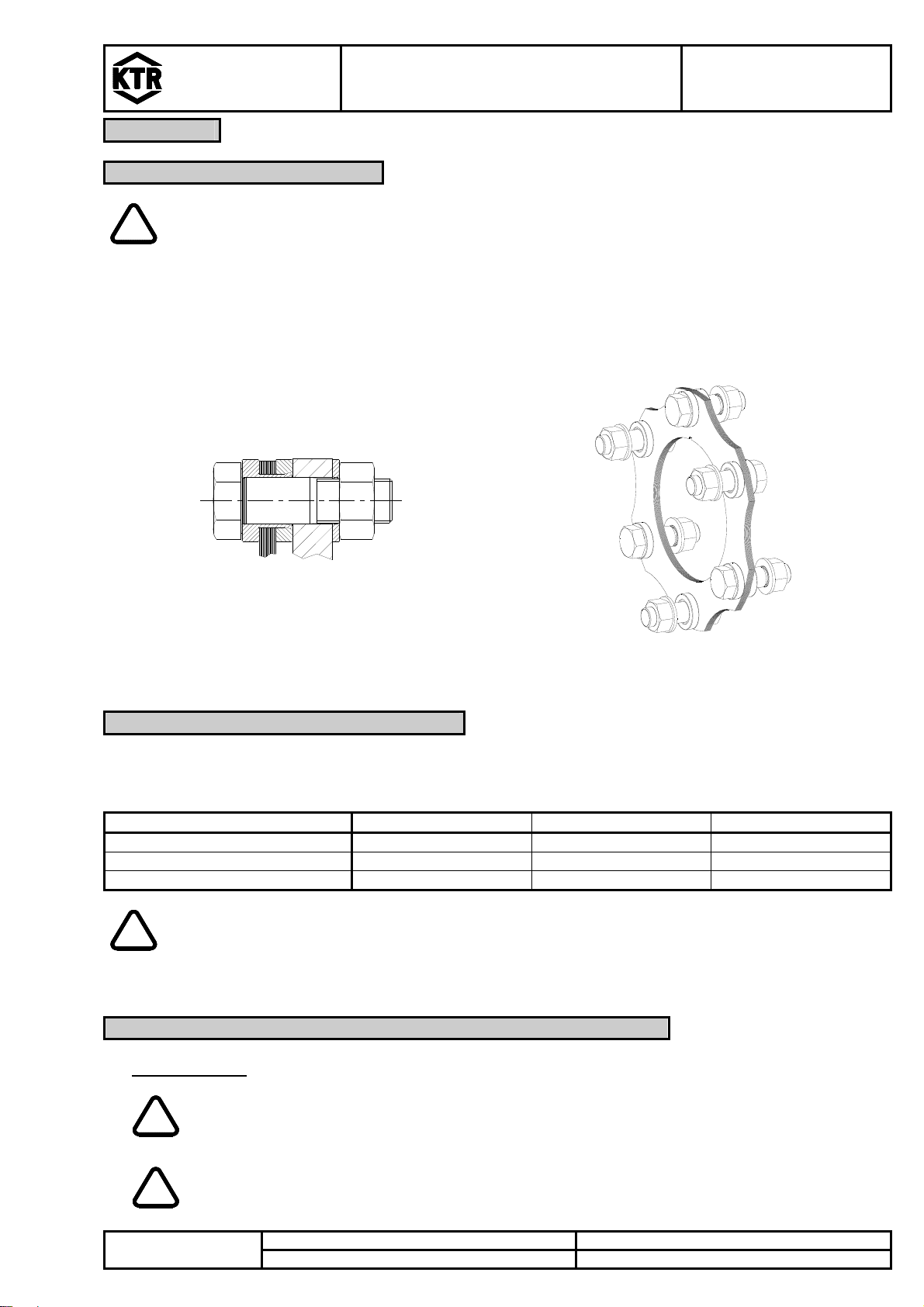

DATAFLEX®torque measuring shaft

Illustration 1: DATAFLEX®torque measuring shaft

Table 1: Dimensions

DATAFLEX

type Dimensions [mm]

d D L1L

2L

3L

4L

5

85/2000 85 215 344 90 164 153 10

85/5000

85/10000

Table 2: Technical data

Coupling size DATAFLEX

85/2000 85/5000 85/10000

Electrical data

Nominal torque TKN [Nm] -2000 .. +2000 Nm -5000 .. +5000 Nm -10000 .. +10000 Nm

Band width of torque signal [kHz] (-3dB) 16

Error in linearity incl. hysteresis [%]

< ±0,5

Influence of temperature [%/10K] 0,5

Nominal temperature range [°C] 0 - 55

Supply voltage [V] DC 24 ± 4

Max. current consumption [mA] 100

Torque output

Output voltage torque [V] 0 ... 10

Output current torque [mA] 4 ... 20

Speed output

Number of impulses / revolution 60

Amplitude [V] 24/5V

DC speed output [V] 0 - 10

Scale of direct voltage output 16 settings via micro switch

Inaccuracy of DC output [%]

± 0,2

Direction signal [V] to be omitted

Mechanical data

Static load limit TKmax.

[%] 150

Breaking load TK break

[%] 300

Max. bending torque [Nm] 380 760 1270

Max. radial force [N] 1500 3000 5000

Max. axial force [kN] 50 80 110

Weight [kg] 22,6 23,3 23,9

Torsion spring stiffness CT[Nm/rad] 382000 818570 1273330

Torsion angle with TKN [degrees] 0,30 0,35 0,45

Mass moment of inertia [kgmm

] 16360 16790 17420

Max. speed [rpm] 2500

1) Referring to rated torque TKN

2) With connection housing DF2

3) Referring to measuring range value