® ®

01

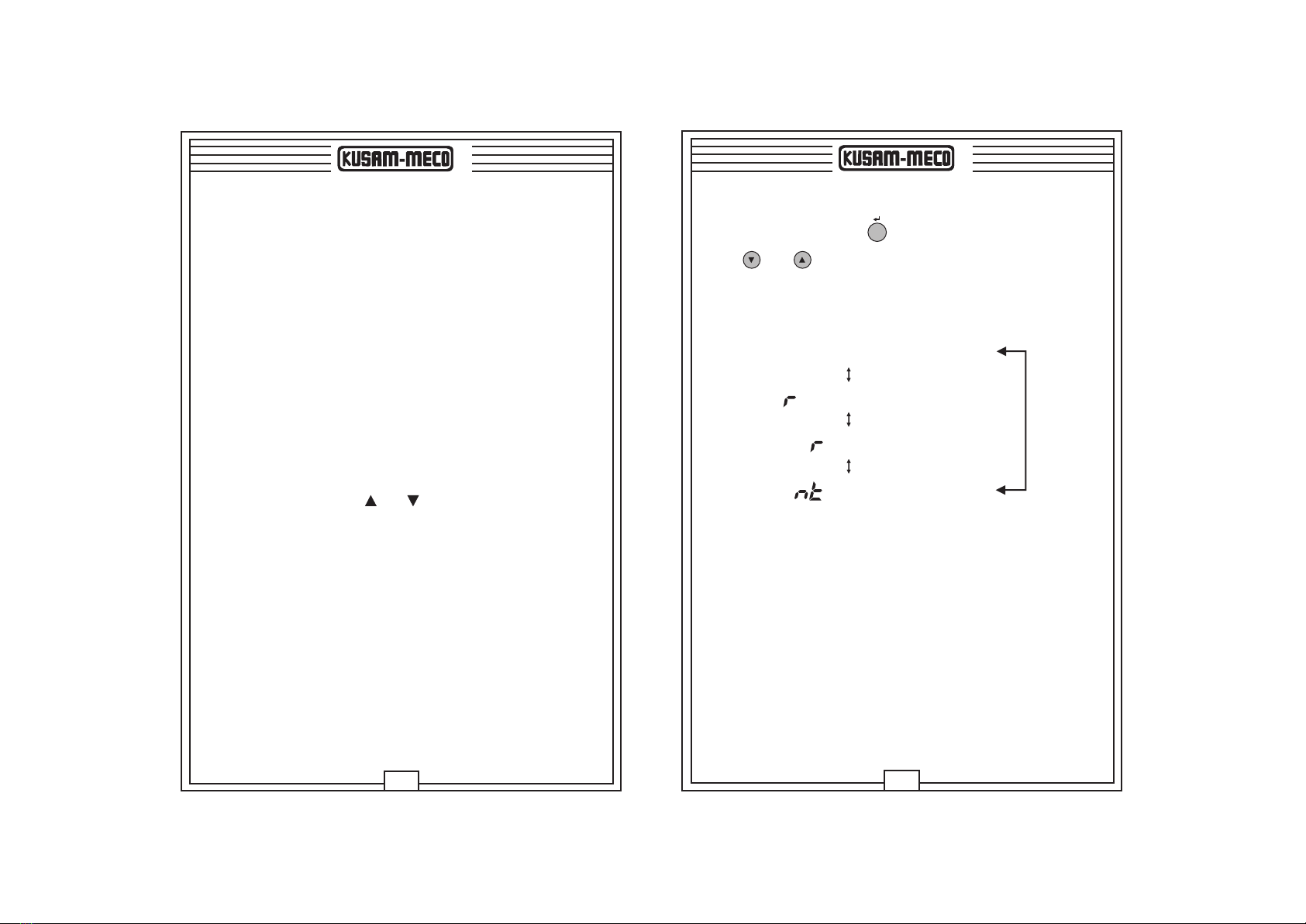

I. INTRODUCTION :

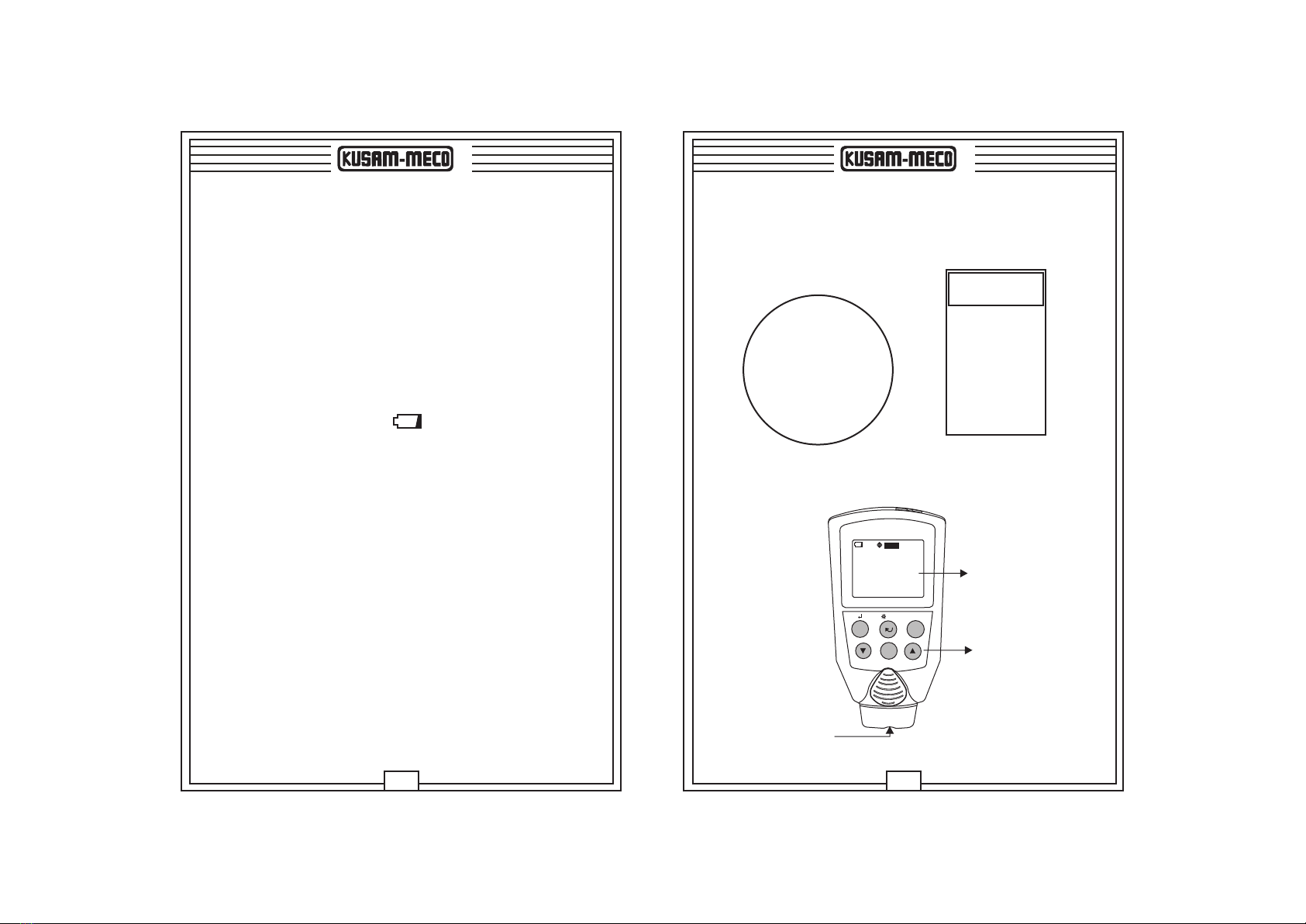

KM 117A is a ferrous coating thickness gauge designed for simply

one hand operation.

II. FEATURES :

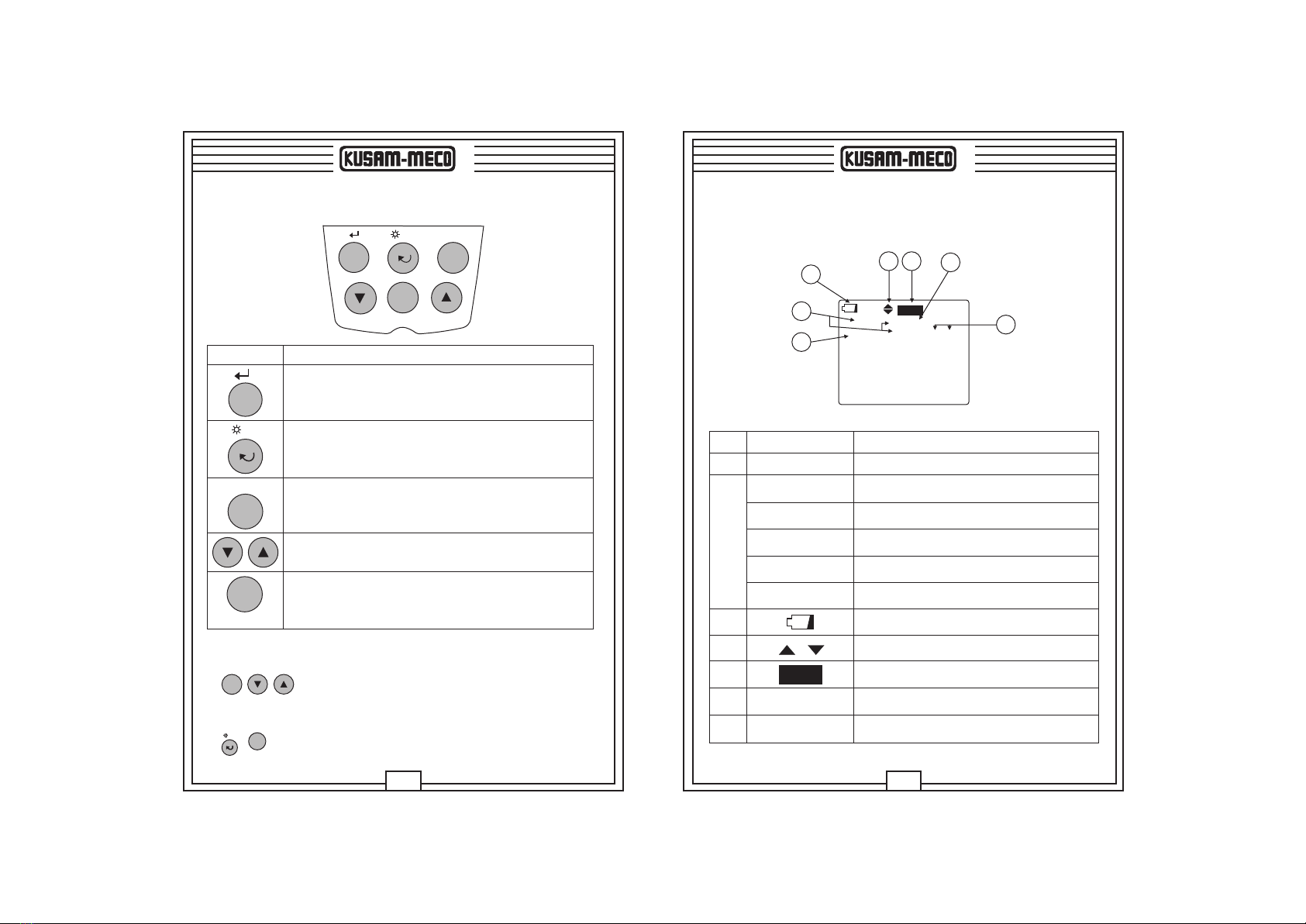

1. LED backlight.

2. LCD display reverse.

3. Auto power off.

4. Low-battery indicator.

5. Calibration for normal use.

6. Data logging function.

7. Warning beeper triggers by hi/lo limit settings.

8. Inch and Metric measurement options.

9. Zeroing Plate and Standard Coating Plate.

10. Attached with carrying strap.

11. Soft carrying case.

III. SAFETY INFORMATION :

It is recommended that you read the safety and operation instructions

before using the coating thickness gauge.

1. CAUTION :

1. Do not use the unit near any device which

generates strong electromagnetic radiation

or near a static electrical charge, as these

may cause errors.

2. Do not use the unit where it may be

exposed to corrosive or explosive gases.

The unit may be damaged, or explosion

may occur.

02

3. Do not keep or use this unit in an environment where it will be

directly illuminated by sunshine, or where it condensation. If

you do, it may be deformed, its insulation may be damaged, or

it may no longer function according to specification.

4. Do not place the meter on or around hot objects (70°C/158°F).

It may cause damage to the case.

5. If the meter is exposed to significant changes in ambient

temperature, allow 30 minutes for temperature stabilization,

before taking measurement.

6. Condensation may form on the sensor when going from a cold

to hot environment. Wait for 10 minutes for condensation to

dissipate before taking measurements.

7. This unit is not constructed to be waterproof

and dustproof. Do not use it in a wet or very

dusty environment.

8. In order to take accurate measurement, make

sure the sensing tip contacts the coated

surface tightly without tilting.

9. Please make sure there is no air bubbles

between substrate and coating.

10.Substrate zeroing calibration must be implemented for

each use.

11. Two point calibration is suggested to implement for

frequent testing points to increase measuring accuracy.