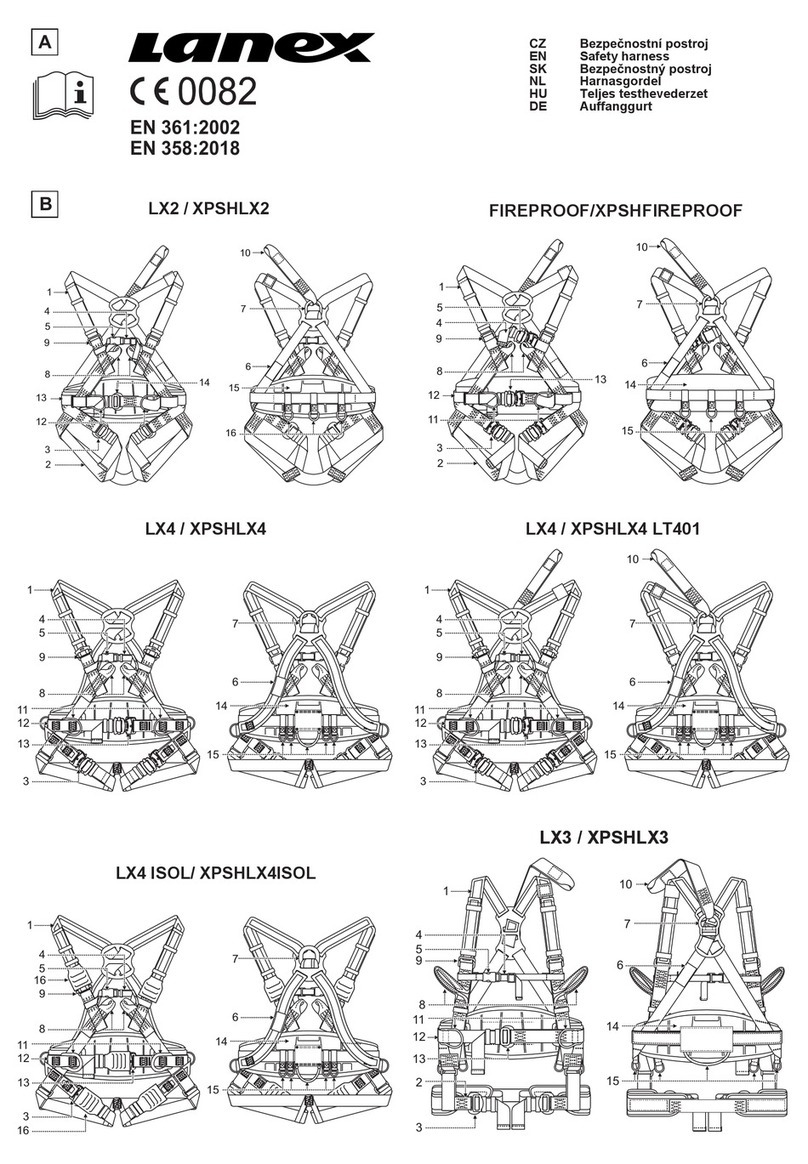

INSTRUCTION MANUAL

REF. NO: DX020

LANEX a.s., Hlučínská 1/96, 747 23 Bolatice, Tel.: +420 553 751 111, Fax: +420 553 654 125,

General information

The equipment should be used solely by persons trained in its use.

The equipment shall not be used by persons, whose condition of health may affect safety

during everyday or emergency use.

It is necessary to prepare an emergency action plan which will be ready for use in case of a

need.

Any modifications to the equipment without written permission from the manufacturer shall

be forbidden.

Any repairs of the equipment may only be done by the manufacturer of the equipment or its duly authorized

representative.

The equipment cannot be used for applications other than intended.

Prior to use make sure that all the components of the system work properly. Make periodical checks of

connections and fit of the components of the equipment to avoid accidental loosening or disconnection.

Never use any set in which the operation of any component is disturbed by another.

All components of the equipment should meet the requirements of respective regulations and instructions for

use of the equipment, as well as all effective standards.

Prior to every use the equipment should be carefully visually inspected to check its condition and proper

operation. The visual inspection shall be done by the user of the equipment.

During the visual inspection it is necessary to check all components of the equipment, with particular focus

on any damage, excessive wear, corrosion, abrasion, cuts or incorrect operation. Particular attention should

be paid to:

- buckles, adjusting elements, attaching points (buckles), webbings, seams, loops, connectors.

At least once a year, after every 12 months of use, the protective equipment should be withdrawn from use

to carry out detailed periodical inspection. The periodical inspection may be carried out by the person who is

responsible in the facility for periodical inspections of the protective equipment and trained accordingly.

Periodical inspections can also be carried out by the manufacturer of the equipment or by a company

authorized by the manufacturer. It is necessary to carefully check all components of the equipment, paying

particular attention to any damage, excessive wear, corrosion, abrasion, cuts or incorrect operation (see the

previous point). In certain cases, where the equipment has a complex structure, the periodical inspections

can only be carried out by the manufacturer of the equipment or by its authorized representative. Upon

completion of the periodical inspection the date of the next inspection shall be determined.

Regular periodical inspections are essential in terms of the condition of equipment and safety of the user,

which depends on full efficiency and durability of the equipment.

During the periodical inspection it is necessary to check legibility of all protective equipment marking

(feature of the given piece of equipment).

All information about the equipment (type, serial number, date of purchase and commissioning, name of the

user, information about repairs and inspections and withdrawal from use) must be entered into the given

equipment identity card. Entries in the identity card are the responsibility of the work facility in which the

equipment is used. The card is filled in by the person who is responsible for protective equipment in the

facility. Use of the equipment without a filled in identity card is forbidden.

Where the equipment is sold beyond the territory of the country of its origin the supplier of the equipment

shall provide it with instructions for use, instructions for maintenance and information about the periodical

inspections and repairs in the language of the country where it will be used. The equipment shall be

immediately withdrawn from use when any doubts arise as to the condition of the equipment or its proper

performance. The equipment shall be released for use again only after a detailed inspection by the

manufacturer of the equipment and its written consent to reuse the equipment.

During the use of the equipment particular attention should be paid to dangerous phenomena affecting the

performance of equipment and the user's safety, with particular focus on:

-lanyard looping or trailing over sharp edges;

-pendulum falls;

-electrical conductivity;

-any damage such as cuts, abrasion, corrosion;

-extreme temperature impact;

-climatic exposure.

Action of aggressive substances, chemicals, solvents, acids.

The equipment must be transported in packaging which protects it against damage or moisture, e.g. in bags

made of impregnated fabric or in steel or plastic suitcases or crates.