BASIC PRINCIPLES OF USE AND GENERAL SAFETY RULES

Rope working diameter is indicated on the device's body. Do not use ropes larger diameter then specified because

of damage of pulley or incorrect working. Use only with textile ropes. Do not use with wire ropes or chains.

Never use the pulley to lift people,

Never lift the load above people or if any people are around,

Never load the device with a load greater than the value indicated on its body.

Never lift any load of unknown weight,

Never use visibly damaged and deformed pulleys,

Never use the pulley to anchor any loads,

Never allow a load to swing, jerk or vibrate,

Never pull the working rope, when it leans against an edge, Always make sure that the load-bearing structure is

capable of handling the WLL,

Always warn people around that you start operating,

Always make sure that a load is properly supported in a stable position once it is lifted.

Always make sure that pulleys are operated only by people who are physically fit, authorized, trained and aged

above 18,

Always make sure that the rope length is enough for the task to be completed,

Always make sure that a load is suspended correctly,

Always make sure that swivel parts of the pulley in working positions are connected by means of a snap hook and

will not open once the WLL is applied.

Always use the device only to lift the load manually

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

personal protective equipment shall only be used by a person trained and competent in its safe use.

personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use.

a rescue plan shall be in place to deal with any emergencies that could arise during the work.

it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent.

any repair shall only be carried out by equipment manufacturer or his certified representative.

personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended.

personal protective equipment should be a personal issue item.

before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment components to avoid

accidental loosening or disconnecting of the components.

it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another.

before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates correctly before

it is used.

during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting, especially take into

consideration:

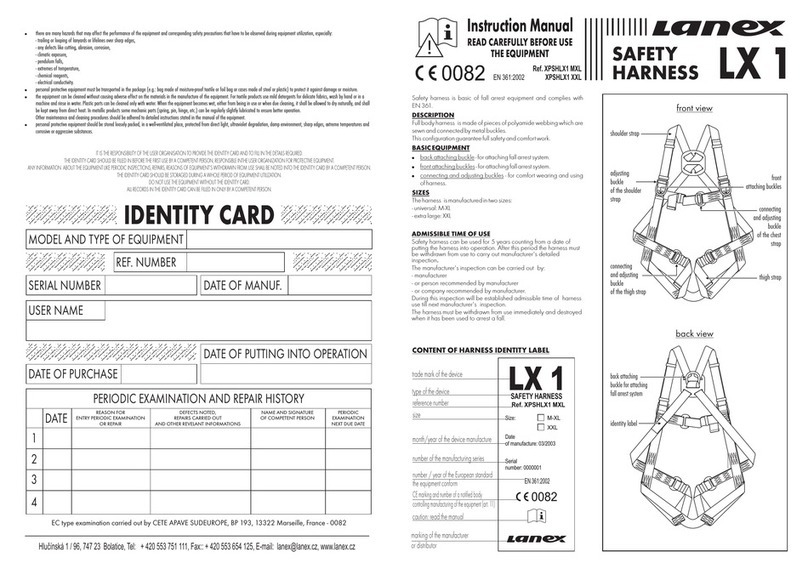

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops;

- in energy absorbers - attaching loops, webbing, seams, casing, connectors;

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements;

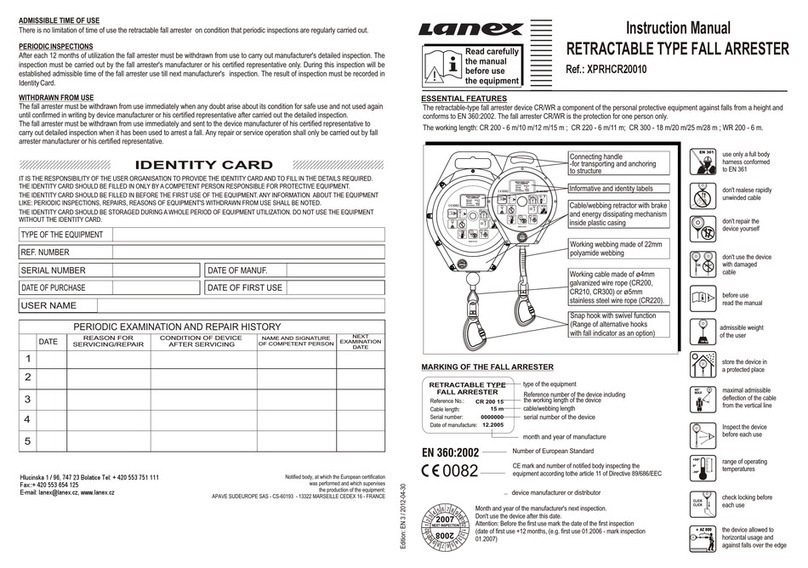

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector;

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber;

- in connectors - main body, rivets, gate, locking gear acting.

after every 12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be carried out by

a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

In case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his authorized

representative.

regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the equipment.

during periodic inspection it is necessary to check the legibility of the equipment marking.

it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for maintenance, for periodic

examination and for repair in language of the country in which the product is to be used.

personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in writing by equipment

manufacturer or his representative after carried out the detailed inspection.

personal protective equipment must be withdrawn from use immediately and destroyed when it have been used to arrest a fall.

,

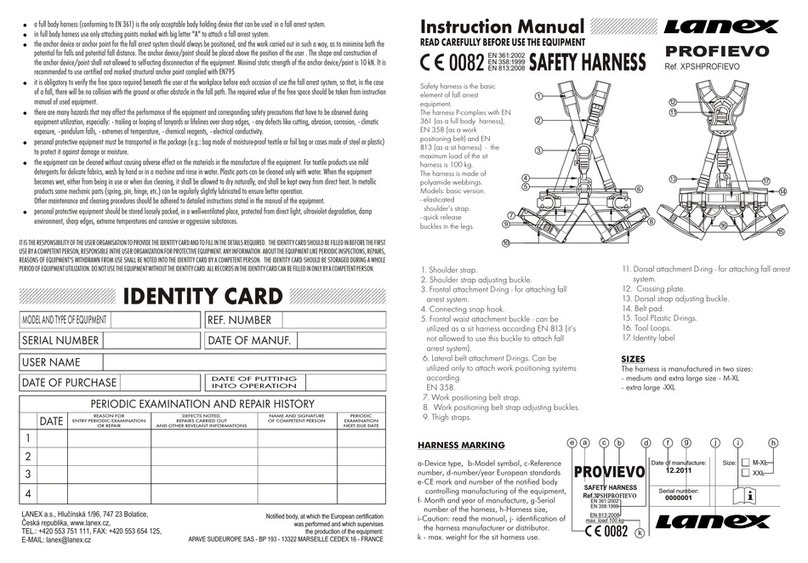

a full body harness complied with EN 361 is the only acceptable body holding device that can be used in a fall arrest system.

the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimize both the potential for falls and potential

fall distance. The anchor device/point should be placed above the position of the user . The shape and construction of the anchor device/point shall not allowed to self-acting

disconnection of the equipment. Minimal static strength of the anchor device/point is 10 kN. It is recommended to use certified and marked structural anchor point complied with EN795.

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT

BASIC PRINCIPLES OF USE AND GENERAL SAFETY RULES

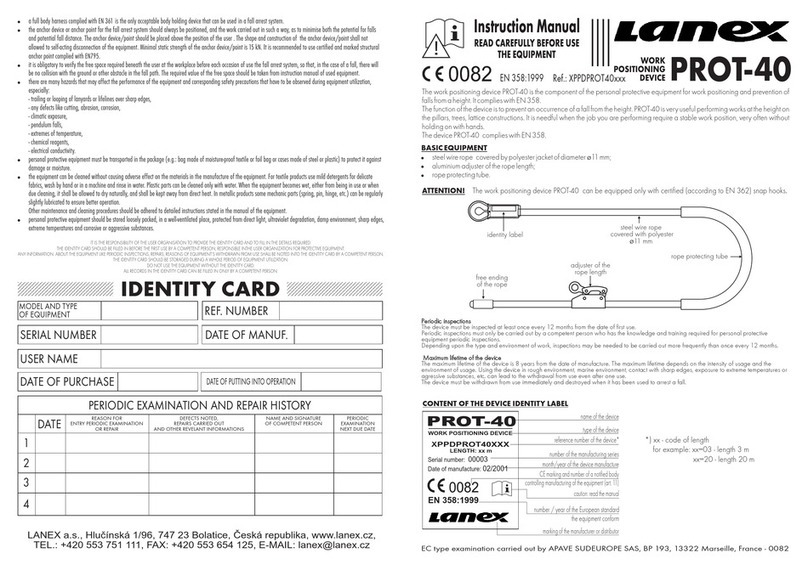

- The device is not designed for use as a personal fall arrester equipment.

- The device is subject to the EU Directive 89/686/EEC.

- Prior to each application the device should be examined carefully. The inspection should be carried out by the user of

the device. Should any defects be found or incorrect operation of the device detected, the device should be withdrawn

from use.

- While the device is in use it should be protected against mechanical, chemical and thermal damage.

- Any upgrading or modification of the device without the prior written consent by the manufacturer is forbidden.

- Any repairs should be done solely by the manufacturer of the device or his authorised representative.

- It is forbidden to connect any elements of the device which may mutually disturb any of their functions.

- There are many hazards which may affect the operation of the device, therefore it is necessary to apply any means of

precaution and follow safety rules to ensure correct operation of the device. The following should particularly be in

focus:

•Kinks, cuts or wear of the lanyard

•Exposure to climatic conditions

•Extreme temperatures

•Chemical reagents

•Electric conductivity, etc.

- This product is designed for use in normal atmospheric conditions (-40ºC … +50ºC).

- Humid environment and icing may reduce the strength and load-carrying capacity of the device. In case of operation

in an aggressive environment please contact the manufacturer or vendor.

- The structure on which the device is mounted must be stable. The static strength of the structure element must be at

least twice greater than the weight of the hoisted load.

- The durability of connections between the structure, the pulley and the load should be checked to avoid accidental

disconnecting of any of the elements.

- Particular care should be taken when blocking the lanyard with the use of the jaw cleat, do not allow any employees

within the area directly beneath the hoisted load.

INSPECTION

Inspection of the device is necessary to maintain the proper state of repair of the equipment and to ensure user safety,

which depends on continuous efficiency and durability of the device.

Prior to any use of the pulley, it is necessary to:

- Inspect all elements of the device in terms of any damage (mechanical, chemical and thermal), excessive wear,

corrosion, cuts, wear, incorrect operation.

- Check connections between elements to avoid accidental loosening or disconnection of elements.

In case any irregularities are found the device should be withdrawn from use.

STORAGE

Pulleys should be stored dry and clean, away from any chemical factors,

The device should be stored without any load suspended,

Remove any dust, water and contamination with a potential of damaging anti-corrosion layer during the device

storage.

TIME OF USE

Maximum time of use of the devices is indefinite.

It is recommended to use the device for 5 years from the date of manufacture engraved on its housing.

LUBRICATION

The device is fitted with plastic slide bearings that require no lubrication. If rolling resistance on the main roller

increases, blow out the pulley with compressed air and inject small quantity of a lubricant, e.g. WD40 in between the

roller and the body.MAINTENANCERope pulleys are maintenance-free, except for possible lubrication as indicated

above. The manufacturer provides no spare parts for this products, and performs no repairs of the device. If a pulley is

damaged, take it out of service and replace with a new one.

SHIPMENT

The device should be shipped in packaging (e.g. in a bag resistant to moisture or plastic bag or in crates made of steel

or plastic), to protect it against damage and moisture.