6.

Function: Heating

The device is controlled by digital temperature control technology, which has two separate safe

circuits.

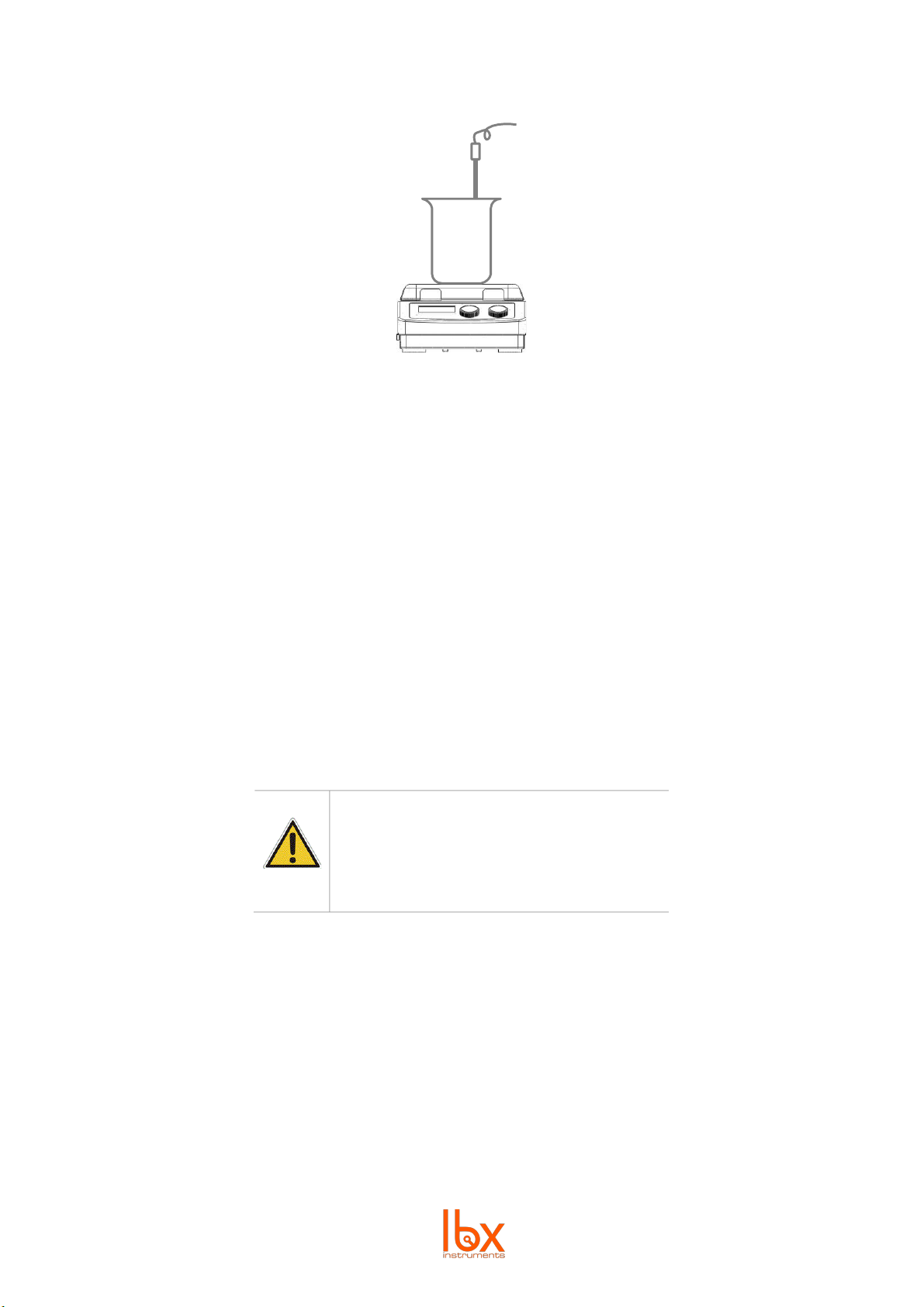

•If an external sensor PT1000 is used, always connect it to the device BEFORE turning the power

on and submerge it into the sample BEFORE starting to heat (see section 6.1).

•Turn the unit on by pressing the ON/OFF switch.

•Select the target temperature by slowly turning the temperature knob towards the desired value.

•When the heating function is ON, the LED screen displays the target temperature value for 5

seconds and then shifts to the real value. The Heat LED also lights up until the set temperature is

reached.

•At the end of the operation, turn off the heating function by turning the temperature knob all the

way to the left.

•Turn off the unit by pressing the ON/OFF switch.

The heating function will be stopped automatically under abnormal conditions. The device has a fixed

safety temperature of 580ºC; therefore, it automatically stops heating once that temperature is

reached.

In that case, please follow the following instructions:

•Switch OFF the instrument.

•If working with an external temperature sensor, make sure it is inserted into the media to be

heated.

•Switch ON the instrument and run the heating function.

If the heating function is still not working, please contact the manufacturer/supplier for technical

support.

Generally, the LED display does not indicate the actual temperature of the sample in the vessel or on

the hotplate surface. There are temperatures differences between the following:

•Hotplate center and outer edge.

•The sample in the container and the hotplate.

In order to ensure an accurate measurement of the temperature inside the container, use the

external temperature sensor PT1000.