·Ensure that the main cable does not touch the surface.

·Do not damage the power cord and always use the specified one. In case of damage, the

power cord must be replaced.

·Do not unplug the power cord during operation.

·Unplug the cord before maintenance, after use, and if the instrument is running abnormally.

·Do not touch the power plug with wet hands.

·Wear gloves when repairing and maintaining the instrument.

Other necessary considerations:

·When touching the inner wall of the door, do it carefully, as it may be hot.

·The internal parameters must be set by the specific management person to prevent the function

of the controller program from being disturbed by an unknown setting.

·The equipment must be placed at least 20cm away from the wall and from any objects.

·Open and close the door gently to prevent damage to the equipment.

·Do not expose the equipment surface to volatile chemicals.

·Keep the equipment clean, both the inside and the outside.

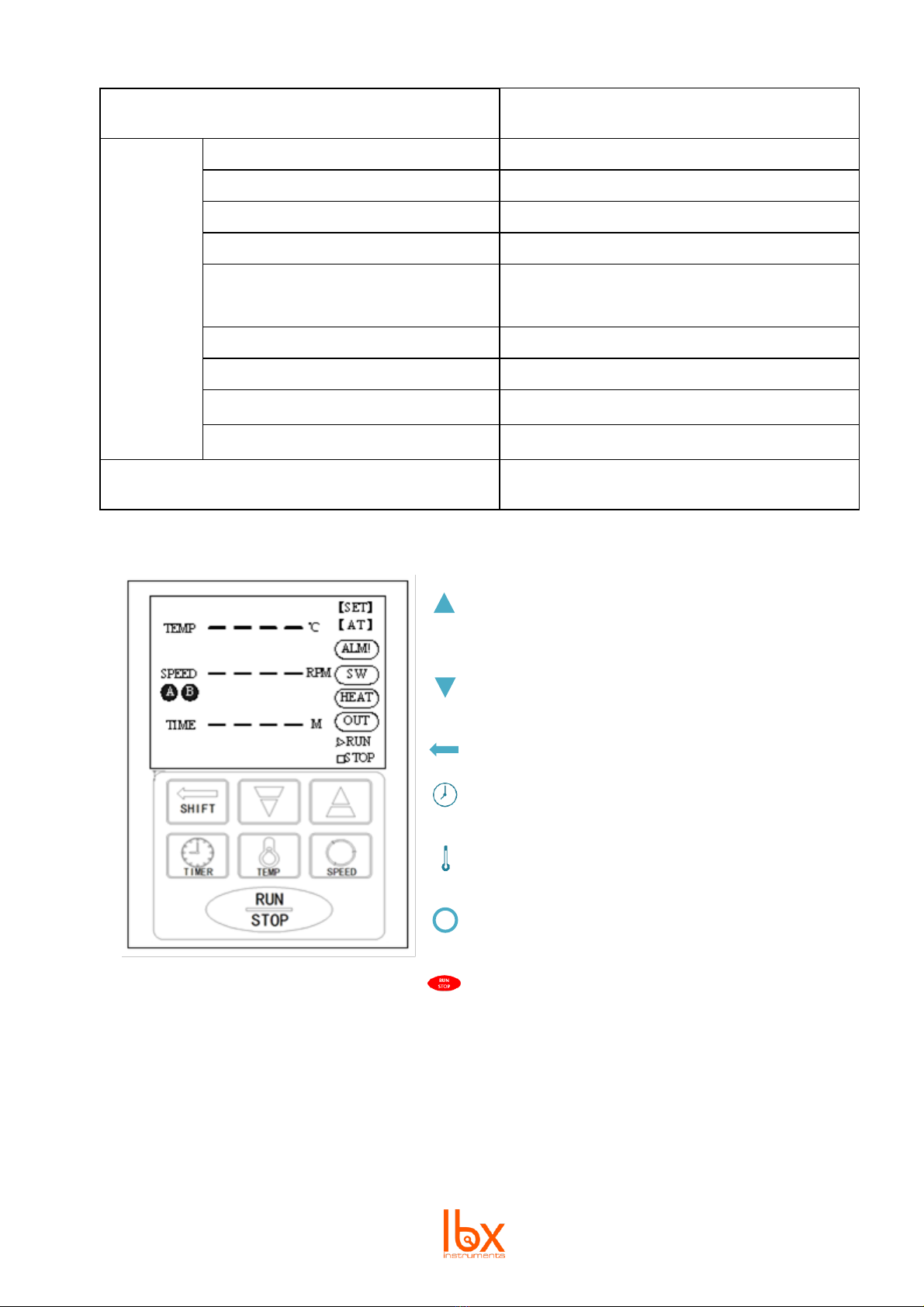

Safety alarms:

·In case of a controller block, Holzer error, busbar under voltage, busbar over voltage or

communication failure, the speed bar will show the fault code and the controller will

automatically stop.

·In case of a temperature or speed alarm, the identifier ALM1 will light up and the buzzer

sound will go off. Stop it by pressing any key.

·When turning off the equipment, always press to stop any ongoing functions before

turning off the device.

·In case of a fault of the temperature sensor or the controller itself, the indicator –will display.

Carefully check the temperature sensor and its wiring.