-Make sure that the glass assembly has no stress due to the risk of breaking from causes as:

- Mechanical hazards from the outside

- Excess temperature in the equipment itself

-The temperature must be always set, at least, 25°C below the ignition temperature of the materials

used

-Check equipment and accessories before each use and do not use components in poor condition

-Safe operation of the equipment is only guaranteed with the accessories described in chapter "Packing

list". The accessories must be firmly attached to the equipment and cannot come loose

-Always turn off the power before installing accessories

-Do not cover the ventilation outlets of the unit to ensure adequate cooling of the rotary evaporator

- Adapt the quantity and type of solvent to the size of the distillation equipment

- Please know that high concentrations of gases, steam or particular matters can escape through the

cooler. Avoid this risk by using, for example, cold water traps, gas wash bottles or an effective extraction

system, such as showcases

- The glassware is designed for operations with maximum vacuum of 10 mbar. The glass must be cooled

down before its removal and reuse

- Avoid formation of peroxide. Organic peroxides can accumulate in the distillation and generate

exhaust residues that explode easily when decomposed

- Never heat the evaporation flask in the bath without first actuating the rotary motion. In this way, you

will avoid possible losses of your sample

- Pay attention to the temperature setting; never leave the equipment unattended during operation and

with the heating function on

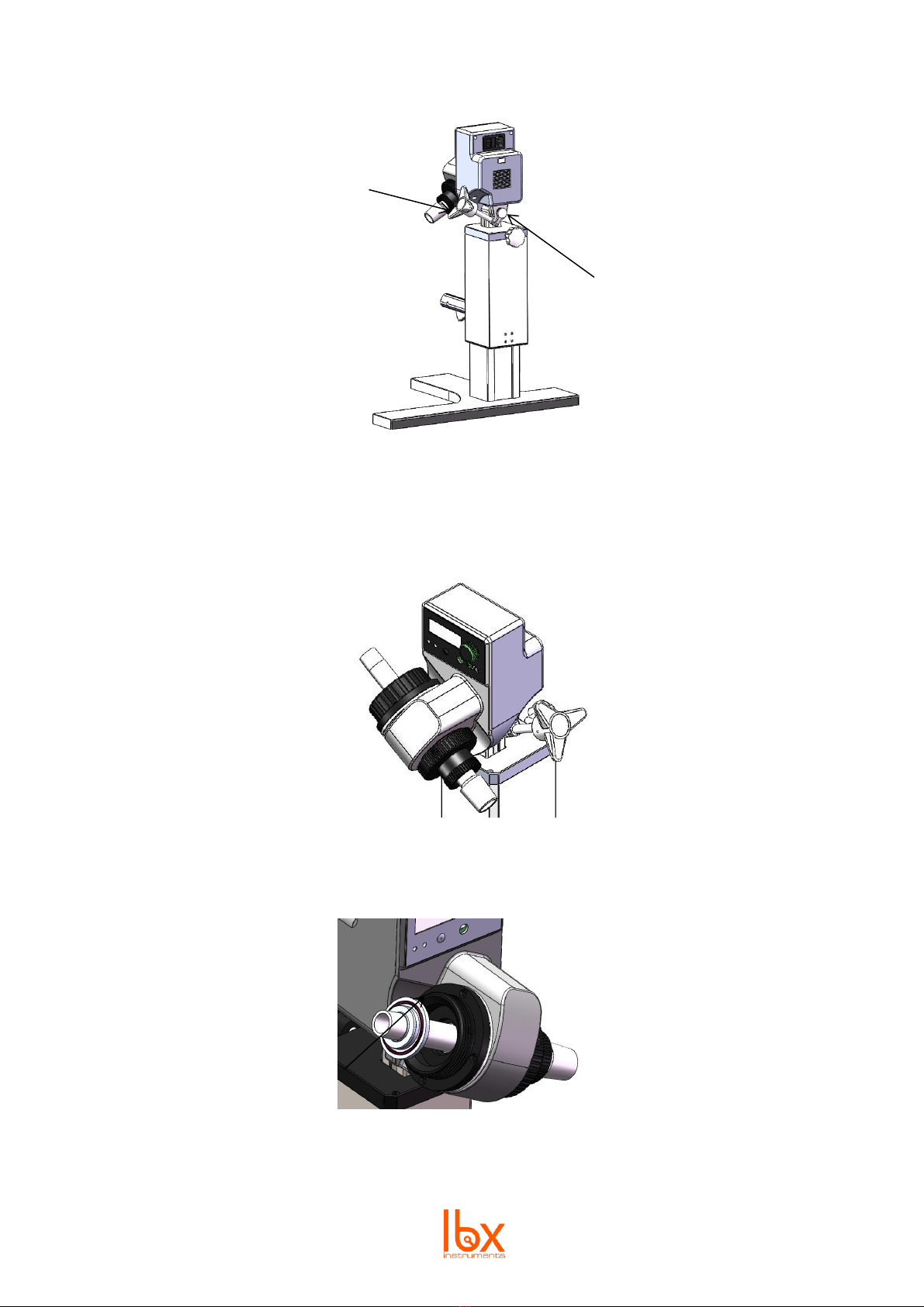

- Do not handle the rotary evaporator when the rotating piston is working. It is recommended to

gradually increase and/or decrease the rotation speed if situations such as an irregular operation occur

- The equipment can only be disconnected from the power outlet by pulling the plug base, not the cord

- The voltage indicated on the equipment must correspond to the electrical network used

- Make sure that the main power cord is not in contact with the heating surface. Do not cover the

equipment

- Keep the equipment away from high magnetic fields