IMPORTANT WARRANTY INFORMATION PLEASE READ

FILL OUT AND RETURN ENCLOSED WARRANTY CARD

THIS WARRANTY COVERS

Big Bite®

THE WARRANTY IS EXTENDED TO THE ORIGINAL PURCHASER ONLY.

WARRANTY DURATION: This product is warranted to the original purchaser for a period of two (2) years from the original purchase

date. EACH UNIT COMES WITHA WARRANTY CARD, WHICHMUST BE FILLED OUT COMPLETELY AND RETURNED IMMEDIATE-

LY, WITH A COPY OF THE PURCHASING RECEIPT. FAILURE TO RETURN YOUR WARRANTY CARD WILL LIMIT WARRANTY TO 90

DAYS WITH PROOF OF PURCHASE.

WARRANTY COVERAGE: This product is warranted against defective materials or workmanship.The warranty is void if the product

is also

void if damaged in shipment or by other causes not arising out of defects in the materials or workmanship. This warranty does not

extend to any units which have been in violation of written instructions furnished.This warranty covers only the product and its

WARRANTY DISCLAIMERS: This warranty is in lieu of all warranties expressed or implied, and no representative or person is

authorized to assume any other liability in connection withthe sale of our products. There shall be no claims for defects or failure of

performance under any theory of sort, contract or commercial law including, but not limited to negligence, gross negligence, strict

liability or breach of contract.The manufacturer declines all responsibility for damage to persons, things or animals arising from the

anytime to

the models while maintaining the main characteristics described herein. The manufacturer also declines all responsibilityfor any

errors in compiling this manual.

WARRANTY PERFORMANCE: During the warranty period, a product witha defect will either be repaired or replaced after the product

has beeninspected by an LEM Service Technician. LEM RESERVESTHE RIGHT TO REFUSE WARRANTY PERFORMANCE OR PRODUCT

EVALUATION UNLESSTHE ORIGINAL SALES RECEIPT ORTHEWARRANTY CARD IS ON FILE. The repaired product will be in warranty for the

balance of the warranty period. No charge will be made for such repair or replacement.

IMPORTANT NOTICE: If any parts are missing or defective, please contact our Customer Service Department for assistance at

877-536-7763 (M-F 8:30am to 4:30pm EST). DO NOT RETURN TO THE STORE WHERE THE PRODUCT WAS PURCHASED. LEM

sale items where the seller may not be able to guarantee full functionality or completeness of the unit.

LEM PRODUCTS MERCHANDISE RETURN POLICY WARRANTY SERVICE: To obtain service under terms of this warranty, please

contact us at 877-536-7763 to obtain authorization prior to returning the merchandise. No merchandise will be accepted without

prior authorization. Prior to returning the product for warranty repair the product must be thoroughly cleaned and free from any food

particles or other debris. Failure of the purchaser to comply with this standard may result in the unit being returned without repair.

In some cases, a $50 cleaning surcharge may apply. Please return the product prepaid in the original packaging if possible, enclose a

copy of your receipt, (keep a copy of your proof-of-purchase for your records) and include a written explanation of the issue. Ship to

LEM Products, 4440 Muhlhauser Road, Suite 300, West Chester, OH 45011. LEM Products is not responsible for damage incurred in

shipping, make certain to pack product properly. Return shipping charges are the responsibility of the purchaser.Packages returned to

LEM should be insured for the value of the product to cover any damages that may occur during shipping.

Revised January 8, 2020

GENERAL WARNINGS AND SAFETY INFORMATION

2LEM Products • West Chester, OH45011 • PH: 877-536-7763 • lemproducts.com

IT IS IMPORTANT TO READ AND UNDERSTAND ALL OF THE INSTRUCTIONS AND SAFEGUARDS PRIOR TO USE

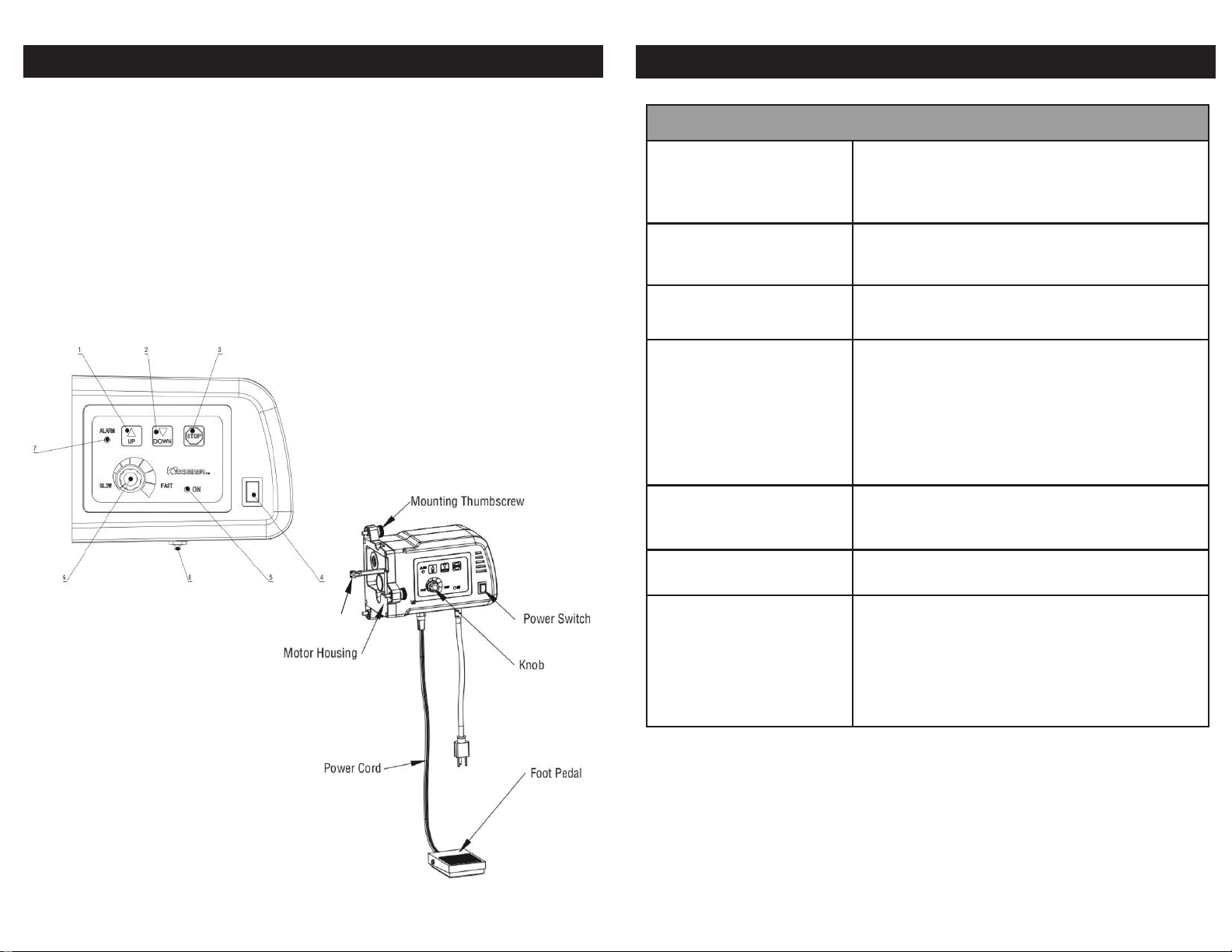

1. Always ensure that the motor is properly assembled and safely set up before use.

2. DO NOT leave the motor unattended if it can be switched on and operated.

3. CAUTION: This appliance is not recommended for use near or bychildren or persons with certain disabilities. Set up and

store the motor outof reach of children. When not in use, store device in a secure and dry place out of reach of children.

4.

Check for damaged parts before using the product. Check that all parts are operating properly and perform the

intended functions. Check for binding of moving parts, mounting and any other conditions that may apply.

5. WARNING: Heavy object, to avoid muscle strain or back injury, use lifting aids and proper lifting techniques when

moving motor.

6. The appliance must be connected to an 120V AC electric supply only.

7.

For your safety, this unit is equipped with a 3-pronged, grounding plug and must be plugged into a properly grounded

outlet. If your outlet is not of the proper type, it is your responsibility to have the outlet and wiring changed to the correct

8. Using this appliance with an extension cord may cause a decrease in electrical current, causing the motor to be over

9. Do not operate with a damaged cord or plug, after the unit malfunctions, has been damaged in any way or if motor

has been immersed in water or other liquid. Return unit to LEM Products for assessment and repair.

10. Always unplug unit when not in use, when changing parts or cleaning.

11. Never unplug by pulling on the power cord, always pull directly on the plug itself.

12. Do not let cord hang over edge of table or counter, contact sharp edges or touch hot surfaces.

13. Indoor use only. To protect against the risk of electrical shock, never immerse the motor in water and do not expose the

motor to rain or moisture. WARNING: In the event the motor should fall into water, remove the plug from the wall

socket before attempting to remove the motor from the water. If submergence occurs, have the motor examined by an

authorized technician before use.

14. To protect against the risk of electrical shock, DO NOT use the motor if your hands are wet or if you are standing on a

DO NOT submerge or use the motor near liquids.

15. The appliance is designed for domestic use and not for commercial purposes.

16.

safer at the rate for which it was designed.

17. Use the motor with the supplied accessories only. WARNING: The use of attachments not recommended or sold by the

manufacturer may cause injury, damage to personal property, and may void your warranty.

18. WARNING:

impair user’s ability to properly assemble or safely operate the appliance.

19. The manufacturer declines any responsibility in the case of improper use of this product. Improper use of this product

voids the warranty.

20. Avoid contacting moving parts. Wait until all parts have come to a complete stop and disconnect from the power source

21.

Keep your work area clean and well lit. Cluttered work benches and dark work areas may cause accidents or injury.

22. DO NOT operate the motor for more than one hour at one time. After one hour of continuous use, allow a few minutes

for the device to rest before next use.

23. WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot cover

all possible conditions or situations that could occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product, but must be supplied by the operator.

24. Thoroughly hand-wash all removeable parts in warm soapy water prior to use. Do not soak. NOT DISHWASHER

SAFE (discoloration may occur).

25. Tie back loose hair and clothing. Remove neckties, rings, watches, bracelets or other jewelry before use.

26. Use unit on a level, stable surface to prevent tipping. Never move the unit while unit is in use.

27.

SAVE THESE INSTRUCTIONS

11

LEM Products • WestChester, OH 45011 • PH: 877-536-7763 • lemproducts.com