2Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

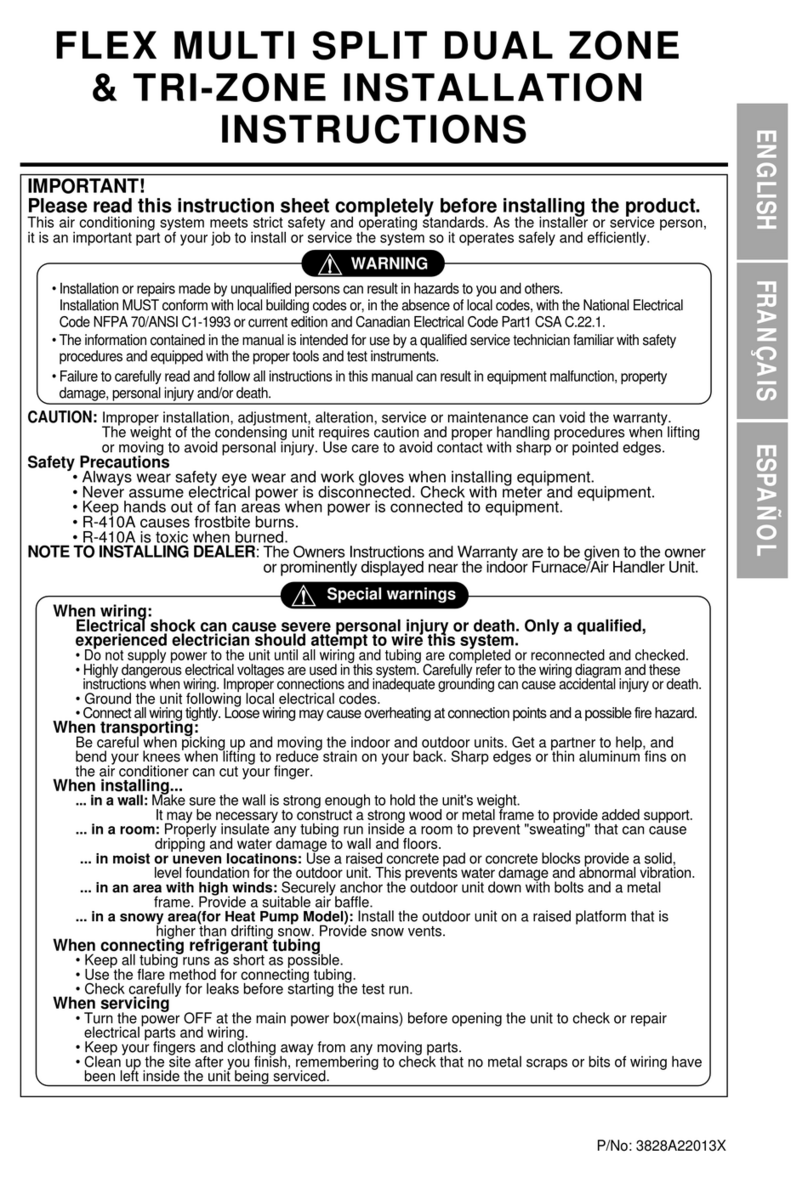

Safety Precautions..........................................................................................................................................3

Dimensions .....................................................................................................................................................5

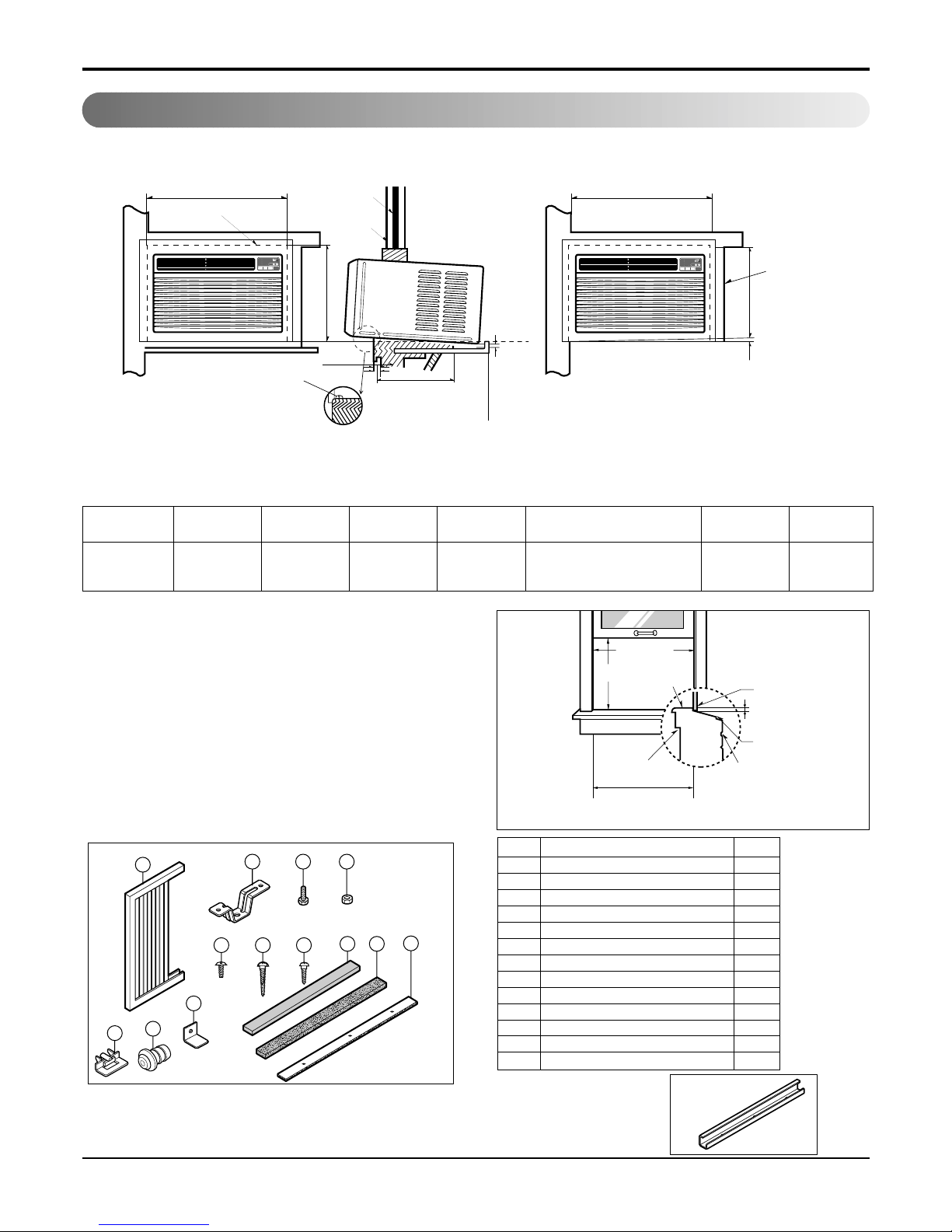

Outside Dimensions...................................................................................................................................5

Product Specifications ..................................................................................................................................6

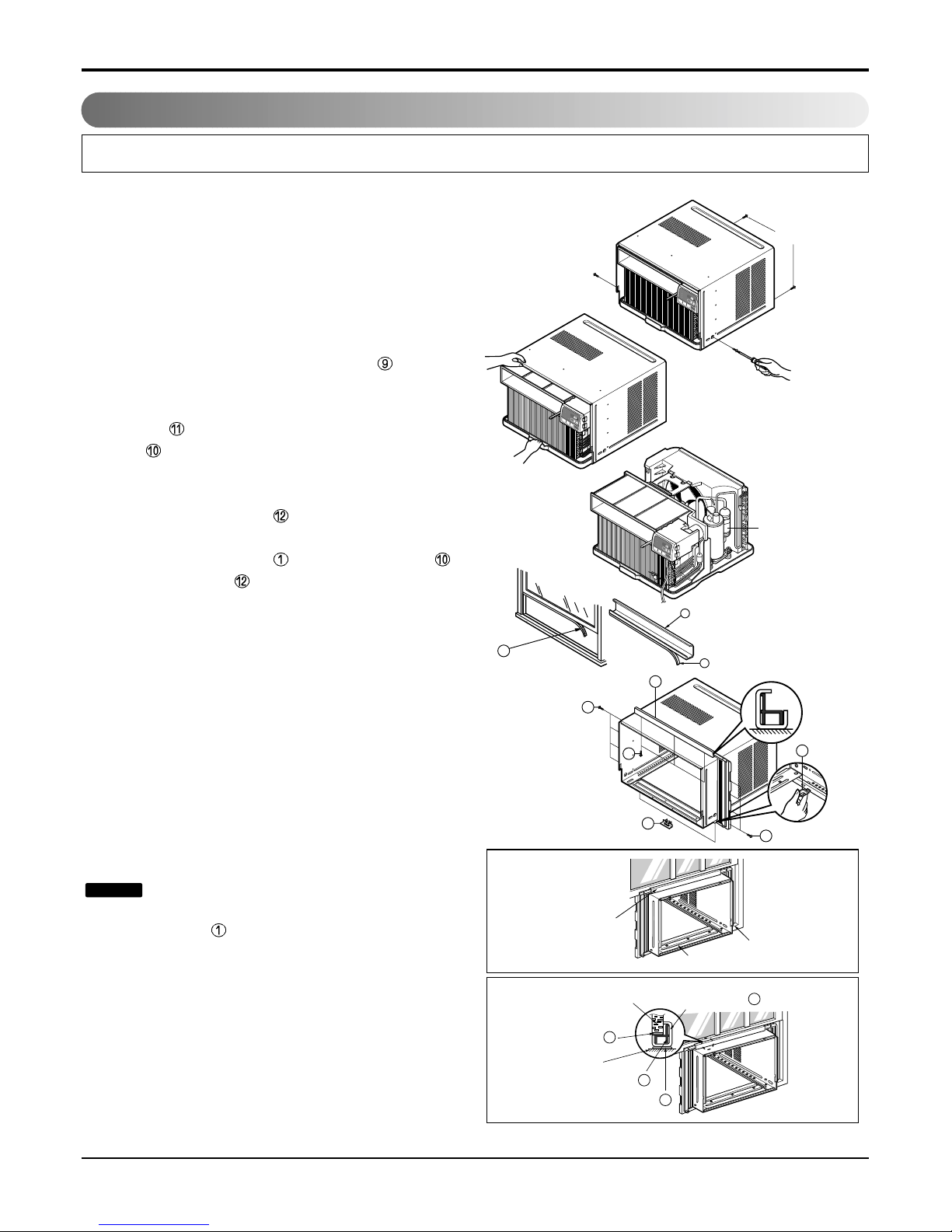

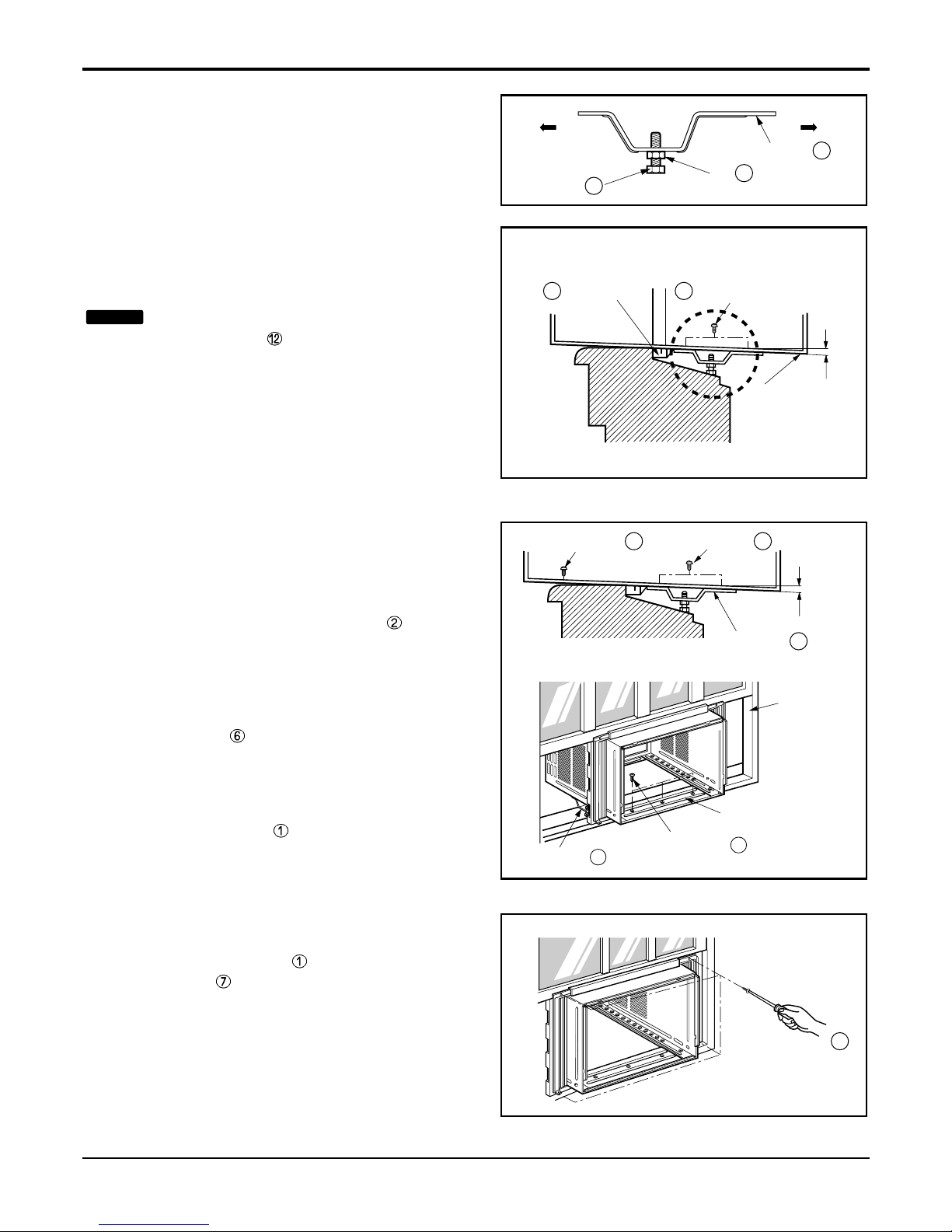

Installation.......................................................................................................................................................7

Select the Best Location ............................................................................................................................7

Installation Check.......................................................................................................................................7

How to Secure the Drain Pipe....................................................................................................................7

How to Install..............................................................................................................................................8

Suggested Tool Requirements...................................................................................................................9

Operation ......................................................................................................................................................12

Function of Controls.................................................................................................................................12

Disassembly ..................................................................................................................................................13

Mechanical Parts......................................................................................................................................13

Air handling Parts.....................................................................................................................................14

Electrical Parts .........................................................................................................................................15

Refrigerating Cycle...................................................................................................................................17

Schematic Diagram.......................................................................................................................................20

Electronic Control Device.........................................................................................................................20

Wiring Diagram.........................................................................................................................................21

Components Location ..............................................................................................................................22

Troubleshooting Guide.................................................................................................................................23

Pipeing System ........................................................................................................................................23

Troubleshooting Guide .............................................................................................................................23

Electrical Parts Troubleshooting Guide ....................................................................................................26

Electrical Parts .........................................................................................................................................30

Exploded View ..............................................................................................................................................36

Replacement Parts List ................................................................................................................................37

![LG LZ-H080GBA2 [ARVU053ZEA2] User manual LG LZ-H080GBA2 [ARVU053ZEA2] User manual](/data/manuals/27/2/272ct/sources/lg-lz-h080gba2-arvu053zea2--manual.jpg)