Linak TECHLINE LA36 Instruction manual

Other Linak Controllers manuals

Linak

Linak ACTUATOR LA36 Instruction manual

Linak

Linak ACTUATOR LA36 User manual

Linak

Linak DPA User manual

Linak

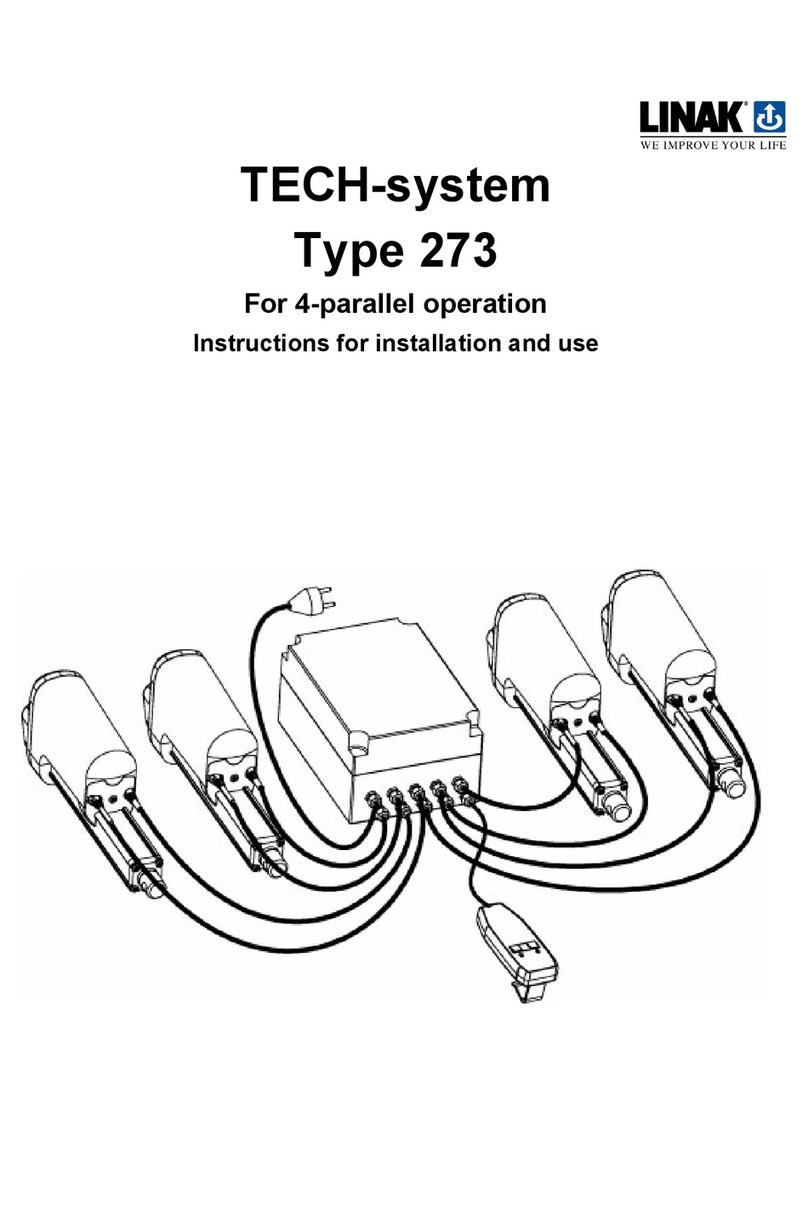

Linak 273 Series User manual

Linak

Linak DESKLINE DL1A User manual

Linak

Linak HB100 User manual

Linak

Linak ACTUATOR LA36 Instruction manual

Linak

Linak 239 Series User manual

Linak

Linak MEDLINE LA32 Operational manual

Linak

Linak Homeline TWINDRIVE TD5 Standard User manual

Linak

Linak TD4 User manual

Linak

Linak Homeline LA18 User manual

Linak

Linak LA12 User manual

Linak

Linak TECHLINE LA25 User manual

Linak

Linak TECHLINE LA37 User manual

Linak

Linak TECHLINE LA33 User manual

Linak

Linak HOMELINE KA20IC2 User manual

Linak

Linak BusLink LA14 User manual

Linak

Linak ACTUATOR LA36 User manual

Linak

Linak TWINDRIVE TD1 Operational manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions