Page Number - 3

Airless Spray System®

Form 402976

will be disabled and the stored Accumulator pressure will

force the Measuring Piston to move, forcing the lubricant out

of the Measuring Valve outlet, through a hose or tube into the

Spray Head, through the Solenoid Valve and out the nozzle

onto the work surface. When the Timer times out, the Spray

Solenoid will close and the Pressure Switch, sensing low

pressure, will turn on the Pump to refill the measuring

chamber for another cycle.

Heating the Airless Spray System

To maintain an optimal and predictable spray pattern, the

measuring valve, spray head and interconnecting supply

line should be kept warm. The temperature of the lubricant

should be kept as constant as possible for a consistent

spray pattern. The amount of heat used is dependant upon

the characteristics of the lubricant and the ambient

temperatures to be encountered.

Heating ports are provided in the spray head and measuring

valve to facilitate the application of heat to the system.

These ports may be used to circulate a warming fluid in a

series loop through the spray head and measuring valve. A

heat trace line may also be part of this loop to keep the

interconnecting supply line warm as well.

The heating loop may consist of the return or supply line of a

hydraulic circuit which has enough fluid circulating through it

to keep the components warm. The engine cooling system

may also be used. Temperatures should be as consistent

as possible once the machine has warmed up and is in

operation.

Spray tips should be selected on the basis of the lubricant

temperature once the machine is warmed up and in

operation. Generally, as the lubricant gets hotter, the spray

pattern will get wider and become more atomized, for a

given spray tip. If the lubricant is too cold, the lubricant spray

pattern will be very narrow, become a solid stream, or will

not spray at all.

Lubricants

This system was designed and tested with grease

lubricants. Lubricants with high viscosities, large particles

and with very tacky properties should be avoided. Any

lubricant should be tested in the system before the lubricant

is committed to long term use.

Lubricants with large particulates may cause blockages in

the spray tips and valves used in the spray system. Any

particulates will act as an abrasive and cause premature

wear on these components.

A lubricant change may require a change in spray tips. A

change in lubricant properties will change the spray

characteristics.

The controller may also be used to synchronize timing of

the spray with the movement of a machine part.

The measuring valve and spray head assemblies are

supplied with ports for conducting heated fluid. These

heat ports may be connected into an existing source of

heat, such as hydraulic return lines or engine coolant

lines to provide heat for predictable spray patterns. A

relatively constant temperature fluid (while in operation)

between 80° F min. and 160° F. max. should be used.

Spray tips should be selected based on the lubricant to

be sprayed and the temperature of the lubricant as it

passes through the spray system.

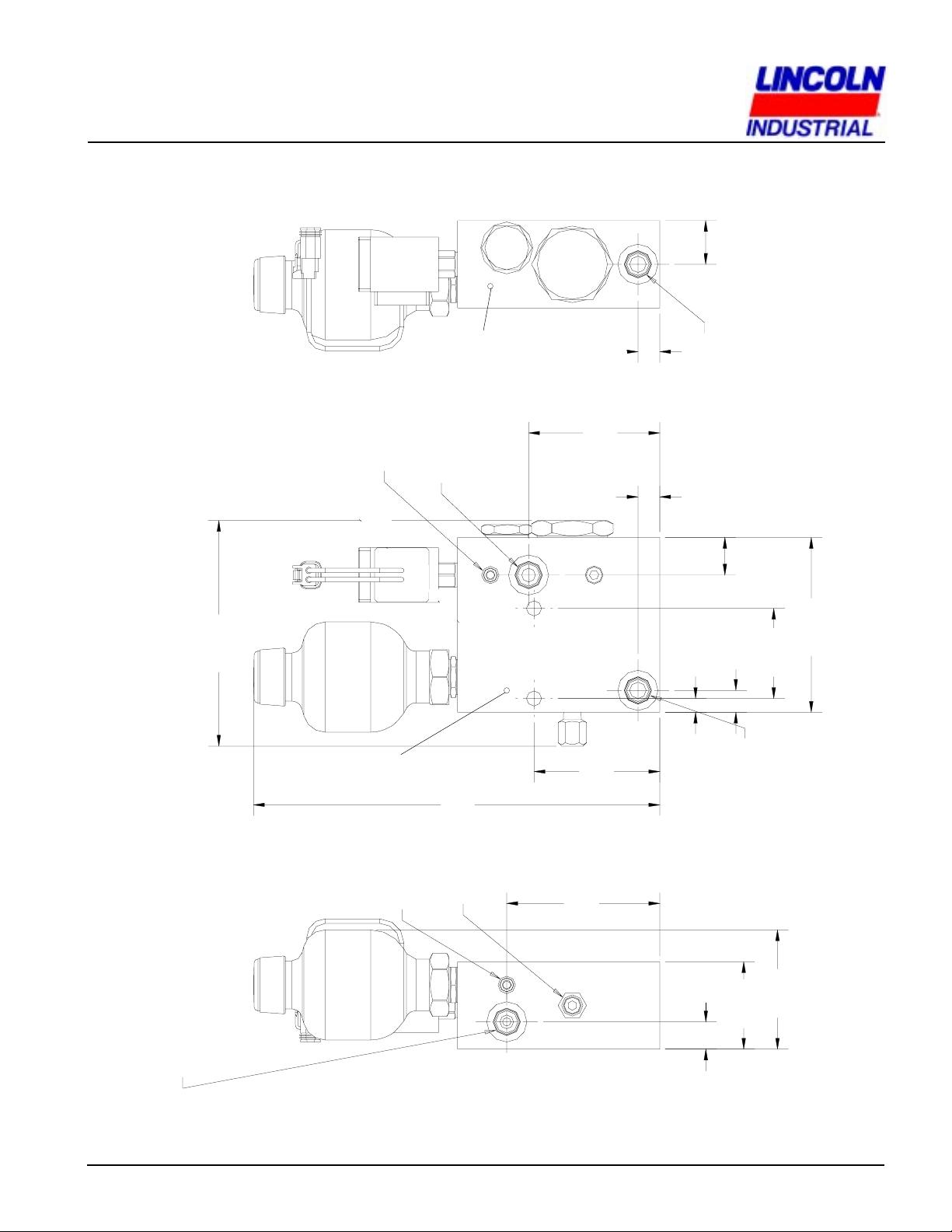

Product Specifications

Output per Cycle - .500 in³ max. (8.2 cc)

(dependant on spray ON time)

Pressure Switch Preset

Pressure - 4500 psi (310 bar) max.

Output Pressure - 4500 psi (310 bar) max.

Operating Temperature* - -20° to 160° F (-28° C to 71° C)

Operating Voltage - 12 VDC

Initial Current - 1.2 amps

Material Inlet

(measuring valve) - 3/8 SAE J-1926 (9/16 - 18 UNF)

Material Outlet

(spray head) - 1/2 SAE J-1926 (3/4 - 16 UNF)

Interconnecting Ports - 3/8 SAE J-1926 (9/16 - 18 UNF)

Pressure Switch Contacts - 5 Amps @ 125/250 VAC

Initial Hydraulic Charge

(measuring valve) - 2000 PSIG (138 bar)

Initial Pneumatic Charge

(measuring valve) - 1500 PSIG (103.5 bar)

* To achieve consistent spray material temperature, pump to

be maintained at +80° F to 120° F.

Spray tip must be ordered separately and selected based on

lubricant and pattern desired.

OPERATION

When the Pressure Switch, mounted on the Measuring Valve

senses low pressure on the Measuring Valve Chamber, it

signals the control unit to turn on the pump and begin filling

the Measuring Chamber with lubricant. Due to the hydraulic

and gas pre-charge on the Measuring Valve and

Accumulator respectively, initial charging of the lubricant will

begin at 2000 psi. The Pump will continue to charge the

Measuring Chamber, moving the Measuring Piston in its

bore against the precharged hydraulic circuit and

accumulator pressure. The Check Valve will prevent any

lubricant from escaping the Measuring Chamber, and the

Solenoid Valve will prevent lubricant from flowing out of the

Spray Nozzle. When the pressure inside the Measuring

Chamber reaches the pressure switch set point, the Pump

is turned off, the Spray Valve is enabled and a ready light is

turned on, indicating the system is ready to spray. A push

button or other device is used to initiate the spray cycle at

the Control Unit. When the spray cycle is initiated, a timer

will begin to time, the Solenoid Valve will open, the Pump