PL-2000 Owner's Manual

4

Description

The Lincoln PL-2000 is a programmable lubrication

system that can supply grease to a maximum of 18

fittings. It can dispense NLGI #2 grease at timed

intervals from 2 hours to 30 days. Each cycle of the

system dispenses .012 in³. of grease per outlet.

The lubricant reservoir is divided by a special dia-

phragm, with the upper portion of the reservoir

precharged for life with nitrogen gas. Filling the

reservoir with grease provides the pressure neces-

sary to dispense lubricant to the fittings.

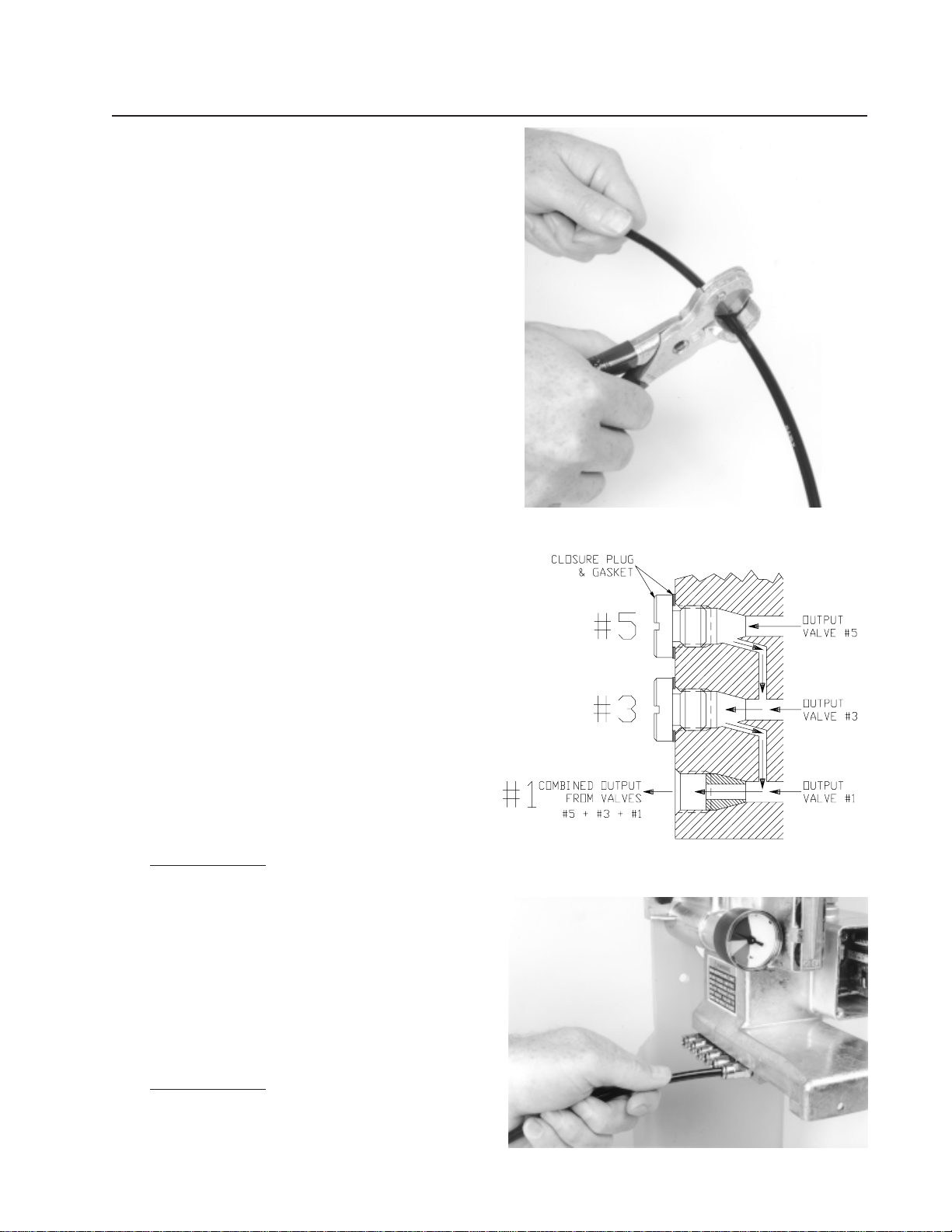

A signal from the system timer opens a solenoid

valve and allows lubricant from the reservoir to flow to

a divider valve. When all grease fittings have re-

ceived lubricant, an internal cycle switch turns the

system off, completing one lubrication cycle.

The lube timer has a memory. If power is turned off

for less than 72 hours, it “remembers” where it

stopped, and will restart at the same point when

power is restored. (This prevents over-lubrication of

the machine if power is switched on and off over short

periods of time.) If power is off for more than 72

hours, the timer will begin a lube cycle when power

turns on, then start timing toward the previously

selected lubrication interval.

Installation Instructions

Use the following recommendations to select a

mounting location for the PL-2000 lubricator.

• Keep the feed lines as short as possible.

• Provide access to fill, clean, and monitor the

PL-2000.

• Allow adequate room for mounting and connecting

feed lines to the PL-2000.

• Installing the PL-2000 with the reservoir on top is

preferred, but it may be installed in any orientation

without affecting its operation.