6 Connect the remaining end of the high

pressure hose to the special male thread

on the universal swivel (6) and tighten

securely.

7 Connect the 1/4-18 NPT male thread

on the universal swivel (6) to the control

valve (1) and tighten securely.

8 Install the grease coupling and extension

tube into the outlet end of the control

valve (1) and tighten securely.

9 Install the air nipple (4) into the air inlet

of the pump and tighten securely.

10 Attach the air coupler (5) onto a suitable

3/8 in. inner diamter (minimum) air hose

and tighten securely. Do not apply air

pressure at this time.

11 Assemble the follower (17) per the

instructions in section K5, page 6 series.

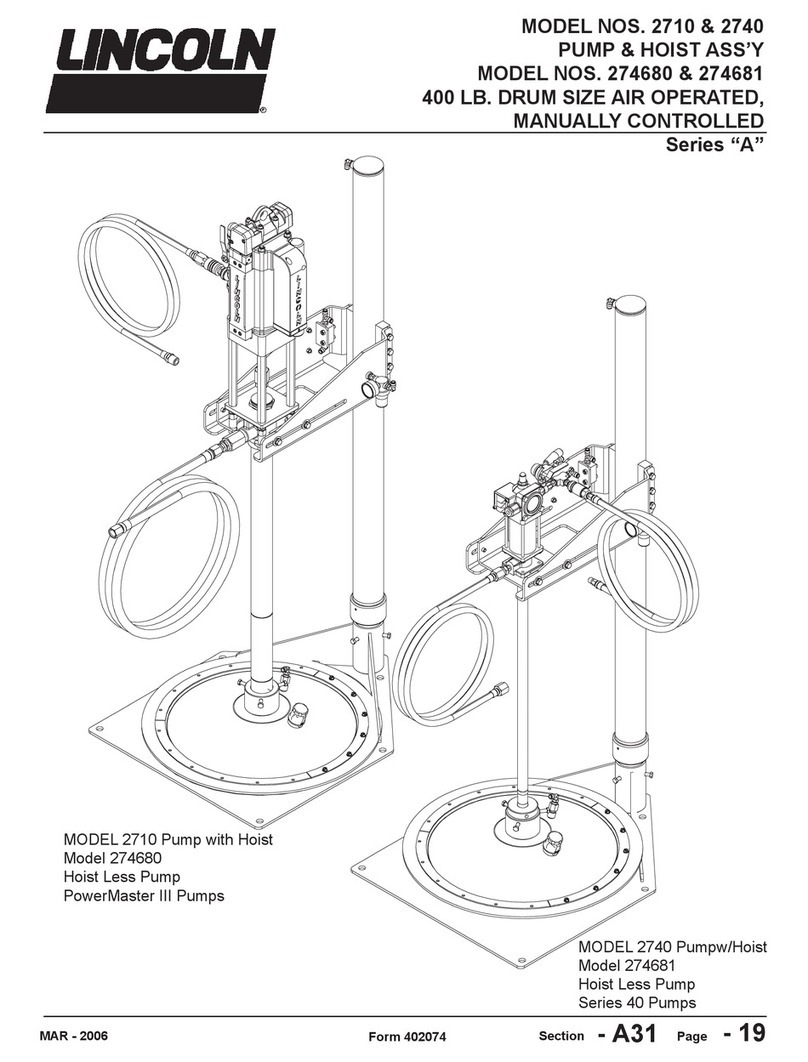

12 Assemble the truck assembly (29)

(† fig. 3, page 6). Leave the hex

screws, (24) and set screws, (26) loose

until a container drum is placed on the

truck. Install the casters, (28) into the

sockets on the bottom side of the truck

base. They should snap into place and

not fall out when the truck is lifted from

the floor.

13 Place the truck assembly on the floor.

Place a container drum containing the

lubricant to be dispensed onto the truck

base. Center the drum on the base and

adjust the clamp assemblies close

enough to the base of the drum so that

the set screws can be adjusted in to

secure the drum. They should also be far

enough away from the base of the drum,

so that the drum can be removed by

loosening the set screws (26) only. Tight-

en the hex screws (24) securely in four

places.

14 Place the assembled follower (17) into

the open drum, on top of the lubricant,

and push down on the follower until the

lubricant flows slightly into the center

opening of the follower.

15 Place the pump tube, assembled with

the drum cover, into the drum by sliding

the pump tube into the center hole in the

follower and sliding straight into the fol-

lower. The pump tube should slide all the

way into the drum until the drum cover

gasket rests on the top edge of the drum.

The follower (17) will remain on top of

the grease, and will move down with the

lubricant as it is consumed, wiping the

pail walls clean, and moving the lubricant

towards the pump inlet.

16 Secure the drum cover to the drum with

the three fillister head screws (11) by

tightening until the screws are snug

against the side of the drum.

17 Place the control valve grease coupler

through the control valve hanger (15) on

the side of the drum cover for convenient

storage. The hose may be coiled around

the drum as desired.

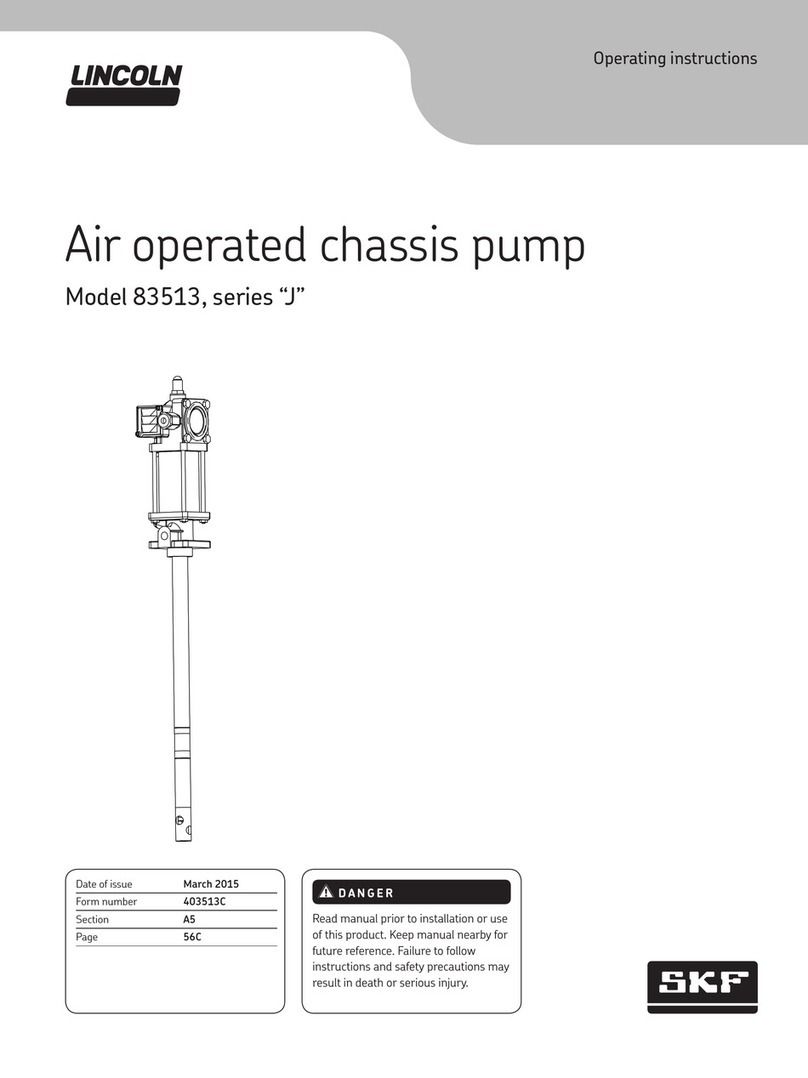

18 Follow the priming instructions as

detailed in the pump operation manual

(† section A5, page 6 series).

Model 9917-57

† fig. 1, page 3 of this manual.

1 Assemble the control valve hanger (15)

to the side of the drum cover (9) using

the two hex head screws (16) and hex

nuts (14) through the holes provided

in the cover.

2 Install the three fillister head screws (11)

into the side of the drum cover (9) as

shown. Leave the screws loose. They will

be used later to secure the drum cover

onto the drum.

3 Assemble the pump to the drum cover

with the four bolts (13) supplied, as

shown in the figure. Tighten securely.

4 Connect straight swivel (7) to pump out-

let. (Note that there are two different

threads on the swivel. The 1/4-18 NPT

pipe thread will be a course thread com-

pared with the other thread.) Make sure

to place the 1/4-18 NPT male end of the

swivel into the 1/4-18 NPT female outlet

on the pump body. Tighten securely.

5 Connect one end of the high pressure

hose (22) to the special (fine pitch) male

thread on the straight swivel (7) and

tighten securely.

6 Connect the remaining end of the high

pressure hose to the special male thread

on the universal swivel (6) and tighten

securely.

7 Connect the 1/4-18 NPT male thread

on the universal swivel (6) to the control

valve (1) and tighten securely.

8 Install the grease coupling and extension

tube into the outlet end of the control

valve (1) and tighten securely.

9 Install the air nipple (4) into the air inlet

of the pump and tighten securely.

10 Attach the air coupler (5) onto a suitable

3/8 in. inner diameter (minimum) air hose

and tighten securely. Do not apply air

pressure at this time.

11 Assemble the follower (17) per the

instructions in section K5, page 6 series.

12 Place the assembled follower (17) into

the open drum, on top of the lubricant,

and push down on the follower until the

lubricant flows slightly into the center

opening of the follower.

13 Place the pump tube, assembled with

the drum cover, into the drum by sliding

the pump tube into the center hole in the

follower and sliding straight into the fol-

lower. The pump tube should slide all the

way into the drum until the drum cover

gasket rests on the top edge of the drum.

The follower (17) will remain on top of

the grease, and will move down with the

lubricant as it is consumed, wiping the

pail walls clean, and moving the lubricant

towards the pump inlet.

14 Secure the drum cover to the drum with

the three fillister head screws (11) by

tightening until the screws are snug

against the side of the drum.

15 Place the control valve grease coupler

through the control valve hanger (15) on

the side of the drum cover for convenient

storage. The hose may be coiled around

the drum as desired.

Model 9946P

† fig. 1 page 3 of this manual.

1 Assemble the control valve hanger (15)

to the side of the drum cover (9) using

the two hex head screws (16) and hex

nuts (14) through the holes provided

in the cover.

2 Install the three fillister head screws (11)

into the side of the drum cover (9) as

shown. Leave the screws loose. They will

be used later to secure the drum cover

onto the drum.

3 Assemble the pump to the drum cover

with the four bolts (13) supplied, as

shown in the figure. Tighten securely.

4