LINK 2011-2016 Ford F250 Crew Cab Front Right p.2

WARNINGS

PLEASE REVIEW BEFORE STARTING THE INSTALLATION

Look through the entire manual to understand the installation process.

Watch the tutorial videos that are found on the tablet.

During the installation use the ‘BYPASS’ mode to move the LINK.

Do not use the pendant or ‘PENDANT’ mode until you have reset the home position.

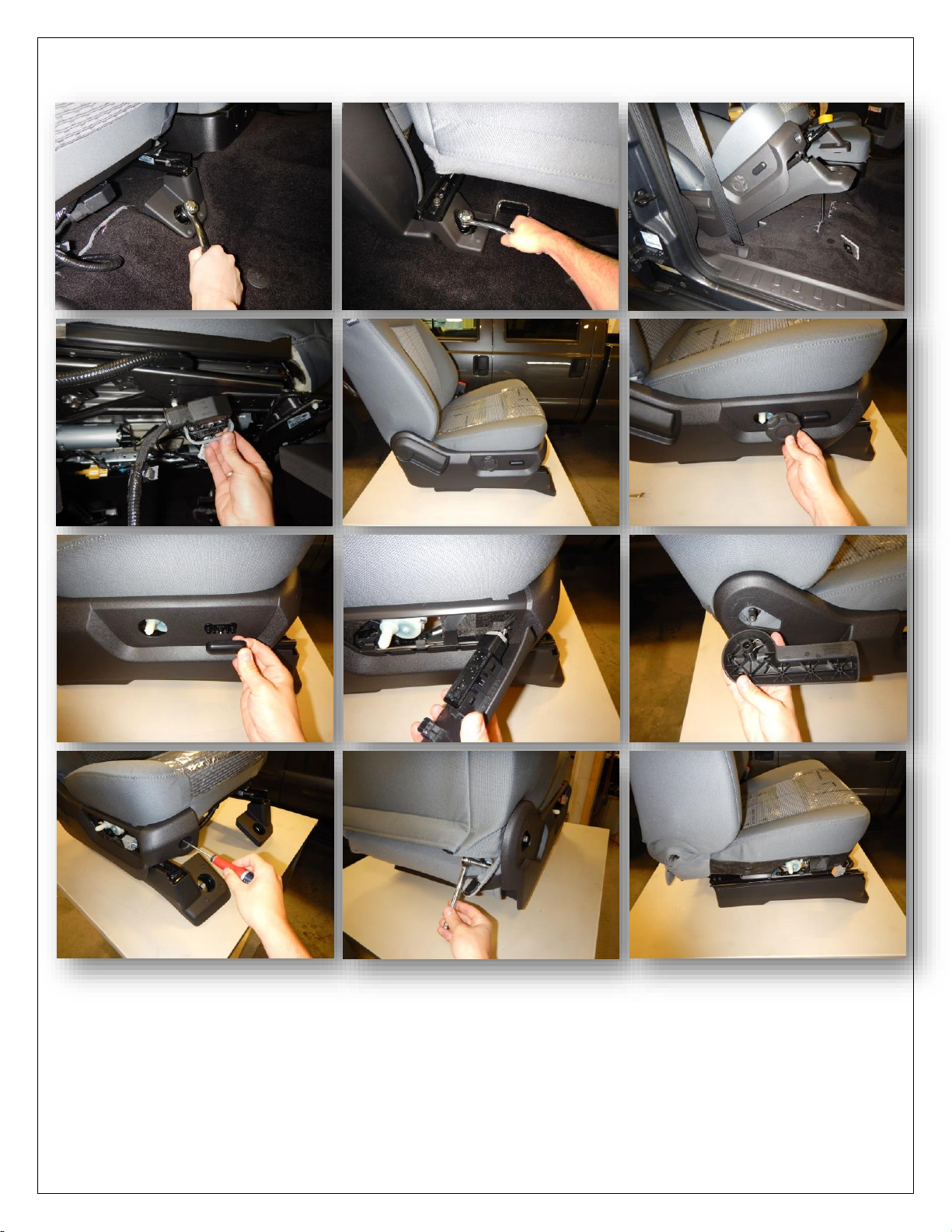

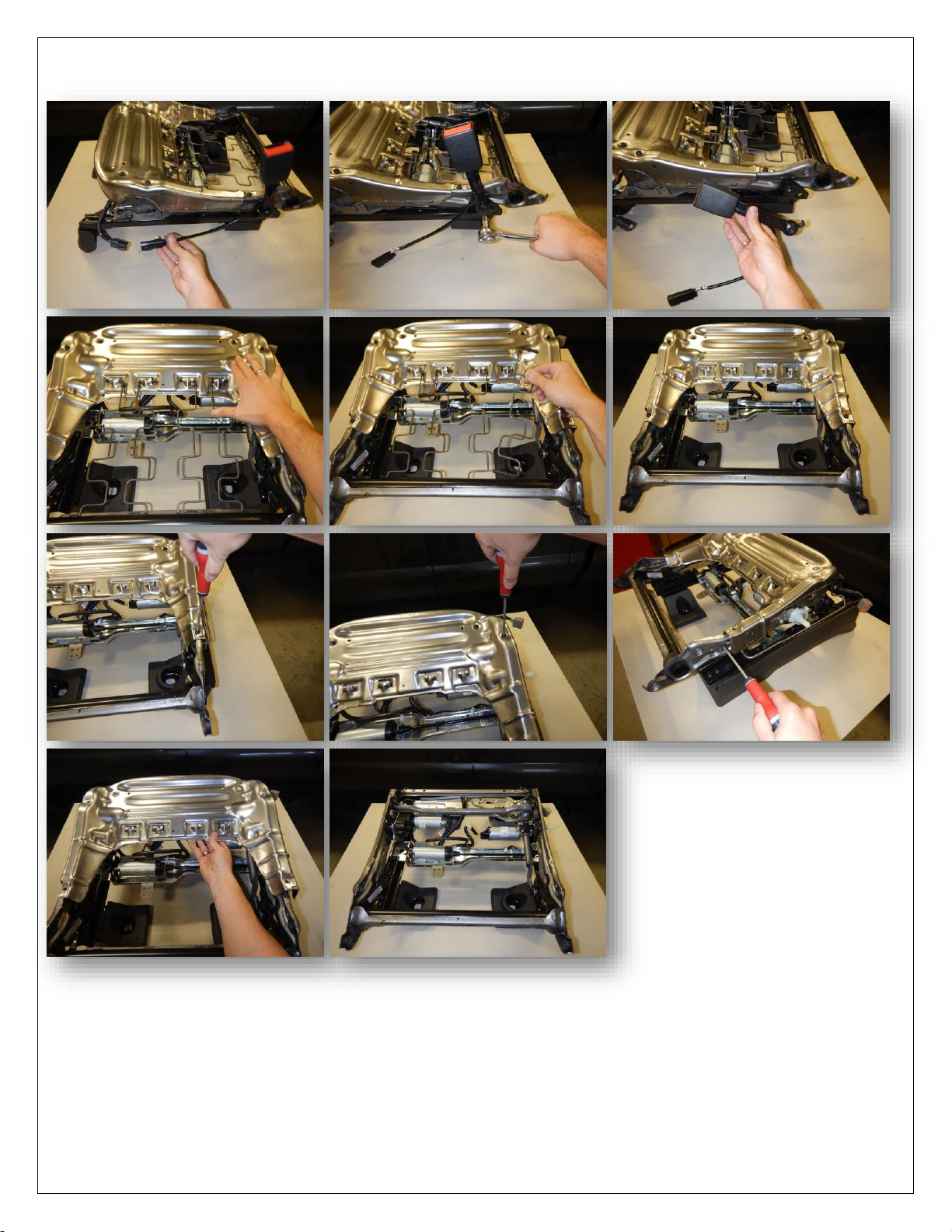

The LINK is designed to ALWAYS use the original seat. The biggest challenge this will present for the installer will

be extending the vehicle’s original seat wire harness, as this MUST be done. The general process does not vary, but

the exact steps will vary due to the trim level, the model and seat options from the vehicle manufacturer. Keeping

this in mind, we have made an effort to clearly describe the process required in this manual. However, it is possible

that the pictures in this manual do not match exactly the specific vehicle you are working on.

SEAT WIRING EXTENSION PROCESS

The wiring must be extended 80 inches. This extension is placed near the seat connectors that are under the seat.

The extension (80 inches) then passes under the LINK and loops around the back of the OEM seat –allowing the

seat and the LINK to travel in and out of the vehicle. Depending on the make, model and seat options, there are

components that must be disconnected, bypassed and/or relocated. On vehicle models with a seat position

memory function, the forward/backward, tilt and height adjustments as well as seat memory are replaced by the

LINK. However, the seat recline function is retained. (EXAMPLE: In the Ford F150, 2009-2014 model; the seat

height, tilt, forward and backward adjustment motors are disconnected and removed with the seat frame, but the

recline motor is retained. The control and memory box are relocated to the floor under the seat, next to the seat

connectors. The seat position sensor is also relocated to the floor under the seat. The wiring harness is then

extended from this point under the seat.)

PLEASE NOTE: If the ignition is turned on while extending a wire harness that includes airbags, this may cause the

airbag light to stay on following the installation.

ADAPT SOLUTIONS CANNOT BE HELD RESPONSIBLE FOR FAULTY WIRE EXTENSIONS.

Please use caution during the installation.

ANDROID TABLET –LINK I.T. SOFTWARE

If this is your first installation of a LINK, you will have also purchased an Android tablet that is required for the

installation and maintenance of the LINK product. This tablet will have the LINK IT software already installed.

We have prepared quick, easy and to the point tutorial videos imbedded into the software. Take a moment and

watch the video that shows all the features of the tablet. To do this, open the LINK IT app and tap on ‘INFO’.

Make sure your volume is turned up and tap on App-101. The video will start automatically.

REDUCED POWER MODE

A safeguard is integrated in the LINK system. Following any changes to the preset or sequence of the LINK, the

unit will enter a reduced power mode. This is to allow you to visually inspect the movements of the LINK to ensure

it is not damaging the vehicle or itself during its first cycle. On the tablet, a yellow bar will appear at the top of the

screen to indicate you are in reduced power mode. To exit, simply run the LINK a full cycle. NOTE:It is possible

that the LINK will stop during this cycle as power is reduced. Visually confirm nothing is impeding the movements

and then simply press the IN or OUT button again to continue the cycle. During the installation, if the 12V power is

removed and replaced at the same time as the 9V battery (LINK memory back up) is unplugged or fully drained,

the LINK will enter reduced power mode. Simply run a full cycle to exit. PLEASE NOTE: You will find an explanation

of this mode on a YELLOW tag attached to the hand pendant. Please explain the functions of the reduced power

mode to the LINK user (your client).

For technical support call 866.641.0419 or email tech@adaptsolutions.com

Please have the serial number of the unit on hand before placing your call.