AIR LINK 60k Suspension –Installation Manual Rev.00 (11/20/2019)

Proprietary and Confidential 3

Table of Contents:

SECTION 1: COMPONENT TERMINOLOGY ................................................................................... 5

SECTION 2: INTRODUCTION......................................................................................................... 6

Description.................................................................................................................................. 6

Safety Notice............................................................................................................................... 6

SECTION 3: ASSEMBLY ................................................................................................................. 7

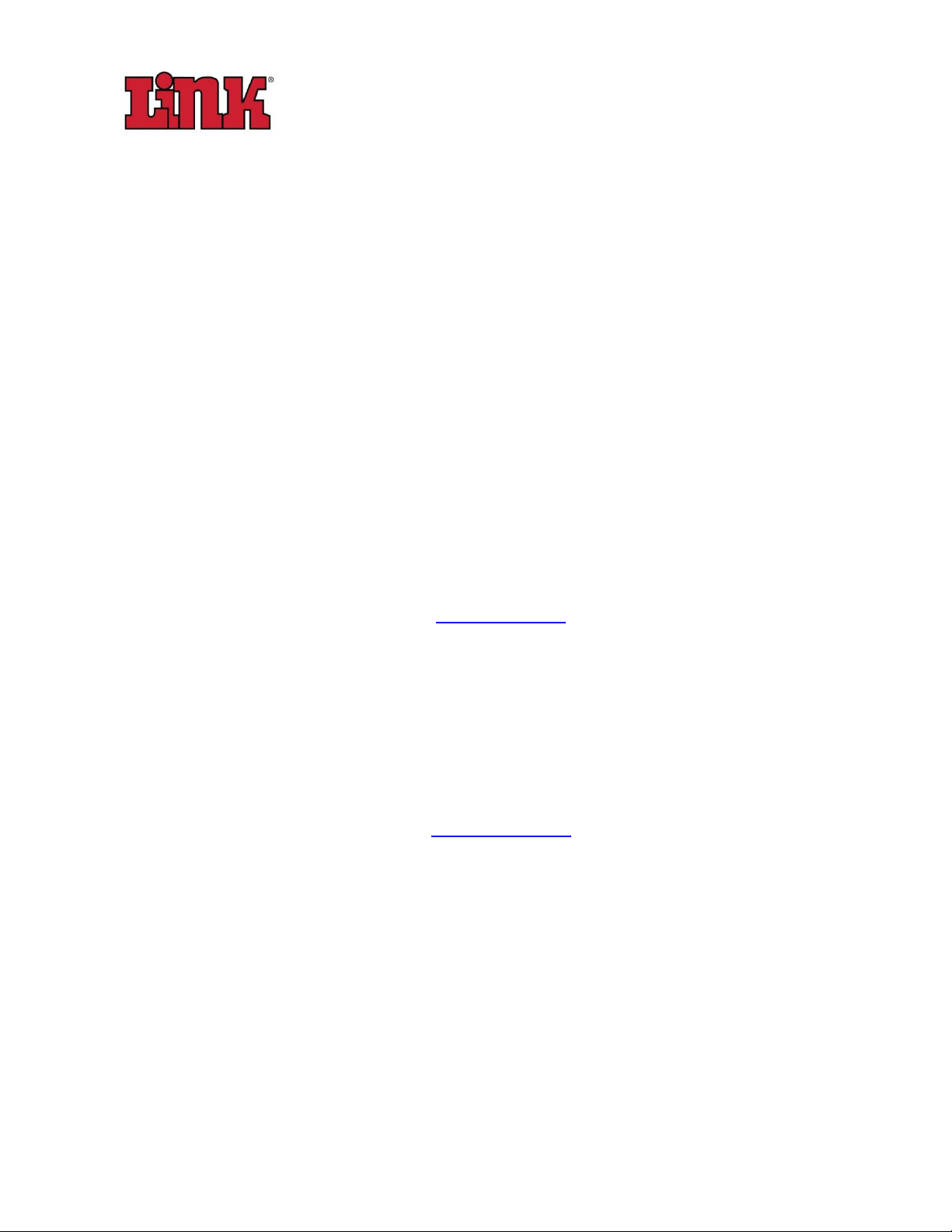

Assemble the Axle to the Walking Beams (2-1/2ӯ Adapter Bushing)...................................... 7

Required Components ............................................................................................................ 7

Required Tools ........................................................................................................................ 8

Procedure................................................................................................................................ 8

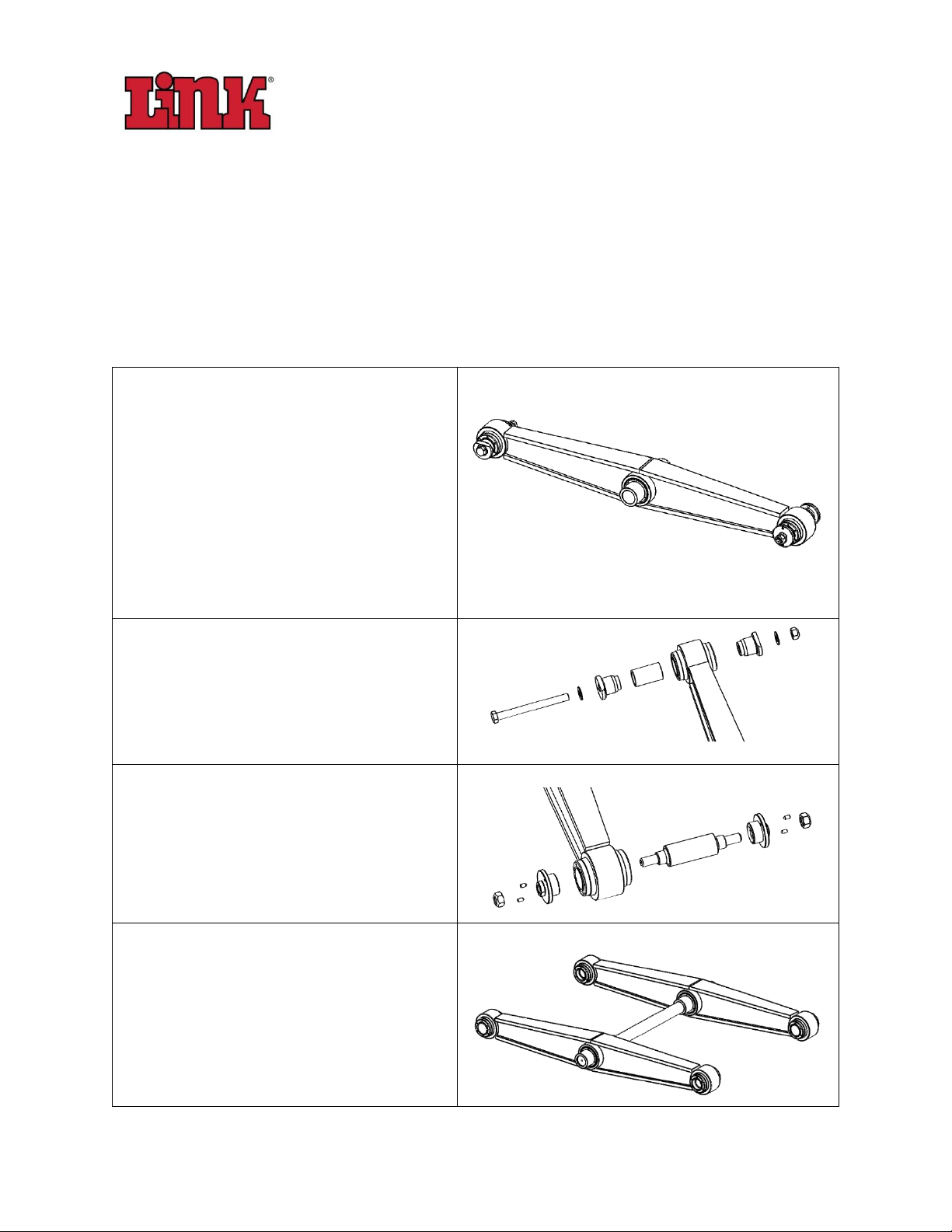

Assemble the Axle to the Walking Beams (3ӯ Adapter Bushing)........................................... 12

Required Components .......................................................................................................... 12

Required Tools ...................................................................................................................... 12

Procedure.............................................................................................................................. 13

Install Frame Mounted Components........................................................................................ 17

Required Components .......................................................................................................... 17

Required Tools ...................................................................................................................... 17

Procedure.............................................................................................................................. 18

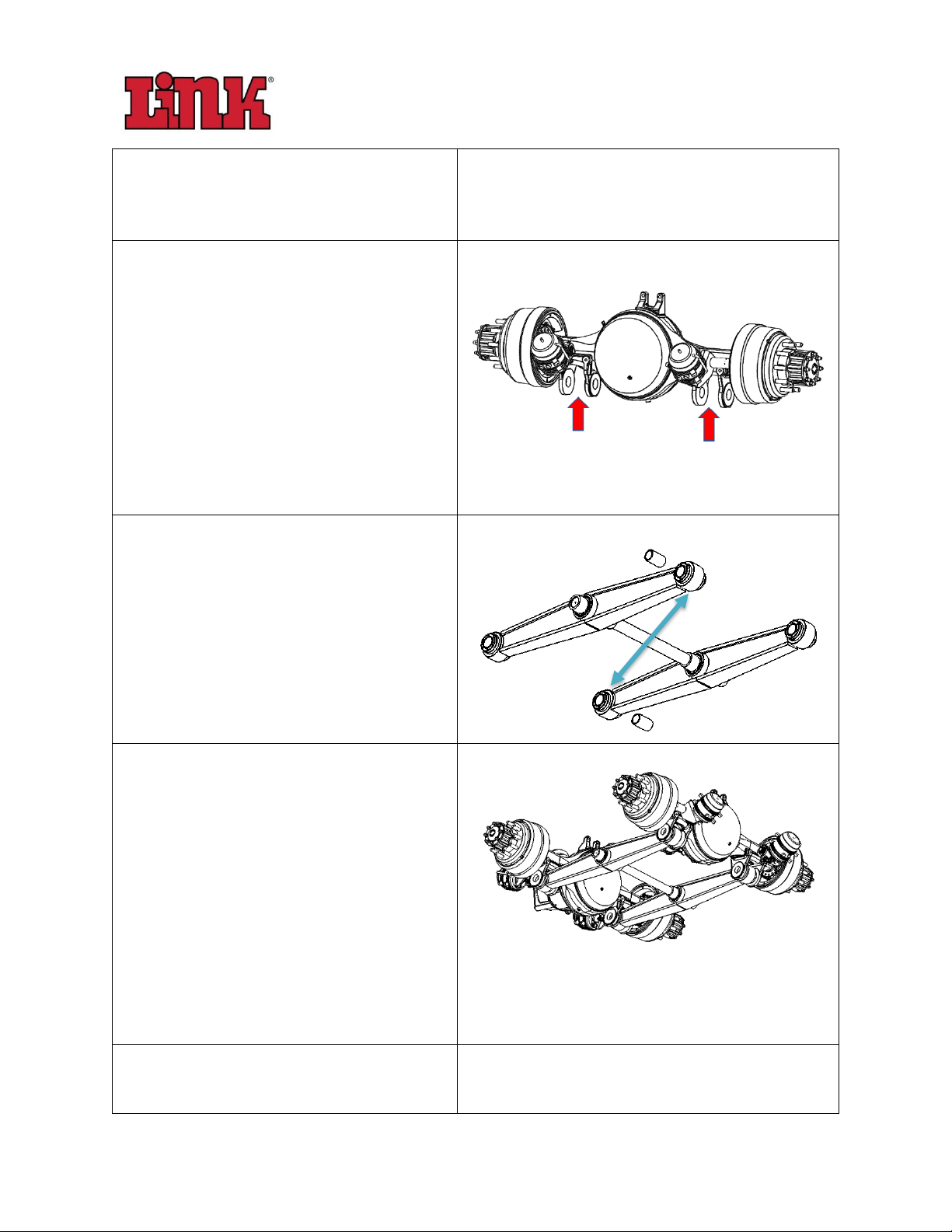

Install the Trailing Arm.............................................................................................................. 20

Required Components .......................................................................................................... 20

Required Tools ...................................................................................................................... 20

Procedure.............................................................................................................................. 20

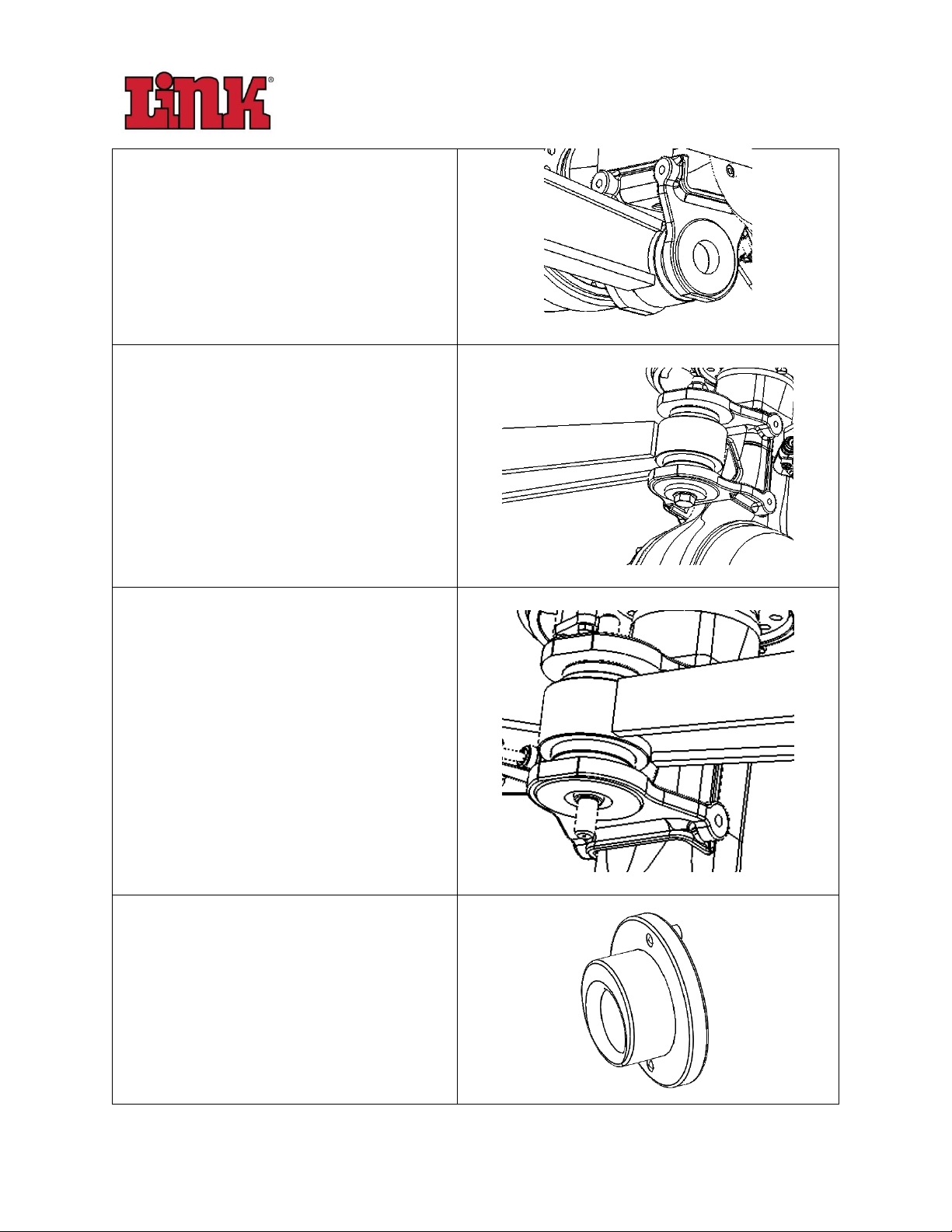

Install Air Spring........................................................................................................................ 23

Required Components .......................................................................................................... 23

Required Tools ...................................................................................................................... 23

Procedure.............................................................................................................................. 24

Install the Shock........................................................................................................................ 27

Required Components .......................................................................................................... 27

Required Tools ...................................................................................................................... 27

Procedure.............................................................................................................................. 28

Install Restraint Strap................................................................................................................ 30