logitrans WSP 2200 User manual

Other logitrans Forklift manuals

logitrans

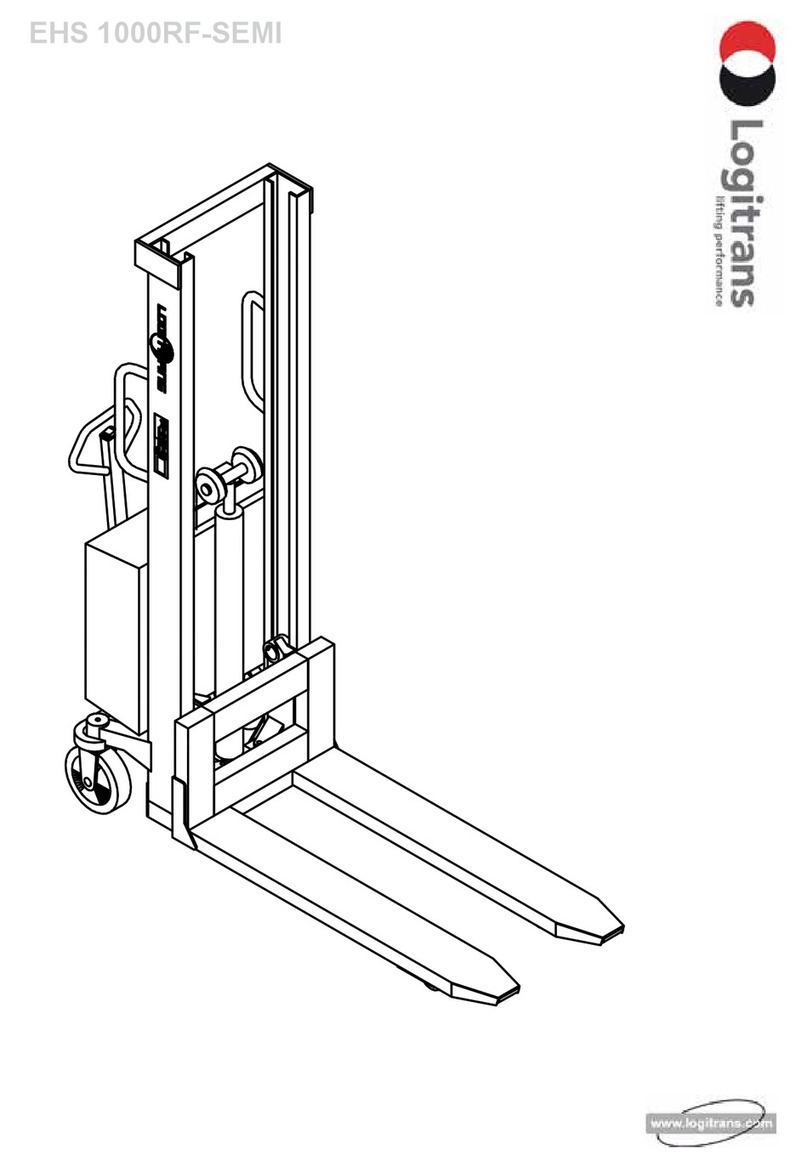

logitrans HS 1000RF-SEMI User manual

logitrans

logitrans LOGIFLEX ELF User manual

logitrans

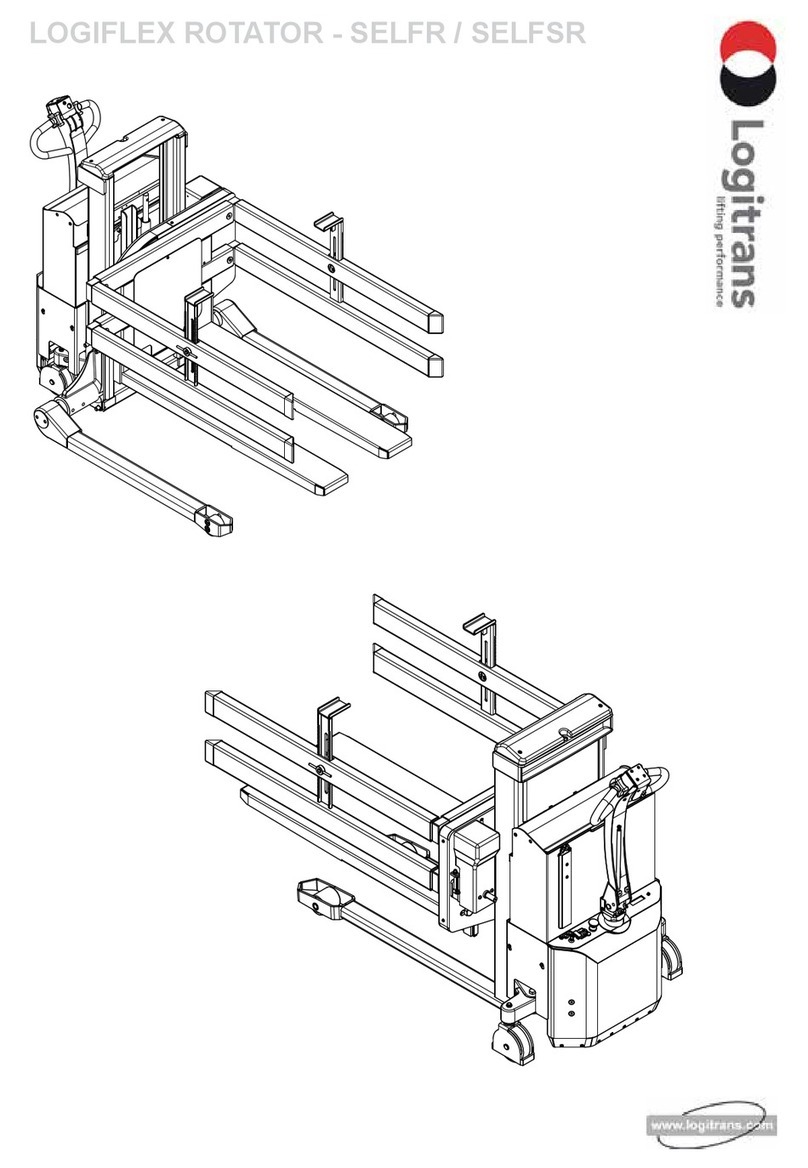

logitrans ROTATOR SELFR User manual

logitrans

logitrans Logiflex Owner's manual

logitrans

logitrans ROTATOR ELFR User manual

logitrans

logitrans LOGIFLEX SELF MAXI User manual

logitrans

logitrans EHS Stainless 1000/1400 User manual

logitrans

logitrans SGL/Panther User manual

logitrans

logitrans Level Control LC4 User manual

logitrans

logitrans LOGIFLEX ELFR User manual

logitrans

logitrans ELF 1001/1200 User manual

logitrans

logitrans Logiflex ELF1201 User manual

logitrans

logitrans LOGIFLEX SELF1003 User manual

logitrans

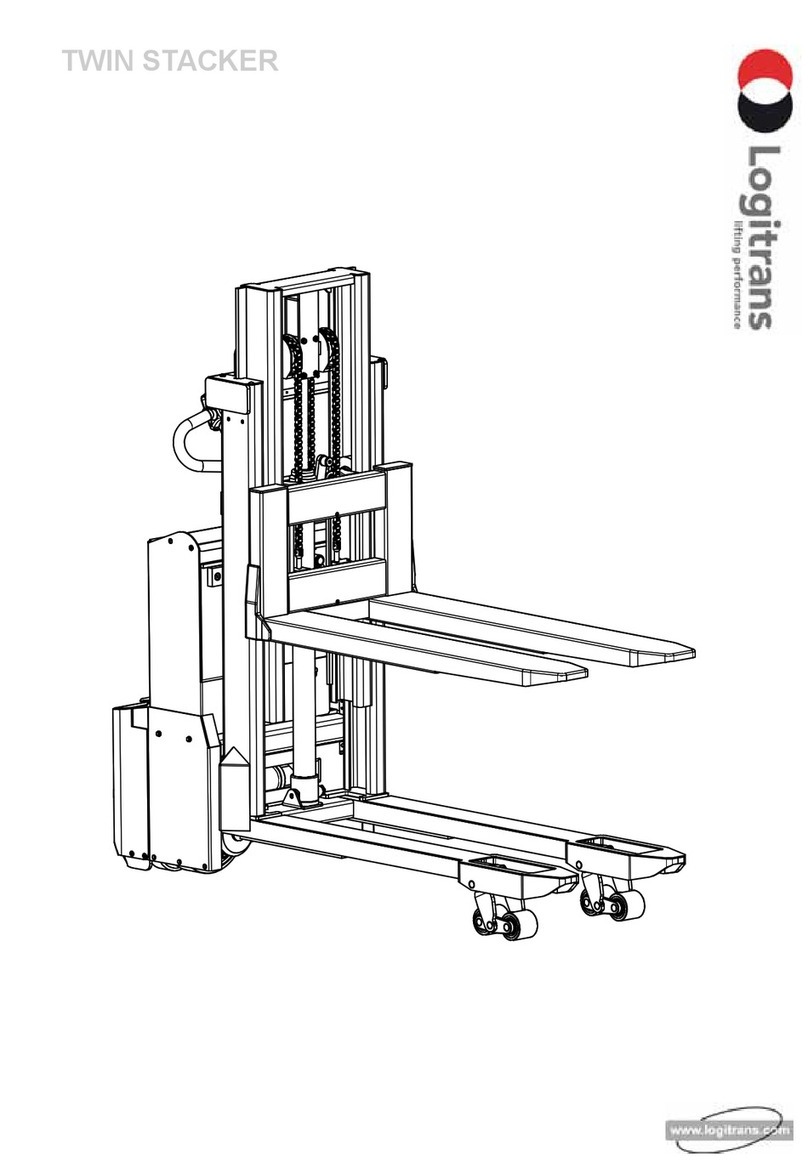

logitrans Twin Stacker User manual

logitrans

logitrans LOGIFLEX ELF Owner's manual

logitrans

logitrans EHS 1000RF-SEMI User manual

logitrans

logitrans LOGIFLEX SELF 1001 User manual

logitrans

logitrans PANTHER MAXI AC User manual

logitrans

logitrans EHL 1004 Guide

logitrans

logitrans LOGIFLEX SELFR Series User manual