www.longer3d.com info@longer3d.com

Catalog

A. Product information........................................................................................................................3

(1) Model parameter...................................................................................................................3

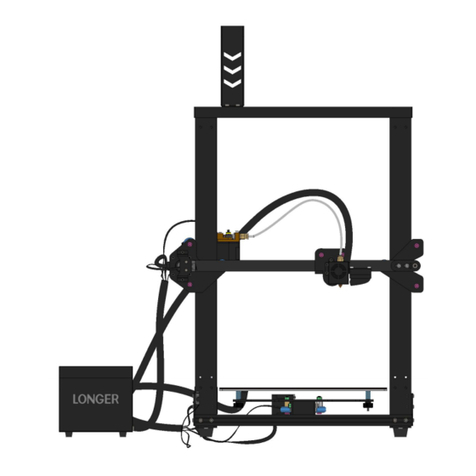

(2) Machine introduction............................................................................................................ 4

(3) Nozzle module exploded view...............................................................................................4

(4) Machine assembly................................................................................................................. 5

1. Gantry installation...........................................................................................................5

2. X-axis installation.............................................................................................................6

3. Mounting the x-axis beam.............................................................................................. 9

4. Install the gantry upper beam.........................................................................................9

5. Mounting screw...............................................................................................................9

6.Install Teflon tube...........................................................................................................10

7.Install the z-axis limit switch.......................................................................................... 11

8.Mounting aluminum substrate...................................................................................... 11

9.Wiring............................................................................................................................. 12

10. Screen wiring...............................................................................................................12

11.Mounting rack.............................................................................................................. 13

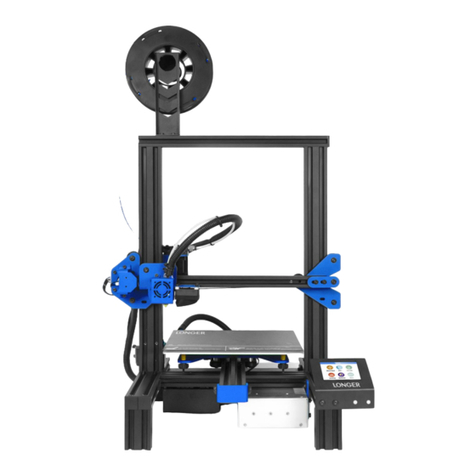

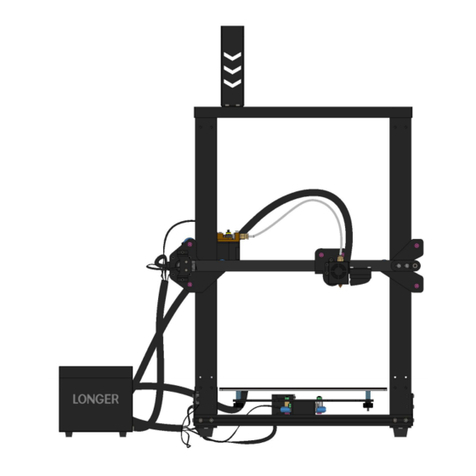

12 .Assembly completed...................................................................................................13

(5)Power regulation...........................................................................................................14

(6)leveling method...............................................................................................................15

B.Machine operation....................................................................................................................16

(1)Machine control interface description........................................................................... 16

(2)Home interface................................................................................................................18

(3)Move interface................................................................................................................ 19

(4)Tune interface..................................................................................................................20

(5)Utilities interface.............................................................................................................22

(6)Print interface..................................................................................................................25

C.Cura installation and operation software................................................................................. 26

(1)Slice software offline printing instructions.....................................................................29

(2)Software parameter setting............................................................................................ 32

D.Operation for online printing....................................................................................................35

E.Resume printing and filament run-out detection function......................................................38

(1)Power failure................................................................................................................... 38

(2)Broken material detection.............................................................................................. 39

F.FAQ manual............................................................................................................................... 40

Question1: How to update the firmware?...........................................................................40

Question 2:What if the filament does not discharge from the machine?.................... 41

Question 3:.............................................................................................................................. 42

Question 4: What should I do if I cannot resume printing after power shutdown?..... 43

Question 5:.............................................................................................................................. 43

Question 6:............................................................................................................................... 44