7. ADJUSTMENT PROCEDURE

7. 1. MANUAL OPERATION

The MSPxC can be manually controlled regardless of the

communications status. Turn the SW5-1 ON to enable the

manual operation mode. The SW8 and SW7 are used for

control.

Table 2. SW5 setting, manual operation

SW5 OFF ON

1

Control via com-

munications

Manual operation

2 Invalid 0% manual control command

3 Invalid 100% manual control command

4 Unused

Turning both SW5-2 and -3 is invalid. The actuator operation

stops.

SW8: The stem moved toward 0% position while pressing

this switch.

SW7: The stem moved toward 100% position while pressing

this switch.

7. 1. 1. GENERAL PROCEDURE

After installing the valve and actuator, go to adjustments in

order of Zero, Span, and the seal-spring.

7.1.2. ZERO & SPAN

1) Zero Adjustment: Turn the power supply on and set the

SW5-1 and -2 ON (OFF for the others on the SW5). This

turns the actuator into the manual operation mode and

automatically controls the stem toward the 0% position.

Once the stem reaches the position, adjust either the ac-

tuator with the Zero potentiometer or the mechanical po-

sition of the valve stem connection so that the actuator’s

extended position (valve’s retracted position) is adequate.

If extra sealing pressure by the seal-spring is required,

push in the actuator stem referring to Table 3.

2) Span Adjustment: Turn the power supply on and set the

SW5-1 and -3 ON (OFF for the others on the SW5). This

turns the actuator into the manual operation mode and

automatically controls the stem toward the 100% posi-

tion.

Once the stem reaches the position, adjust either the ac-

tuator with the Span potentiometer or the mechanical

position of the valve stem connection so that the actua-

tor’s retracted position (valve’s extended position) is ad-

equate.

For three-way valves, the sealing pressure can be adjust-

ed to be applied in the direction where the output stem

is fully retracted (not available for the MSP4C). Adjust-

ment procedure is the same for Zero.

3) With 0% input again, check that the Mini-Top is at the

fully extended position. If the position is shifted, go

through the above procedure again.

Note 1: There is only minimal effect of span adjustment to

zero point, thus the stem position shifts very little

at the extended side when the span potentiometer is

turned.

Note 2: With the stroke narrower, hunting (the motor repeats

changing direction) can happen more often. Adjust

Deadband in such cases.

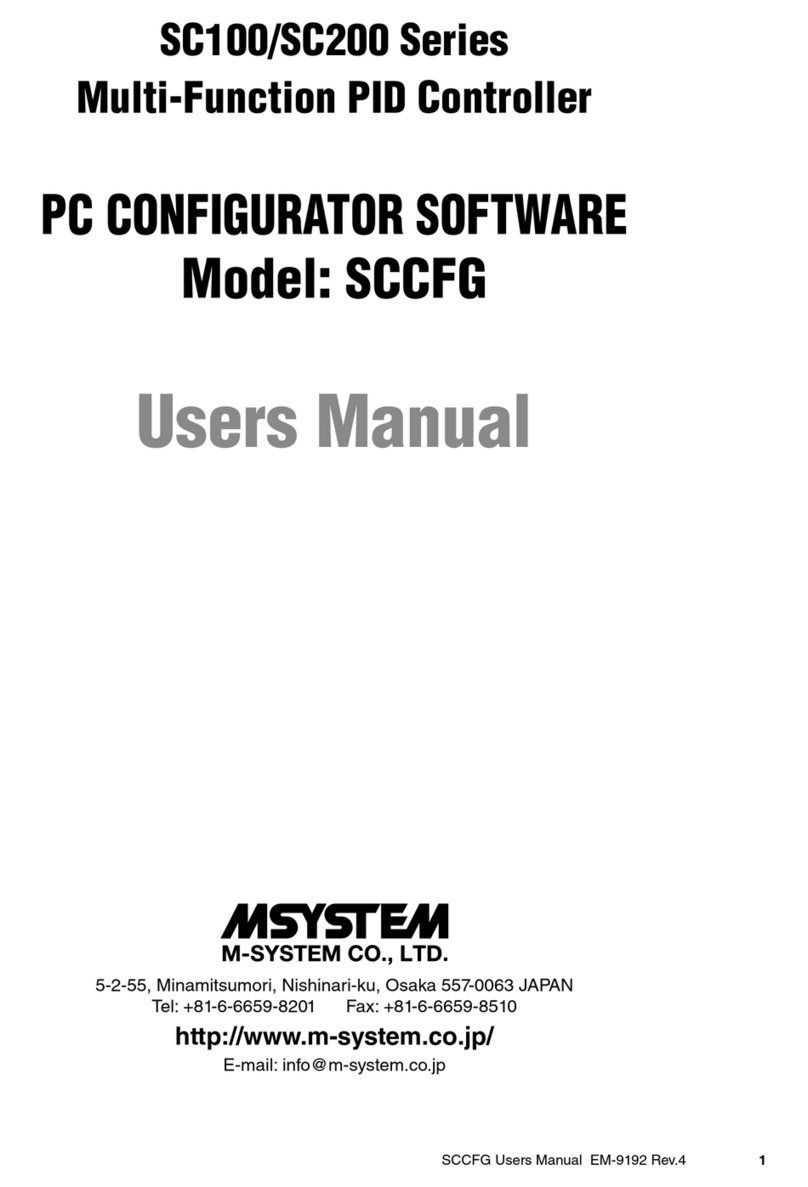

Output Stem

Seal Spring Division

Figure 10. Seal-spring

Table 3. Seal-spring pressure

MODEL

SPRING

CONTRACTION

(mm)

CONTACT*

PRESSURE

(N / lbs)

SEALING

PRESSURE

(N / lbs)

MSP4C-x3 0.5 147/33 98/22

MSP4C-x4 1.0 300/67 250/56

MSP4C-x7 1.0 686/154 294/66

MSP5C-x3 0.5 150/34 110/25

MSP5C-x4 1.0 294/66 216/49

MSP5C-x7 1.0 686/154 294/66

MSP6C-x3 1.0 588/132 441/99

MSP6C-x4 1.0 1170/263 882/198

MSP6C-x6 1.5 2350/529 1170/263

* The minimum pressure required to contract the spring.

Note: Graduations by 1 millimeter increments are marked

on the stem. For example, with MSP4C-x7, the sealing

pressure reaches approx. 490 N at 0.5 mm, 686 N at 1

mm.

7.1.3. DEADBAND

‘Deadband’ is provided in 0.2% increments from 0.1%, 0.3%,

0.5%, .... with the fractions dropped.

SW4 DEADBAND (%)

0 0.1

1 0.3

2 0.5

3 0.7

4 0.9

5 1.1

6 1.3

7 1.5

8 1.7

9 1.9

-0.3% -0.2% -0.1% TARGET +0.1% +0.2% +0.3%

0.1%

0.3%

0.5%

Figure 11. Deadband

7.1.4. RESTART LIMITING TIME

Set the restart limiting time as follows:

SW6-1 SW6-2

RESTART LIMITING TIME (sec.)

OFF OFF 0

ON OFF 1.5

OFF ON 5

ON ON 10

MSP4C / MSP5C / MSP6C

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4862 Rev.1 P. 6 / 9