EM-4887 P. 1 / 17

INSTRUCTION MANUAL

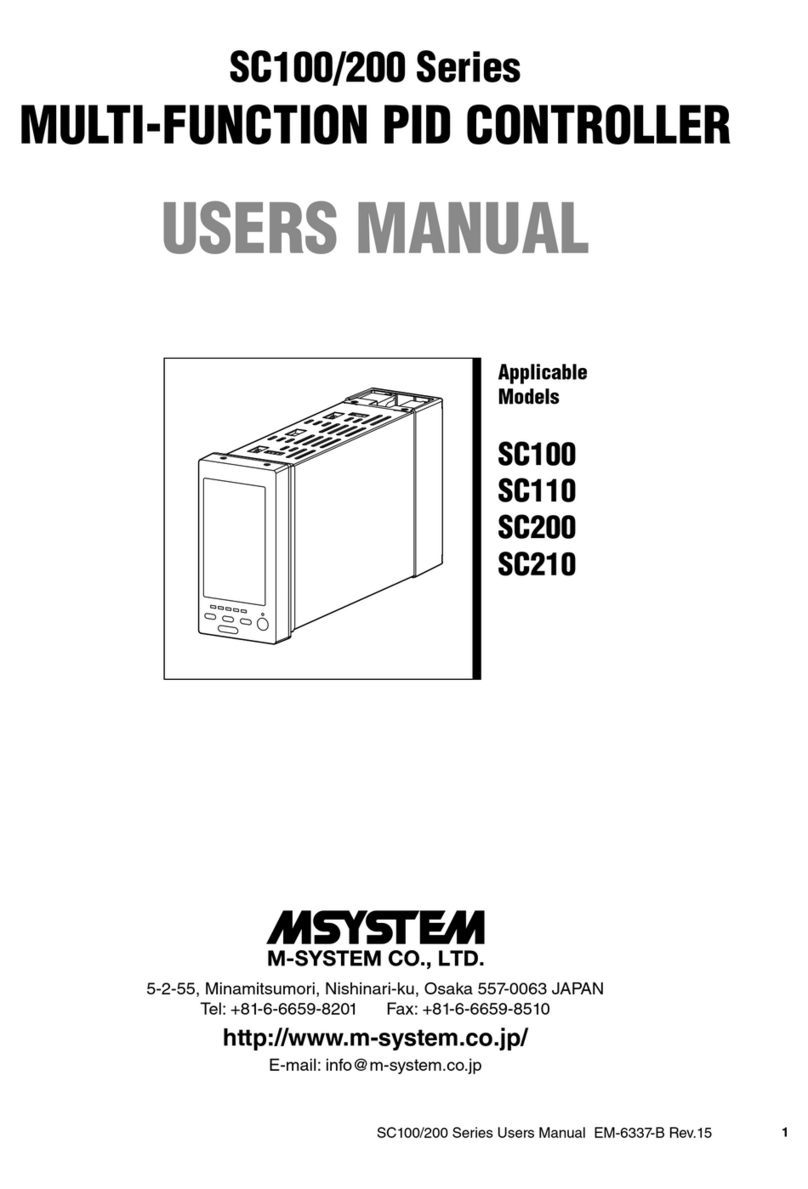

STEP-TOP ELECTRONIC ACTUATOR

(Linear type with Auto-setup function; Modbus communication)

MODEL MSP10

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Step-Top Electronic Actuator unit......................................(1)

The Step-Top Electronic Actuator is not provided with a

yoke or other components required for mounting the unit to

a valve. They are to be provided by the user.

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■SAFETY PRECAUTIONS

Before use, please read all the following precautions

carefully to ensure the safety. These safety precautions,

classified into “WARNING” and “CAUTION” according to

the degree of damage that may be caused by improper use

of the product, are imperative to prevent an accident. Af-

ter reading, be sure to keep this manual always in a visible

and accessible place for the user.

WARNING Suggesting that failure to observe the pre-

cautions could result in death or serious personal injury.

CAUTION Suggesting that failure to observe the pre-

cautions could result in personal injury or damage to the

property.

WARNING

Remove power supply to the actuator before wiring to the

unit. It could cause electric shock.

Do not disassemble or modify the unit in any way.

It could cause electric shock, burn, or injury.

DO NOT step onto the actuator unit.

DO NOT rest a heavy object on or against the unit.

It could cause personal injury.

When installing the actuator unit outdoor or where it

is exposed to rain or water drops, adequate precautions

must be taken for preventing water from entering inside

through wiring conduits. It could cause electric shock.

CAUTION

DO NOT remove the cover of the actuator. It may cause

electric shock or injury.

The adjusters which are paint-sealed are for factory use

only and should be changed only by qualified M-System

personnel. Otherwise it could cause breakdown.

M-System is not liable for any malfunction or inconven-

ience caused by unauthorized changes made by the user.

■INSTRUCTION MANUAL

This manual describes necessary points of caution for han-

dling this product and specifically for installation, wiring,

hardware setting, and basic maintenance of the product.

This unit is factory-adjusted and calibrated according to the

Ordering Information Sheet.

When the user needs to change settings, please also refer to

the Section B of Operation Manual (EM-9255) for the Pro-

gramming Unit (Model: PU-2x).

POINTS OF CAUTION

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

24V DC: 24V rating ±10%, approx. 1 A

■HUNTING

• Hunting is a condition in which the output stem is os-

cillated repeatedly and persistently without settling at a

single position.

• The actuator unit must operate at an average duty cycle

of 50% (approx. 13 strokes per minute) or less.

■GENERAL PRECAUTIONS

• Remove the power supply to the actuator before wiring

the unit.

• DO NOT install signal wires and power supply wires to-

gether in one duct because it may cause a malfunction

due to induction noises. Alternatively, use shielded cables

for the input signal wires to prevent interference from

such noises.

• If input signals are to be turned on/off with power sup-

plied to the actuator, be sure to specify the output stem

operation for when abnormally low input is detected.

• DO NOT loosen the screws fixing the potentiometer in-

side the unit.

■INSTALLATION

• Indoor, or outdoor where the unit is NOT exposed to di-

rect sunlight.

• Operating temperature -15 to +66°C (5 to 150.8°F)

• Operating humidity 30 to 90% RH (non-condensing)

• The unit is not designed to withstand all vibrations.

M-System does not guarantee long-term use of the unit

even with small vibrations. Please use the unit only after

evaluating in an actual installation environment. Par-

ticularly, avoid using under the condition where valve

cavitation or water hammer is likely to occur.

• Install the unit where it can be reached for maintenance

and inspection. Be sure to allow at least 20 cm (7.9 inch-

es) clearance above the unit and around the terminal box.

• Keep away from hazardous atmosphere such as explosive

or corrosive gases.

056 222 38 18 mailbox@sentronic.com www.sentronic.com

SENTRONIC AG