10JT

P. 4 / 4 EM-0863 Rev.4

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System'ssoleliability,andpurchaser'sexclusiveremedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System

Co.,

Ltd.,

5-2-55,

Minamitsumori,

Nishinari-ku,

Osaka

557-0063

JAPAN,

Phone:

(06)

6659-8201,

Fax:

(06)

6659-8510,

E-mail:

[email protected]MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the "ADJUST-

MENT PROCEDURE" explained earlier.

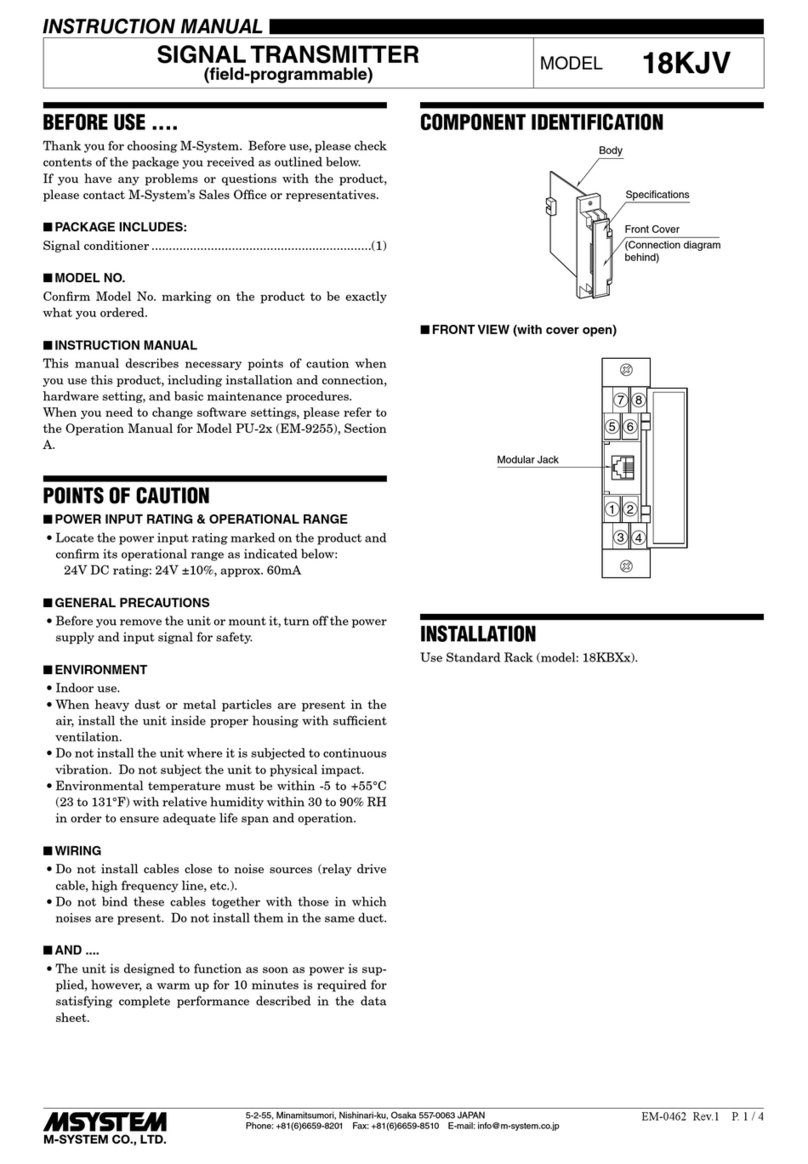

[GROUP 01]

ITEM INPUT DATA EXAMPLE (DEFAULT) CONTENTS

01 S 0, 1 MTSW : MON MODE Modification code

0 : Data indication only.

1 : All parameters are modifiable.

02 P Alphanumeric TG : XXXXXXXXXX Tag name entry (10 characters max.)

03 P Number (%) OUTPER XXX.XX Output status monitor (%) & simulation output

04 D No input OUTTMP XXXX.XX Output temperature monitor (unit: ITEM 21)

05 D No input INPPER XXX.XX Input status monitor (%)

06 D No input INPVAL XXX.XX Input status monitor in mV

07 D No input CJMTMP XXX.XX Cold junction compensation temperature (°C)

10 P TYPE OF THERMOCOUPLE

1Tc-1: (PR) (PR)

2Tc-2: K (CA) K (CA)

3Tc-3: E (CRC) E (CRC)

4Tc-4: J (IC) J (IC)

5Tc-5: T (CC) T (CC)

6Tc-6: B (RH) B (RH)

7Tc-7: R R

8Tc-8: S S

9Tc-9: WRe 5-26 WRe 5-26

0Tc-0: N N

14 P Actual value SCLLOW XXXXXX Input range scaling 0% value (unit: ITEM 21)

15 P Actual value SCLHIG XXXXXX Input range scaling 100% value (unit: ITEM 21)

19 P Percentage FINZER Fine zero adjustment

Initial status shows actual bias (%).

When data is entered, output (%) is shown.

20 P Percentage FINSPN Fine span adjustment

Initial status shows actual gain (%).

When data is entered, output (%) is shown.

21 P TEMPERATURE UNIT

0TMPSCL: [°C] °CProgram ITEM 21 first before ITEM 14 when °F or K

1TMPSCL: [°F] °Fcalibration is needed. This procedure is necessary whenever

2TMPSCL: [K] K thermocouple type is changed.

Modification Code

D: No modification (writing) possible. Used only for monitoring (reading).

S: Modifiable at any time.

P: Modifiable only when the MAINTENANCE SWITCH is in the “PRG” mode.

PROGRAMMABLE ITEMS

The following items can be monitored and programmed. For detailed explanations, please refer to the Operation Manual for

Model PU-2❑(EM-9255), Section A.

MDF.

CODE