VOS2T-R

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-4766 Rev.6 P. 3 / 4

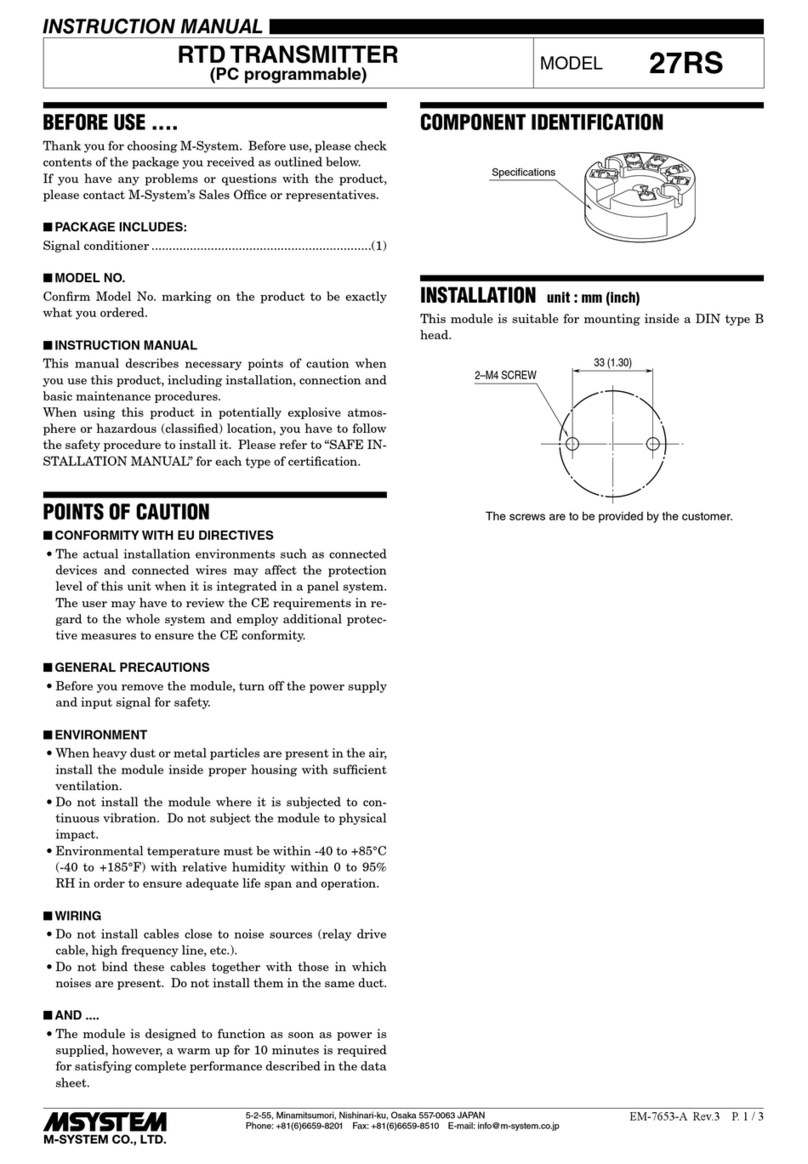

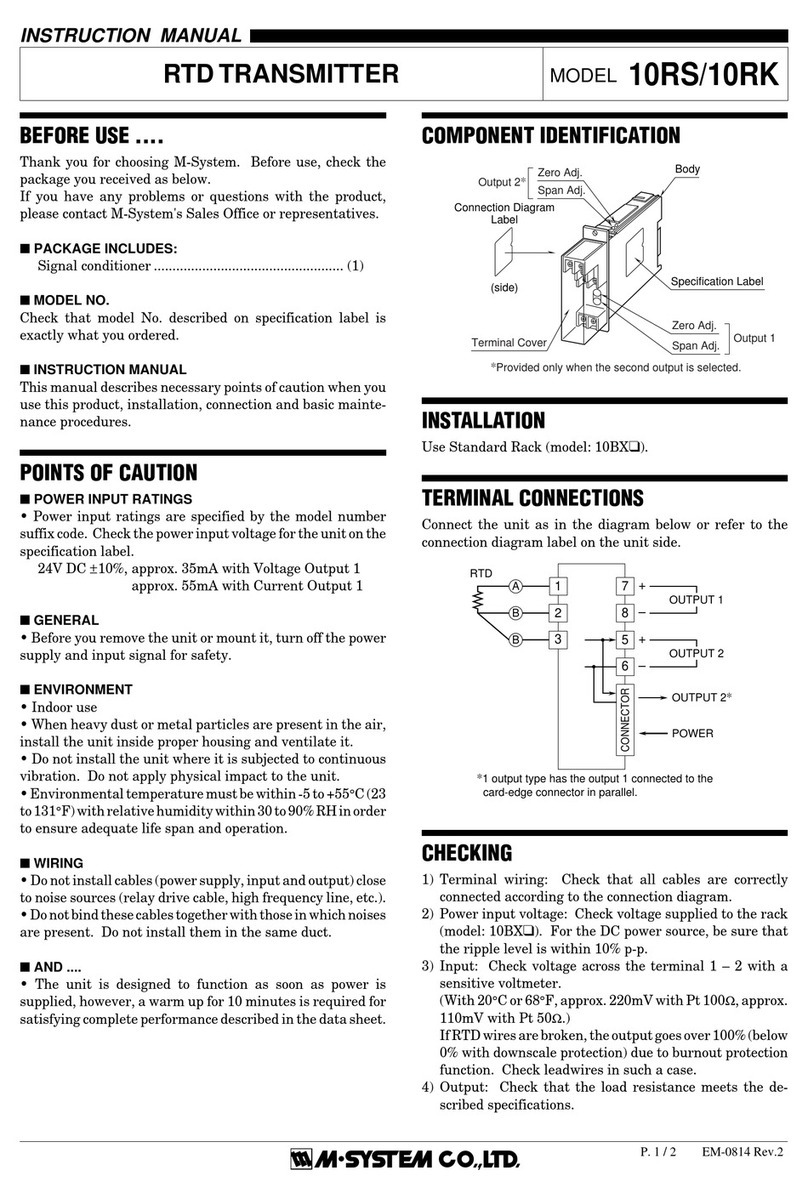

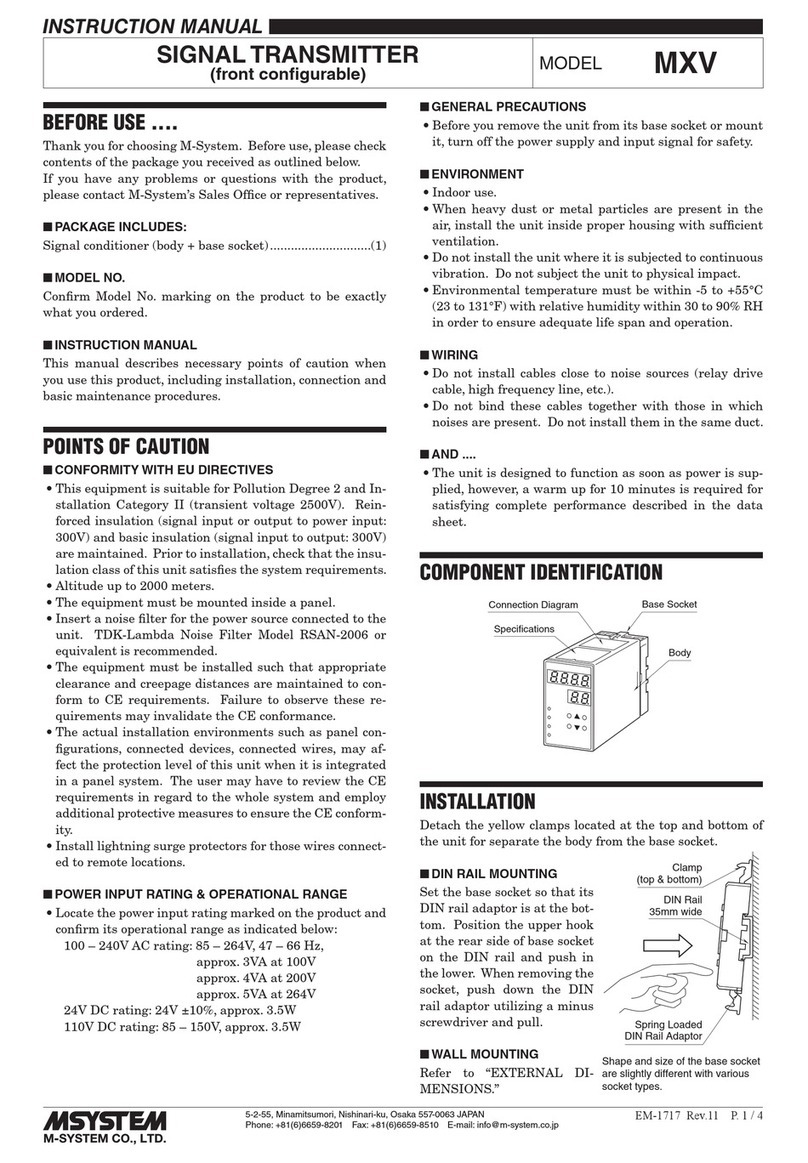

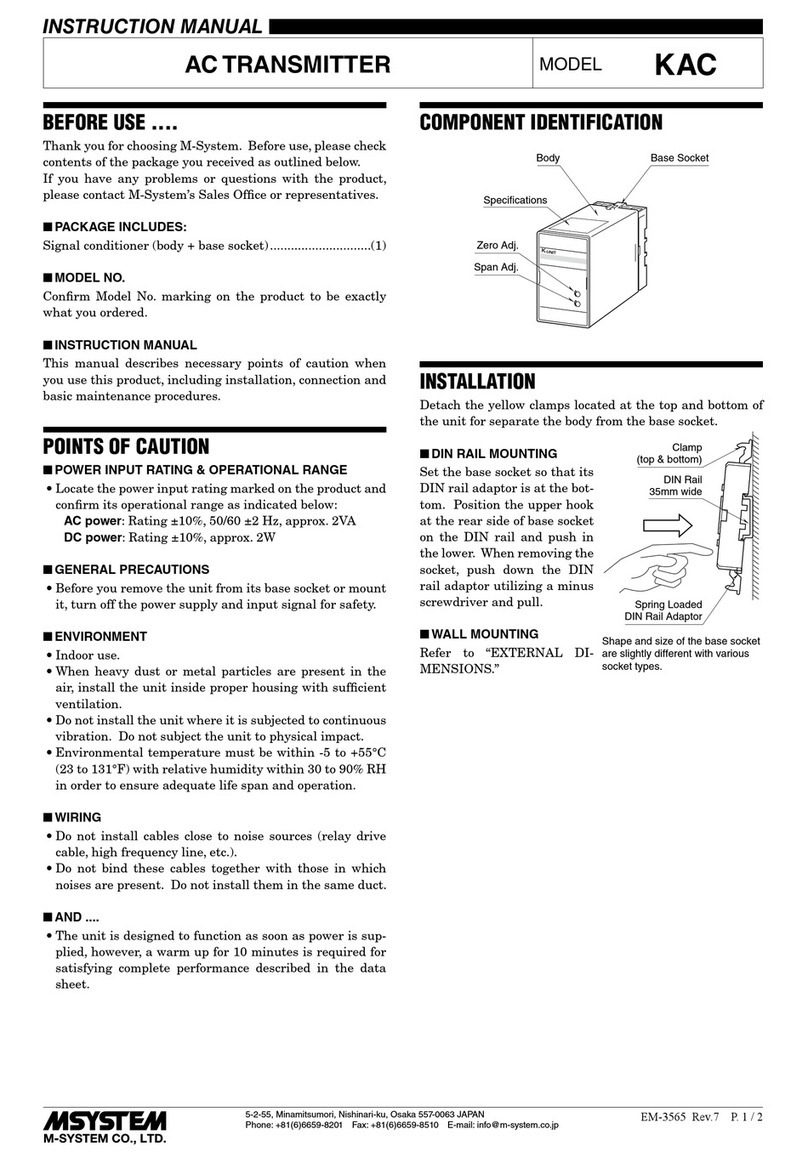

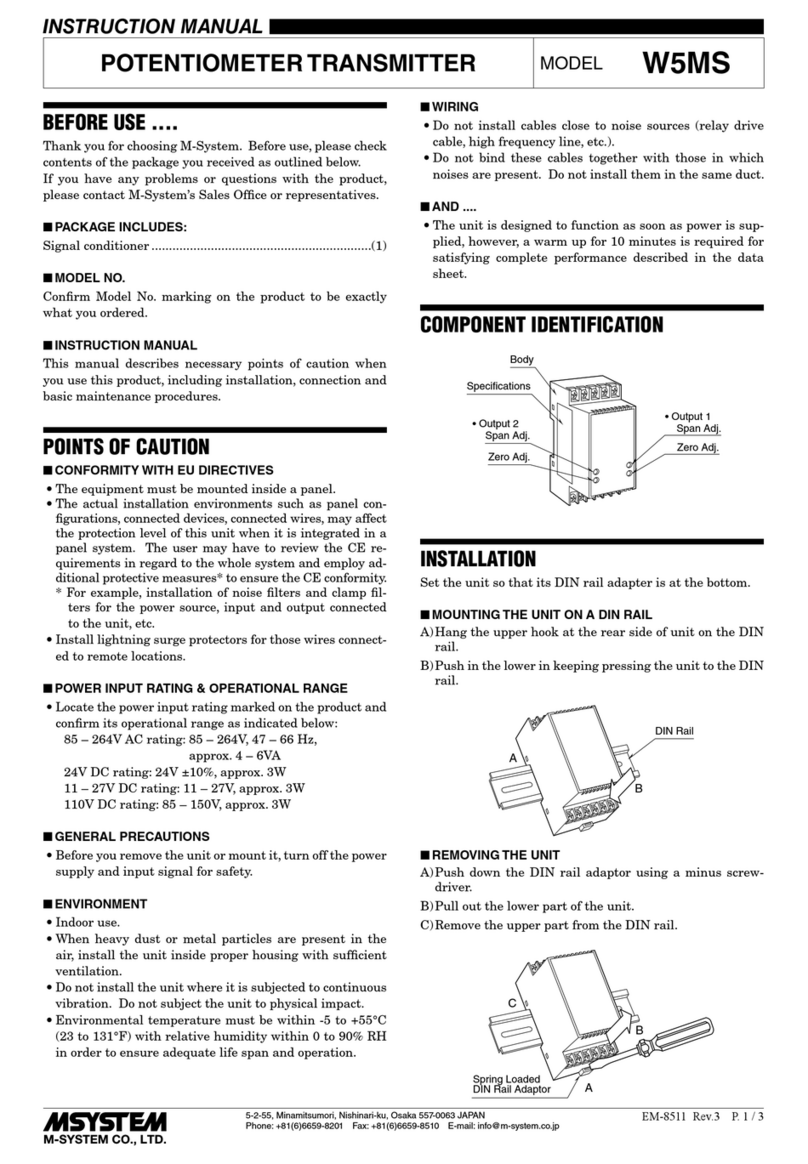

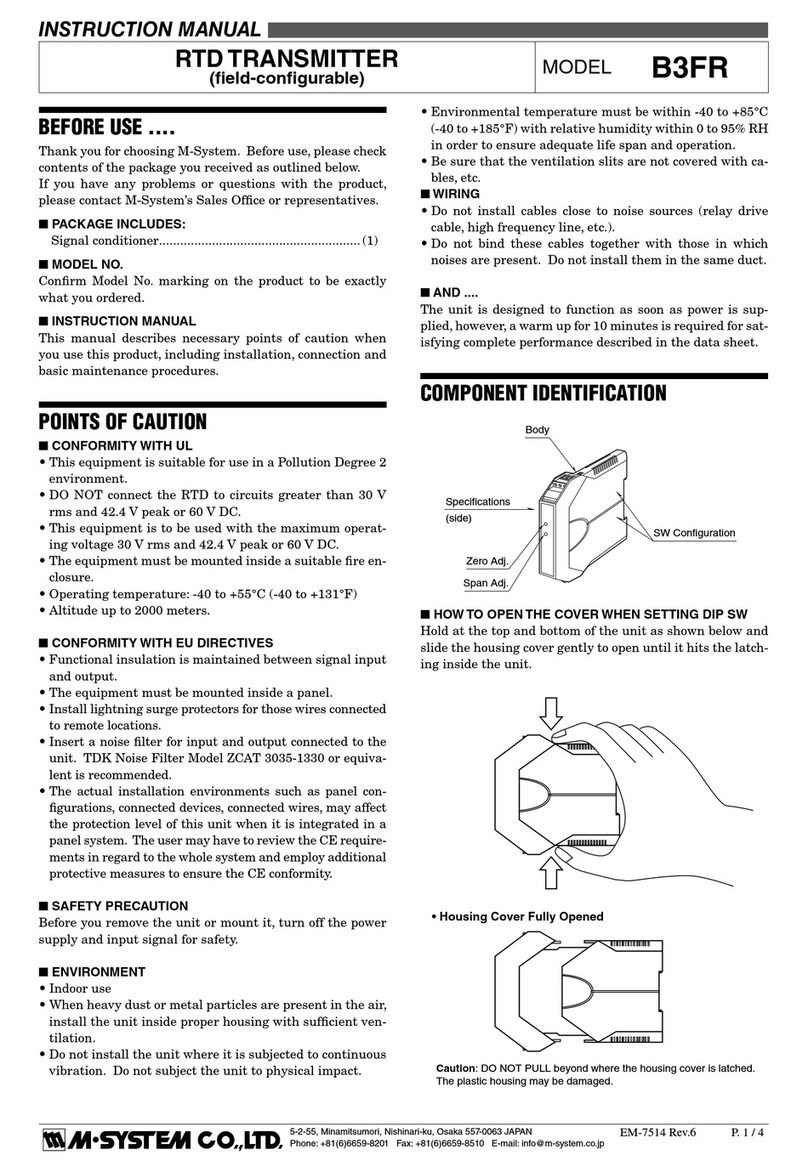

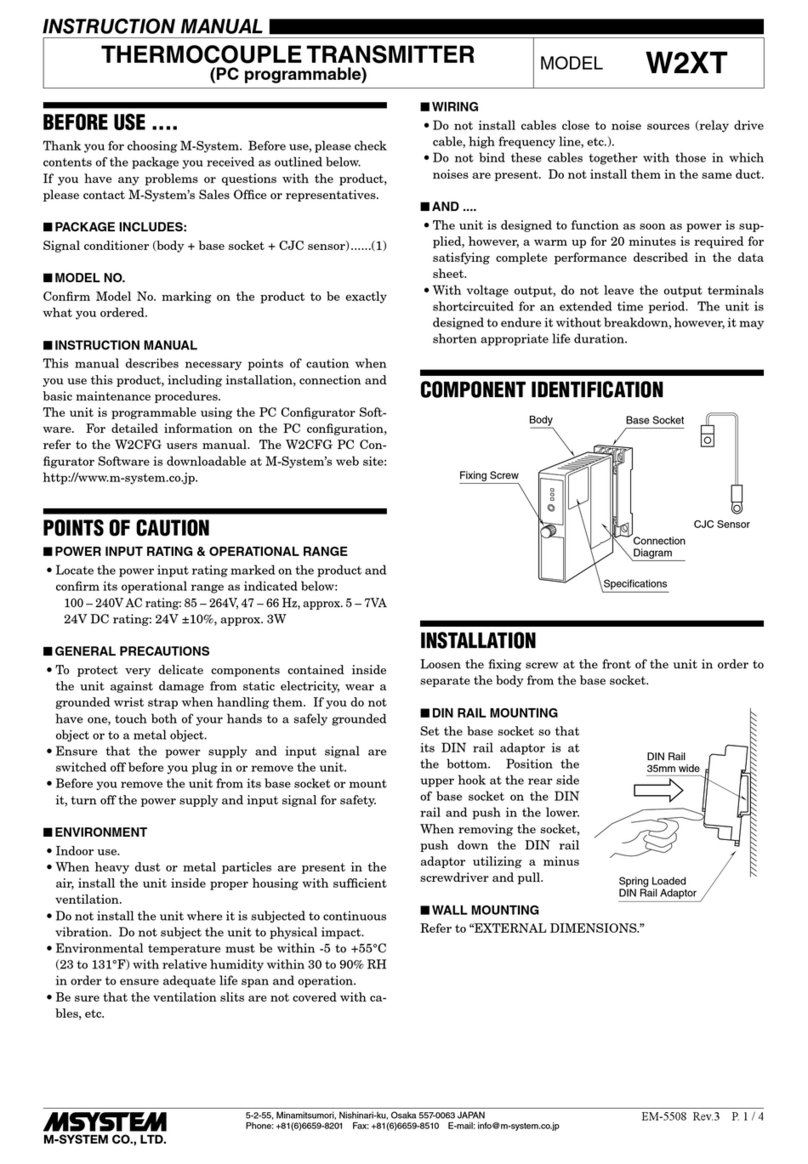

ELECTRICAL CONNECTIONS

Remove the VOS2T-R unit cover and wire to the terminals

according to Figure 6.

15 – 28V DC

LOAD

–

+

OUTPUT

4 – 20mA DC

Figure 6

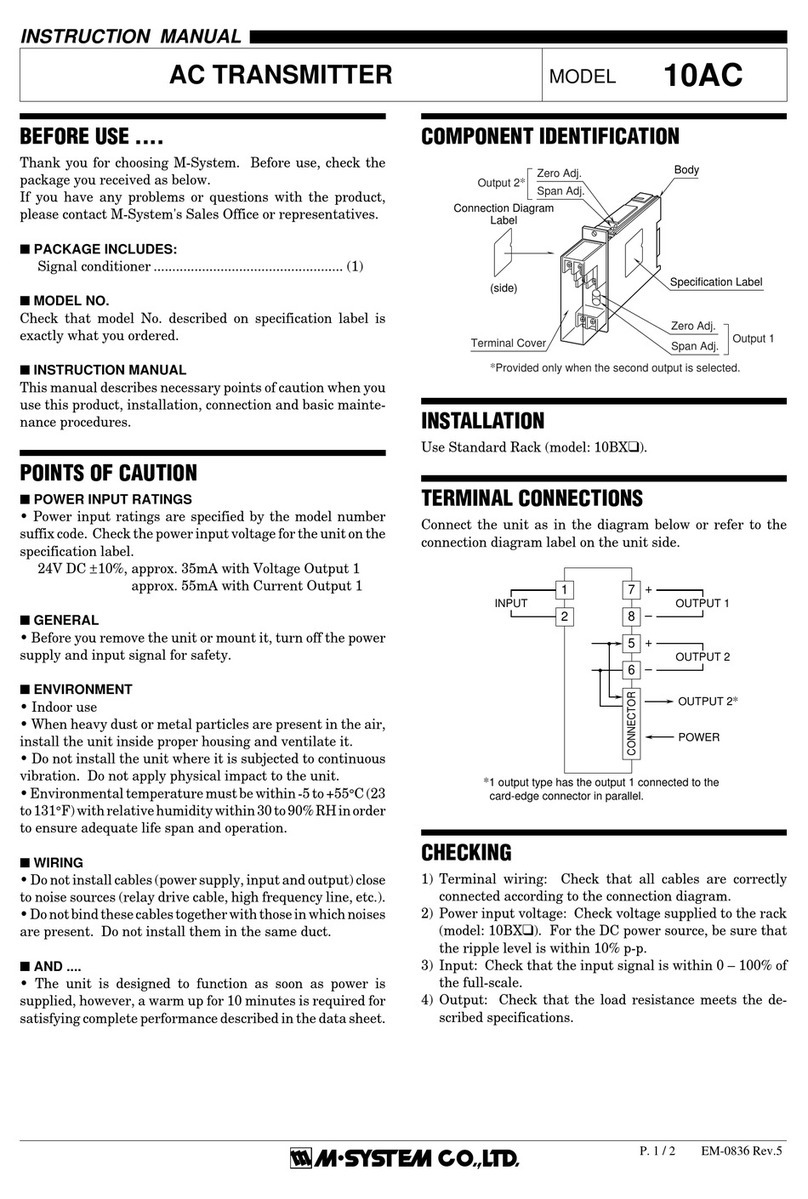

ADJUSTMENT PROCEDURE

First adjust the relative positions of levers and linking

mechanism.

After that, open the VOS2T-R unit cover. Set the action

direction* with jumpers (JP1, JP2 in Figure 1) and adjust

Zero (Z) and Span (S) behind it.

*Direct action: the output increases when the shaft turns

clockwise (seen from the lever side).

Reverse action: the output increases when the shaft turns

counterclockwise (seen from the lever side).

■HOW TO ADJUST LEVERS & LINKING MECHANISM

1) Electrical wires to the terminals should be done

before this adjustment. However, do not change each

potentiometer’s setting yet. Leave the jumper settings

for action direction as they were set at the factory (direct)

at this moment.

2) For using levers to link, loosen the VOS2T-R side nut

and washer and set the connecting pin (or bolt) position

relative to other components so that the distance A – B

and C – D is the same. See Figure 2. Tighten the nut and

washer.

3) For using the VOLK in combination with the VOS2T-R

lever, adjust lever length of the VOLK so that the distance

A – C and B – D is also the same. (The square A-B-C-D

must be a parallelogram or a rectangle.) Then tighten

the bolt.

If a customer provided lever is also adjustable of its

length, do the same.

4) With the actuator positioned at 50%, adjust the VOS2T-R

shaft angle with a wrench (7 mm) or by twisting the

indicator with your hand so that the VOS2T-R outputs

approx. 12mA. If you are using levers to link, tighten the

screw for lever now (torque 2.4 – 3.1 N·m). If you are not

using a lever, fix the coupling now.

5) Check the indicator and adjust its angle after loosening

its screw (M2.6) if necessary. Make sure that it is

tightened again after adjustment.

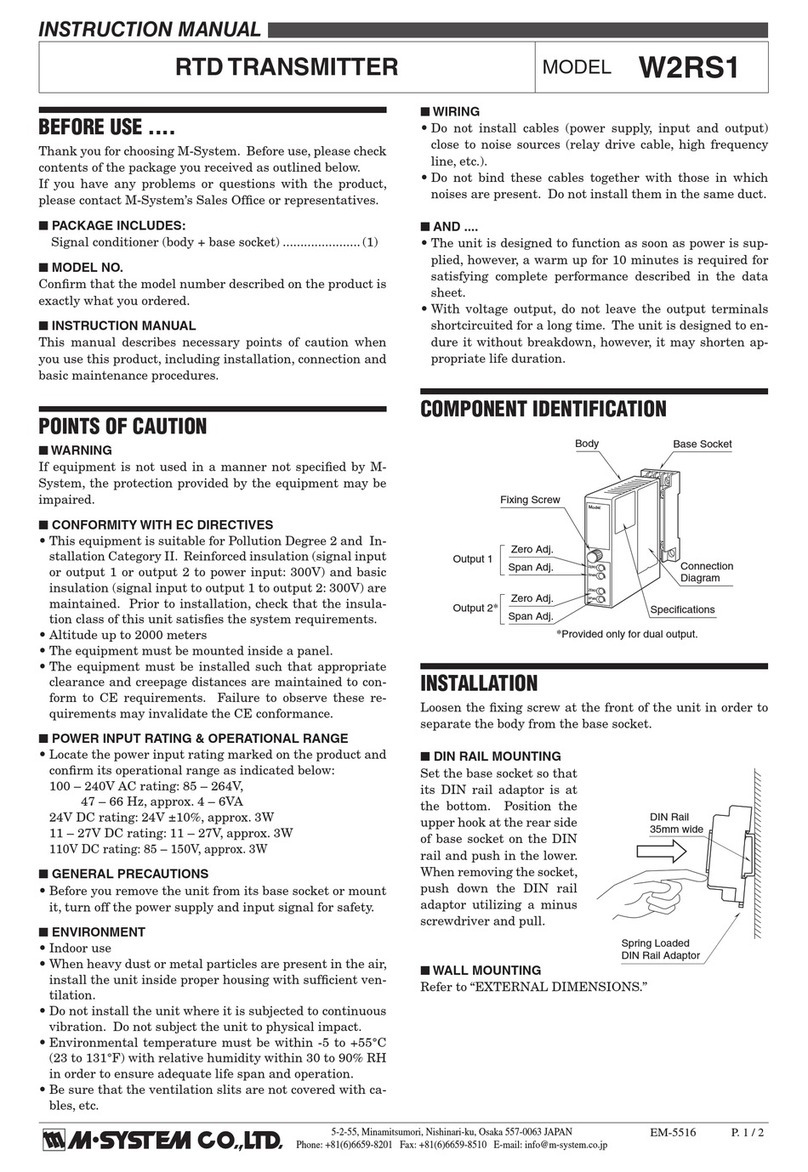

■HOW TO ADJUST ZERO AND SPAN

1) If you need reverse action, change the setting now.

Remove the cover and set the jumpers JP1 and JP2 to

R position according to Figure 1. Factory set zero point

may be slided by changing the action direction. Re-adjust

according to the following.

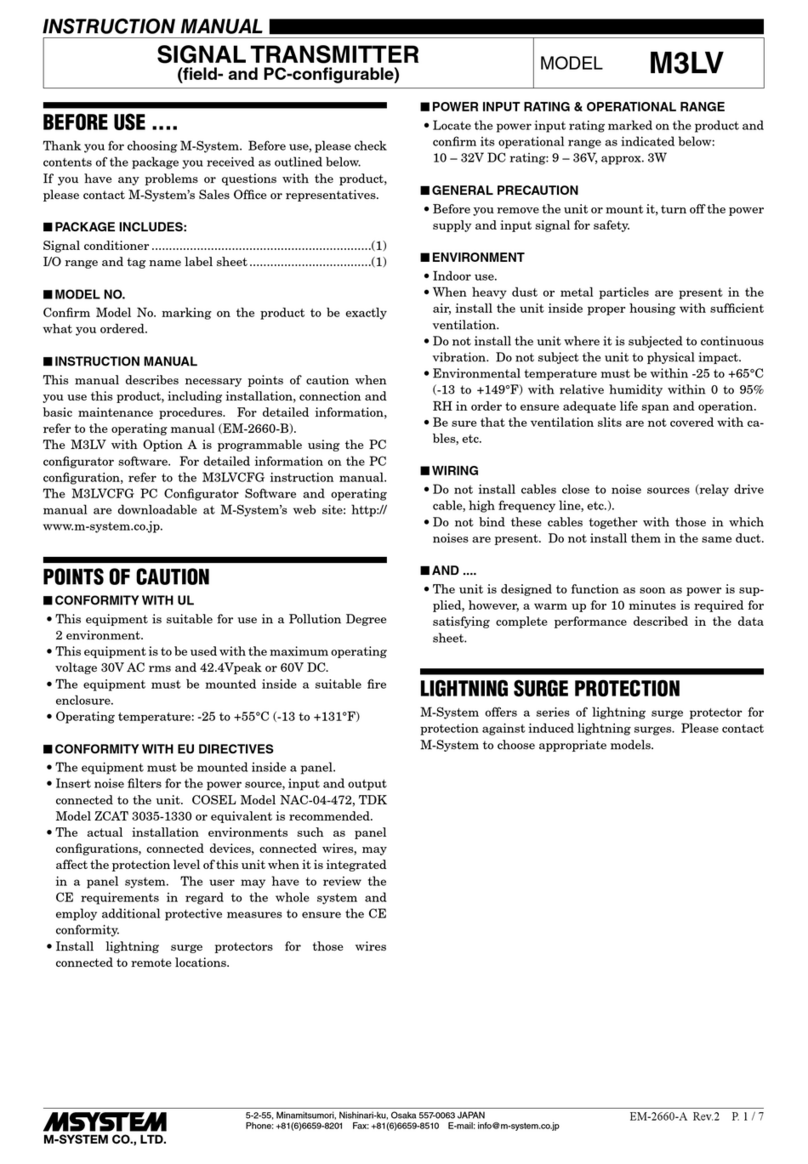

2) First operate the actuator

slowly for full-stroke (90°or

input angle after adjust-

ment) and check that the

VOS2T-R outputs approxi-

mately 0 – 100% (4 – 20mA

DC) accordingly. Be sure

also that the output signal

increases or decreases with-

out interruption.

3) With 50% input (actuator

position), check that the out-

put is approximately 50%.

See Figure 7.

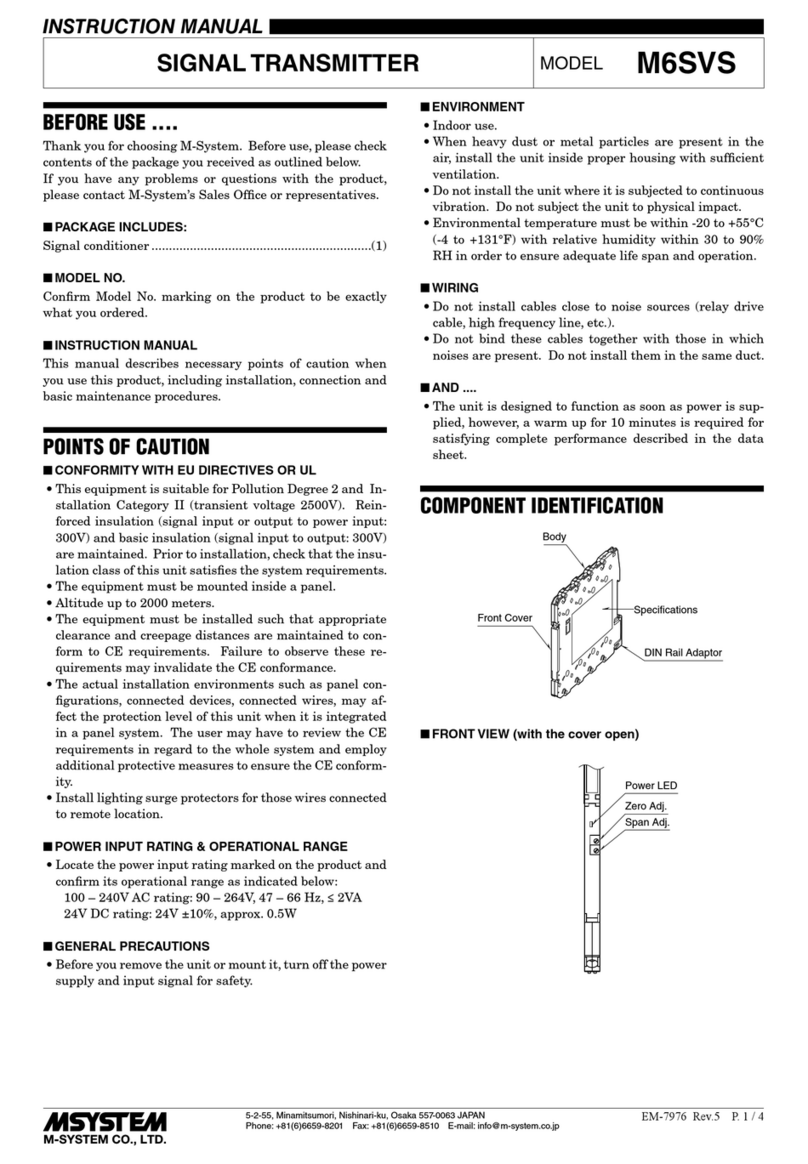

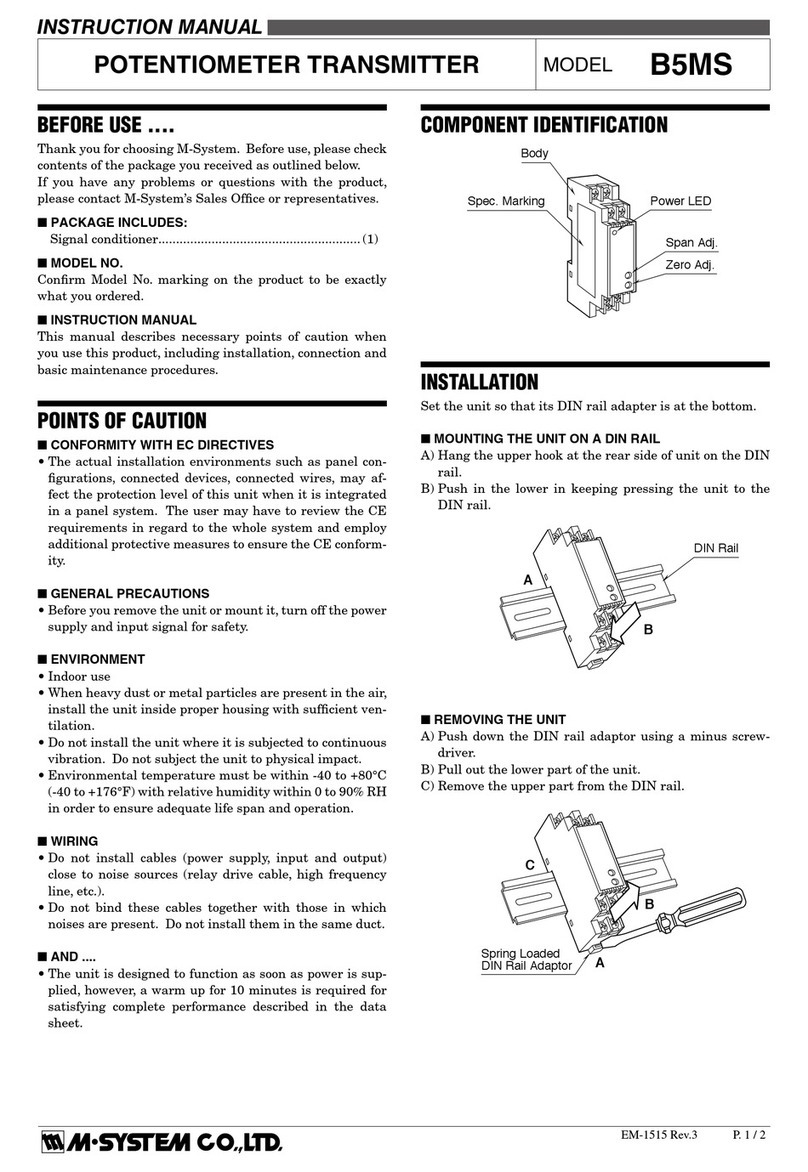

4) With 0% input, adjust the

output to 0% with Zero ad-

justment. See Figure 8.

5) Set the input to 100%. If

there is a deviation in out-

put signal, compensate half

of the deviation via the Zero

adjustment. See Figure 9.

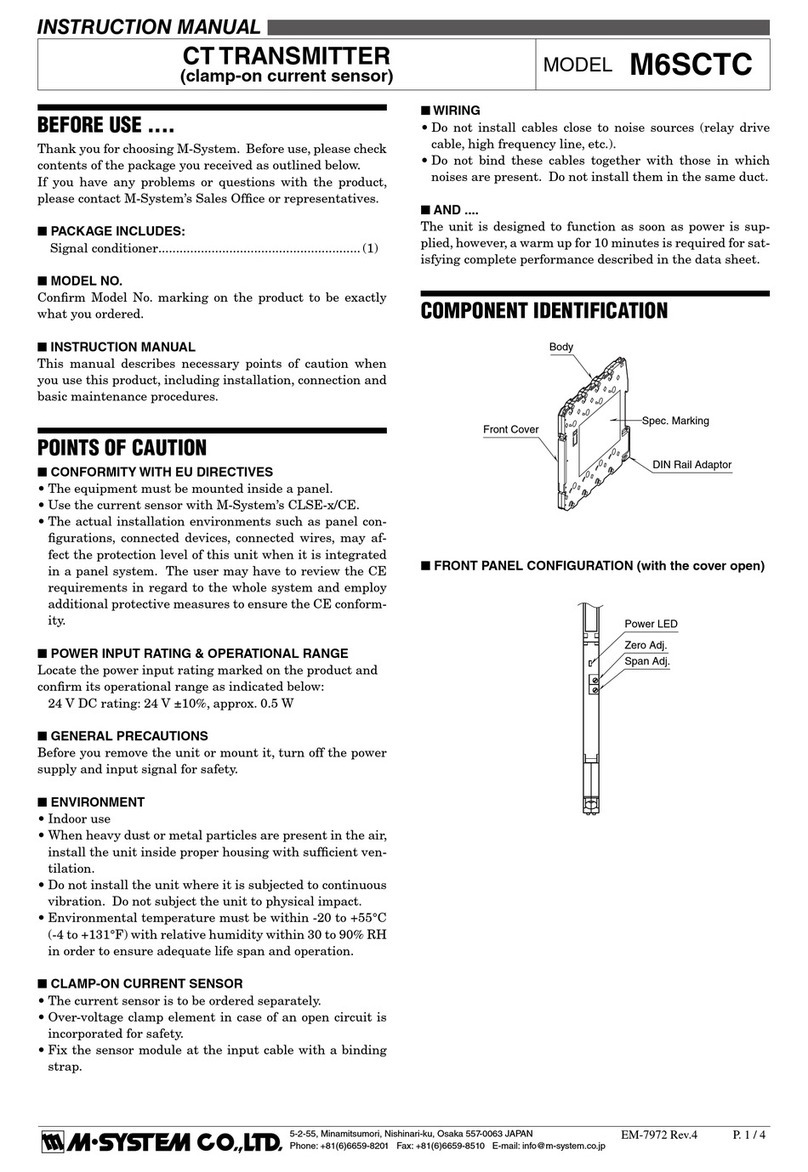

6) With 100% input, adjust the

other half of the deviation

with Span adjustment in or-

der to get 100% output. See

Figure 10.

7) Input 0%, 50% and 100%

signals and check the output

according to the respective

input value. If the output

value is shifted, repeat the

above procedure (3) – (6).

Note: If you set a wider output span (narrower input span),

the VOS2T-R does not output above or below the full-

scale range.

OUTPUT %

100

500 100

INPUT %

0

Fig. 7

OUTPUT %

100

500 100

INPUT %

0

Fig. 8

deviation

OUTPUT %

100

500 100

INPUT %

0

Fig. 9

1/2 deviation

OUTPUT %

100

500 100

INPUT %

0

Fig. 10

1/2 deviation