Form # 169242 Model Year - 2009

1

INTRODUCTION

This instruction describes the unloading, set-up and pre-delivery requirements for the MacDon M Series Self-

Propelled Windrowers. Use the table of contents to guide you to specific areas. Retain this instruction for

future reference.

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE,

OR USE THE MACHINE.

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................................1

GENERAL SAFETY...................................................................................................................................................3

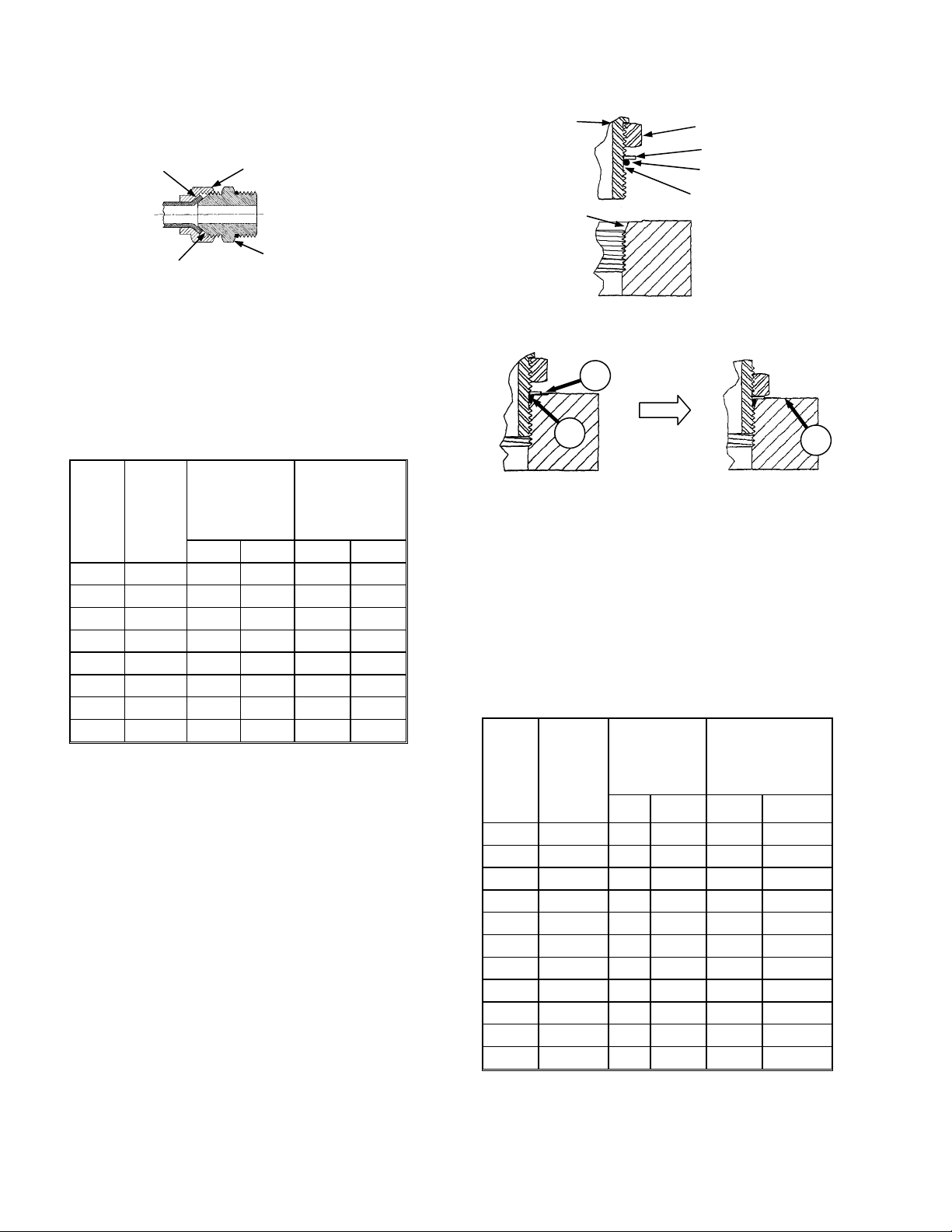

RECOMMENDED TORQUES ...................................................................................................................................5

A. GENERAL...............................................................................................................................................5

B. SAE BOLTS............................................................................................................................................5

C. METRIC BOLTS .....................................................................................................................................5

D. HYDRAULIC FITTINGS .........................................................................................................................6

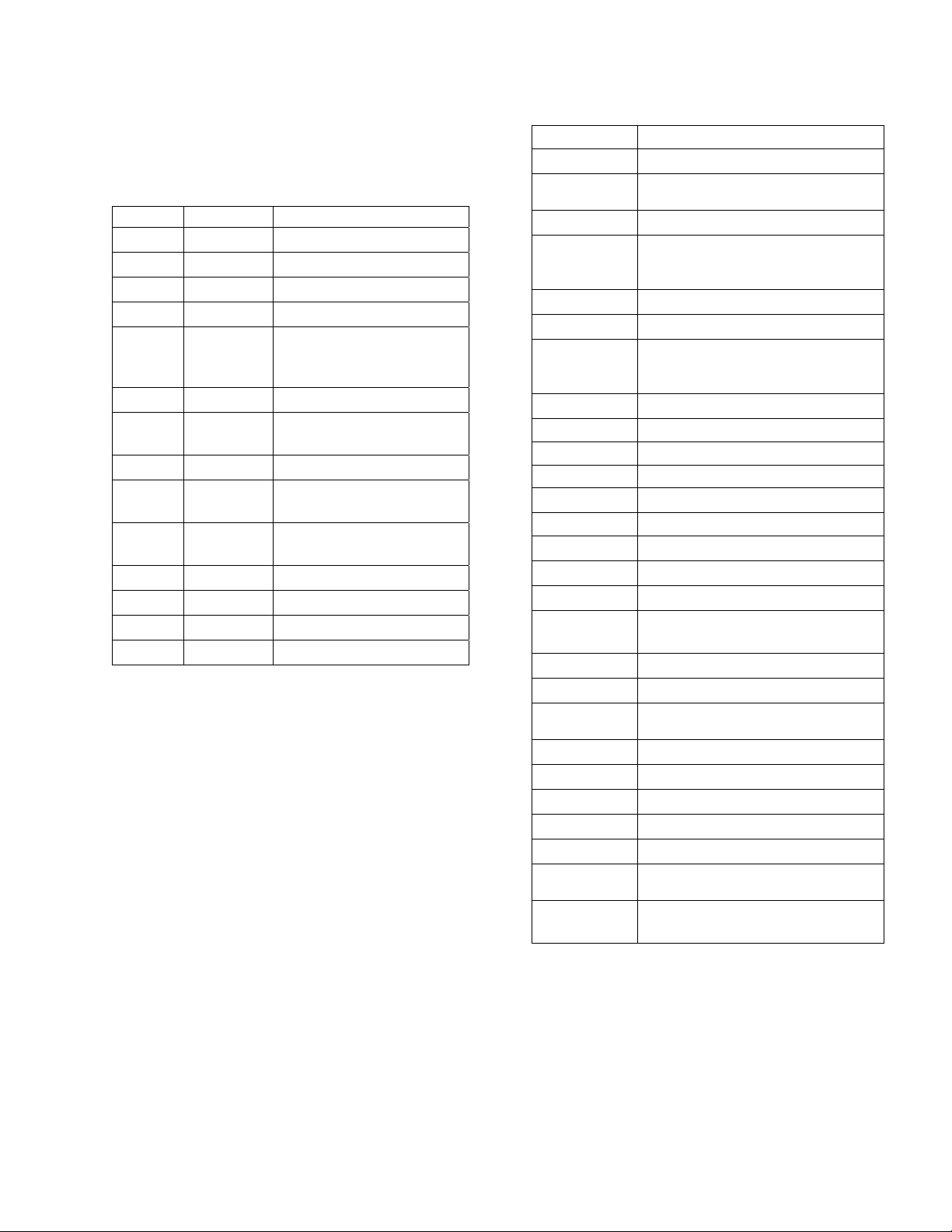

ACCRONYMS AND ABBREVIATIONS .....................................................................................................................7

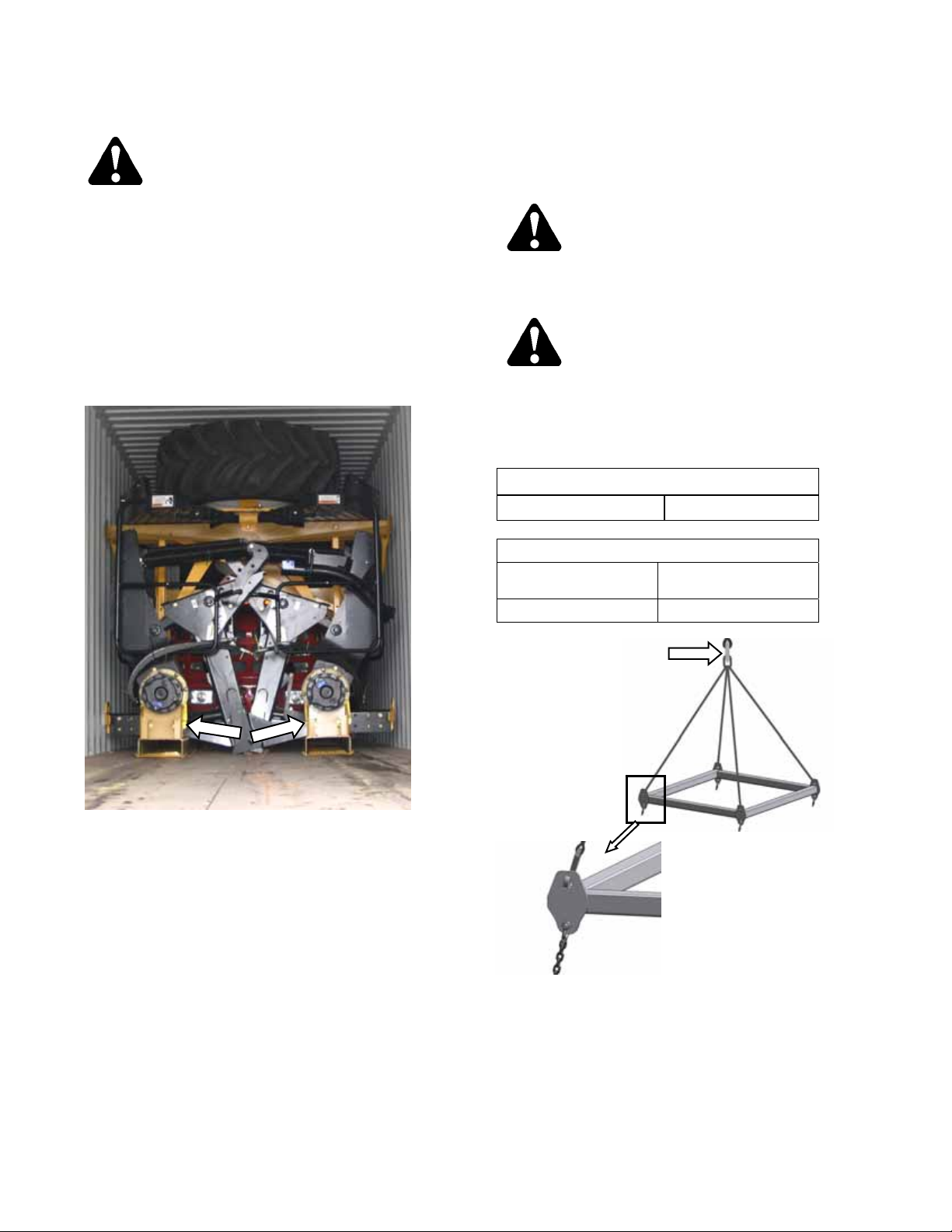

STEP 1. UNLOAD CONTAINER..............................................................................................................................8

STEP 2. MOVE TO ASSEMBLY AREA...................................................................................................................8

A. CRANE METHOD ..................................................................................................................................8

B. FORKLIFT METHOD..............................................................................................................................9

STEP 3. REMOVE WHEEL & STEP ASSEMBLY .................................................................................................11

STEP 4. REMOVE DRIVE WHEELS ..................................................................................................................... 13

STEP 5. REMOVE PLATFORM/LIGHT ASSEMBLY ............................................................................................14

STEP 6. INSTALL LIGHT AND MIRROR ASSEMBLIES ...................................................................................... 15

STEP 7. REMOVE LEG ASSEMBLIES ................................................................................................................. 17

STEP 8. REMOVE WHEEL & PLATFORM SUPPORT.........................................................................................18

STEP 9. ASSEMBLE WINDROWER TRACTOR SUPPORT STAND................................................................... 18

STEP 10. LIFT WINDROWER TRACTOR ONTO STAND......................................................................................19

A. CRANE METHOD ................................................................................................................................19

B. FORKLIFT METHOD............................................................................................................................20

STEP 11. INSTALL LEGS........................................................................................................................................21

STEP 12. INSTALL FRONT WHEELS.....................................................................................................................23

STEP 13. INSTALL CASTER WHEELS ..................................................................................................................25

STEP 14. INSTALL HYDRAULICS ..........................................................................................................................27

A. M150, M200..........................................................................................................................................27

B. M100.....................................................................................................................................................31

STEP 15. INSTALL PLATFORMS ...........................................................................................................................34

STEP 16. INSTALL STEPS......................................................................................................................................36

STEP 17. INSTALL TOOLBOX................................................................................................................................36

STEP 18. INSTALL BATTERIES .............................................................................................................................37

A. M150, M200..........................................................................................................................................37

B. M100.....................................................................................................................................................37

STEP 19. PRIME HYDRAULIC SYSTEM................................................................................................................38

STEP 20. START ENGINE ......................................................................................................................................41

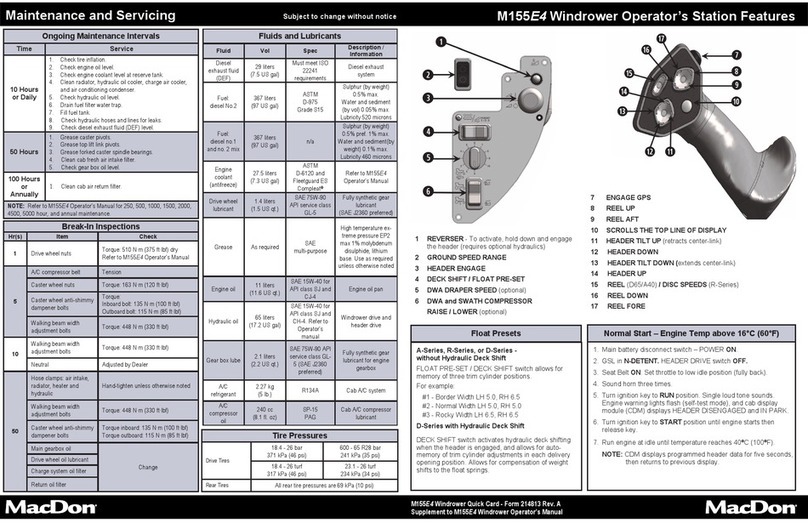

STEP 21. CHECK TRACTION DRIVE.....................................................................................................................43

STEP 22. REMOVE WINDROWER TRACTOR FROM STAND .............................................................................44

A. FACTORY STAND ...............................................................................................................................44

B. FIELD CONSTRUCTED STAND..........................................................................................................44

STEP 23. INSTALL AM/FM RADIO .........................................................................................................................45

STEP 24. INSTALL BEACONS................................................................................................................................47

STEP 25. ATTACH HEADER...................................................................................................................................48

A. HEADER ATTACHMENT - D SERIES.................................................................................................48

B. HEADER ATTACHMENT – A SERIES ................................................................................................52

C. HEADER ATTACHMENT – R SERIES (M150, M200 ONLY)..............................................................55

STEP 26. LUBRICATE MACHINE ...........................................................................................................................59

STEP 27. PROGRAM CDM .....................................................................................................................................61