214882 iii Revision C

Introduction ................................................................................................................................................i

Summary of Changes....................................................................................................................................ii

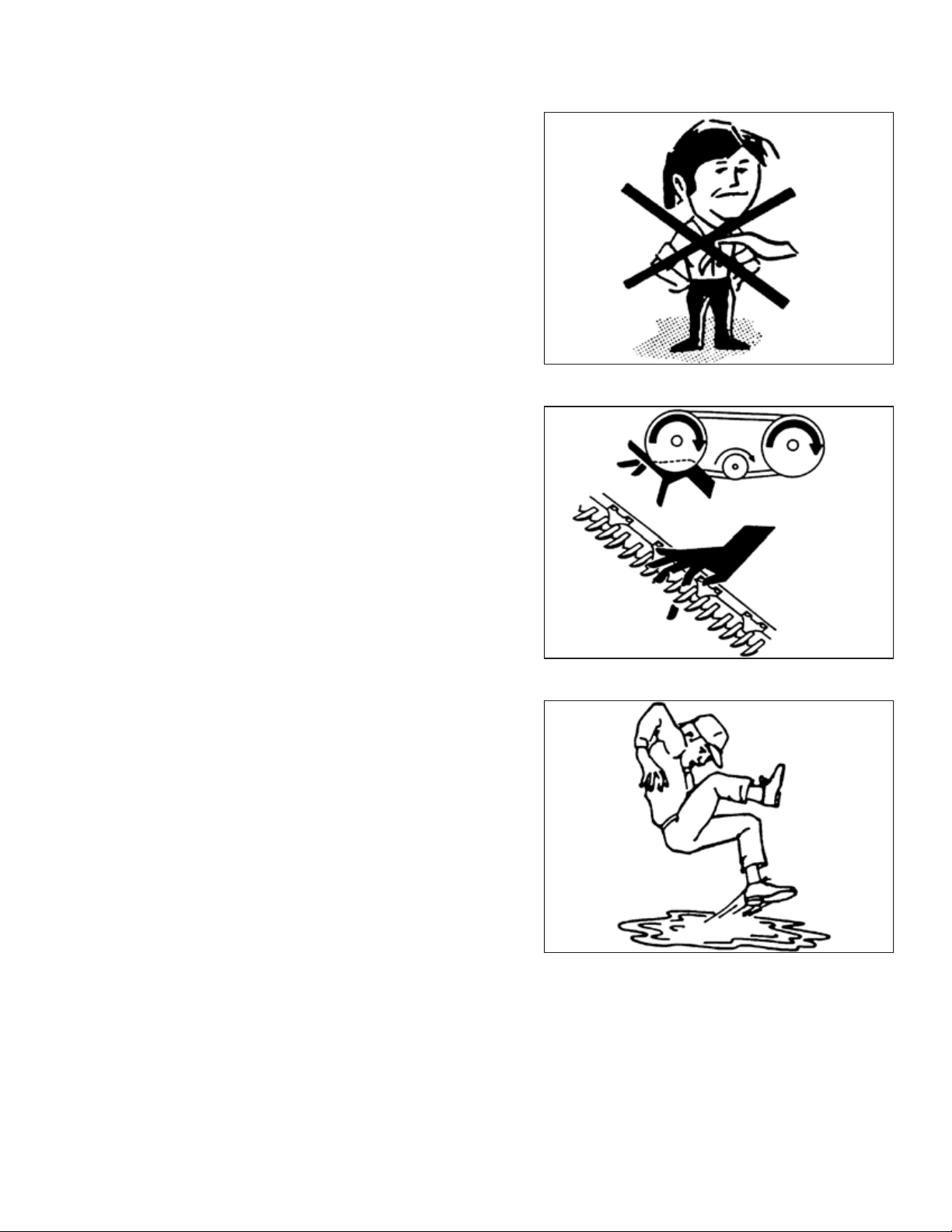

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Signal Words .........................................................................................................................................1

1.2 General Safety .......................................................................................................................................2

1.3 Welding Precaution ................................................................................................................................4

1.4 Safety Signs ...........................................................................................................................................5

Chapter 2: Unloading the Header .............................................................................................................. 7

Chapter 3: Assembling the Header ............................................................................................................ 9

3.1 Removing Shipping Supports ....................................................................................................................9

3.1.1 Installing Adjustable Gauge Roller Kit............................................................................................... 12

3.1.2 Installing Adjustable Skid Shoes Kit.................................................................................................. 15

3.2 Lowering the Header............................................................................................................................. 18

3.3 Unpacking Hydraulic Hoses and Electrical Harness...................................................................................... 20

3.4 Removing Shipping Stands ..................................................................................................................... 21

3.5 Adjusting Rear Baffle Deflectors .............................................................................................................. 23

3.6 Unpacking Curtain ................................................................................................................................ 25

Chapter 4: Attaching Header to M1240 Windrower............................................................................... 27

4.1 Assembling and Installing Forming Shield.................................................................................................. 27

4.2 Routing Electrical Harness ...................................................................................................................... 35

4.3 Attaching Disc Header ........................................................................................................................... 38

4.4 Connecting Rotary Disc Header Hydraulics Using Quick Couplers .................................................................. 45

4.5 Connecting Disc Header Hydraulics Using Hard Plumbing ............................................................................ 47

4.6 Restoring Float for Disc Header............................................................................................................... 50

4.7 Calibrating Windrower Knife Drive on the Harvest Performance Tracker Display.............................................. 52

Chapter 5: Installing Options.................................................................................................................... 55

5.1 Electric Remote Baffle Kit....................................................................................................................... 55

5.2 Crop Dividers Kit................................................................................................................................... 56

5.3 Adjustable Gauge Roller Kit .................................................................................................................... 58

5.4 Adjustable Skid Shoes Kit ....................................................................................................................... 59

Chapter 6: Lubricating the Disc Header................................................................................................... 61

6.1 Lubrication Locations ............................................................................................................................ 62

Chapter 7: Performing Predelivery Checks.............................................................................................. 65

7.1 Conditioner Drive Belt ........................................................................................................................... 65

7.1.1 Inspecting Conditioner Drive Belt.................................................................................................... 65

7.1.2 Adjusting Conditioner Drive Belt ..................................................................................................... 66

TABLE OF CONTENTS