3

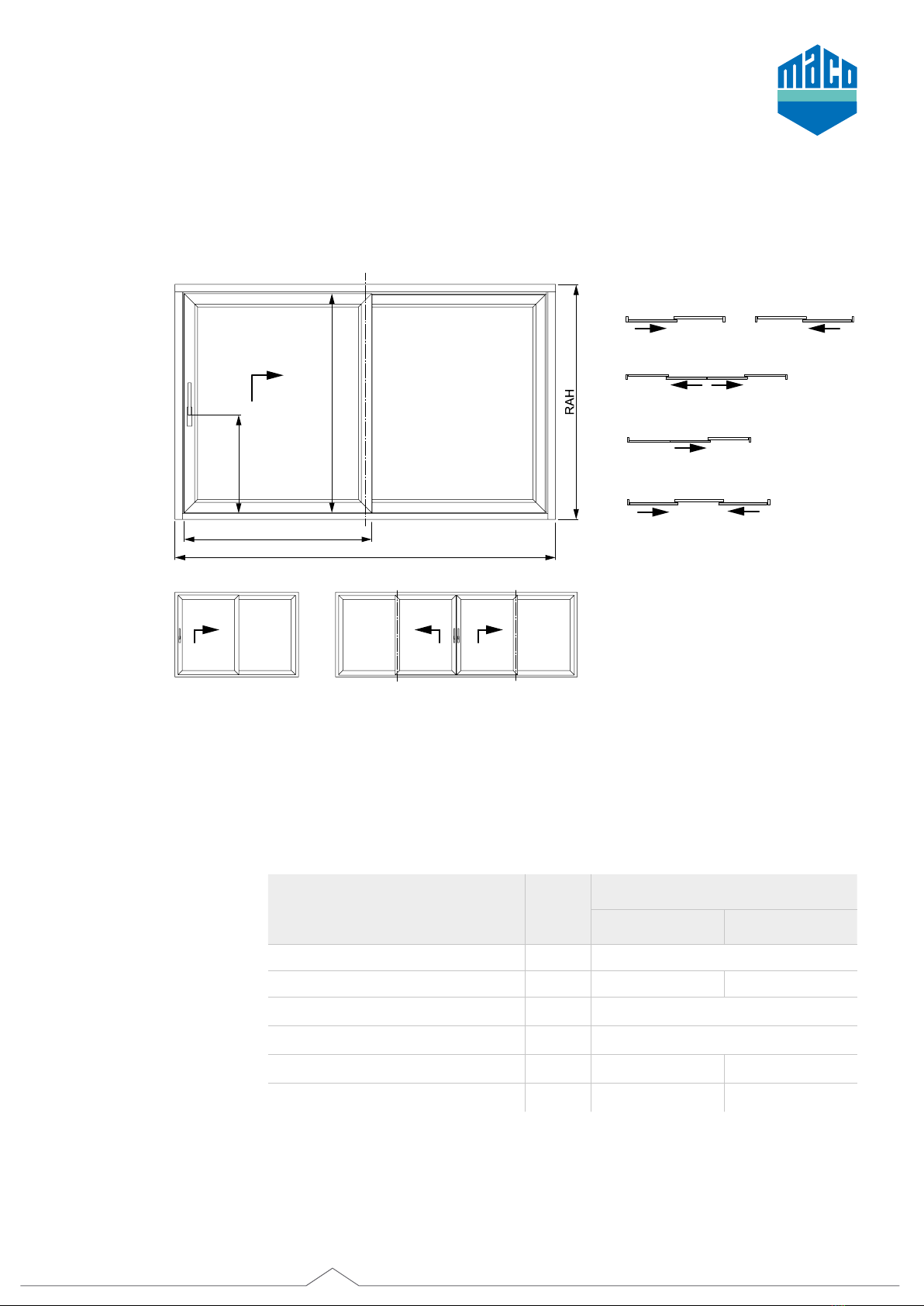

WINDOWS · DOORS · SLIDING DOORS

Target group

Thisdocumentationisintendedexclusivelyforspecialistcompaniesandcertiedspecialists.

Theworkdescribedmayonlybecarriedoutbyspecialistpersonnel.

Instructions for use and safety

Assemble all hardware parts professionally as described in this manual and observe all safety

instructions.

Overloading or improper operation of the lift and slide hardware may cause the sash to jump

outofitsguide,falloutandcauseseriousinjury.Ifoverloadingoftheliftandslidehardwareis

expectedunderspecialcircumstances,suchasinSchools,Kindergartensetc.,thismustbe

prevented using the appropriate measures,

e.g.

• Adjustmentofthebuerstoptoreducetheopeningwidth,or

• Installationofaprolecylindertopreventimproperuse.

Pleaseobservethetermsofourfunctionalwarranty(https://www.maco.eu/assets/757813)as

wellastheconditionsofoursurfacewarrantyforMACOTRICOAT-PLUShardware

(https://www.maco.eu/assets/757713).

Observethe“GuidelinesandInstructionsonProductandLiability(GIPL)”oftheQuality

AssociationofLocksandHardware.Thispolicydescribesallsafety-relatedissuesfor

end-usersforwindowandbalconydoortopics.(Downloadavailableonthewebsiteofthe

QualityAssociationofLocksandHardware).

For MACO lift and slide hardware HS, the application ranges given on page 6 must not be

exceeded.Inaddition,PROFINE‘sspecicationsfortheliftandslidedoorhardware,in

particular on possible restrictions on sash dimensions and sash weight, must be strictly

adheredto.

AssemblethecompletehardwareonlyfromMACOhardwarepartsandtherequiredPROFINE

accessories.

WhenusingAccoya(registeredtrademarkofTitanWoodLimited)andacid-treatedwoods(e.g.

Oak,Teak,Larch),useonlytheTRICOAT-PLUSttings.

Usethespeciedscrewsizesasspeciedinthisguide.

Turnthescrewsstraight(unlessotherwisestated)anddonotover-tighten,otherwisesmooth

operationofthehardwaremaybeimpaired.

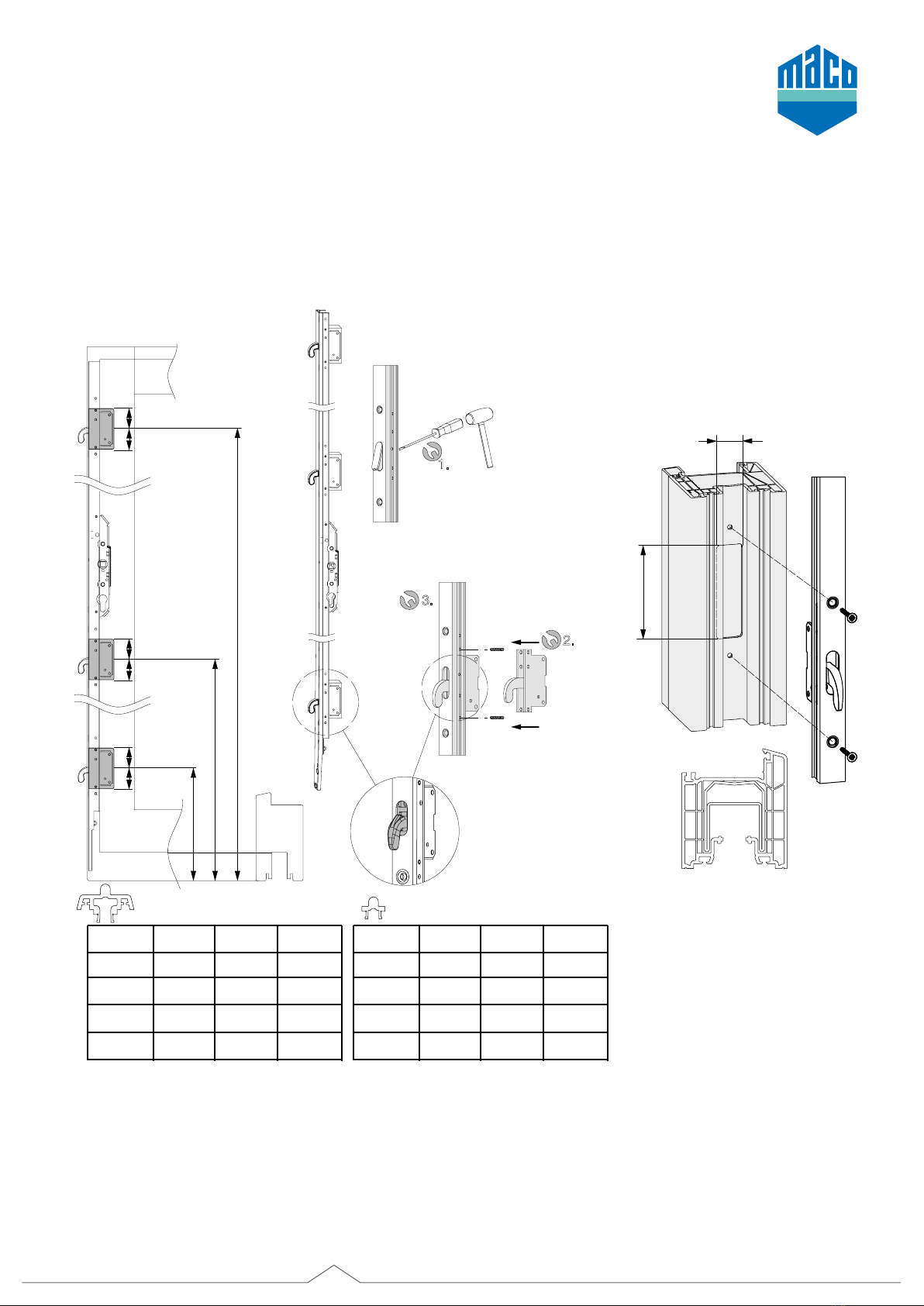

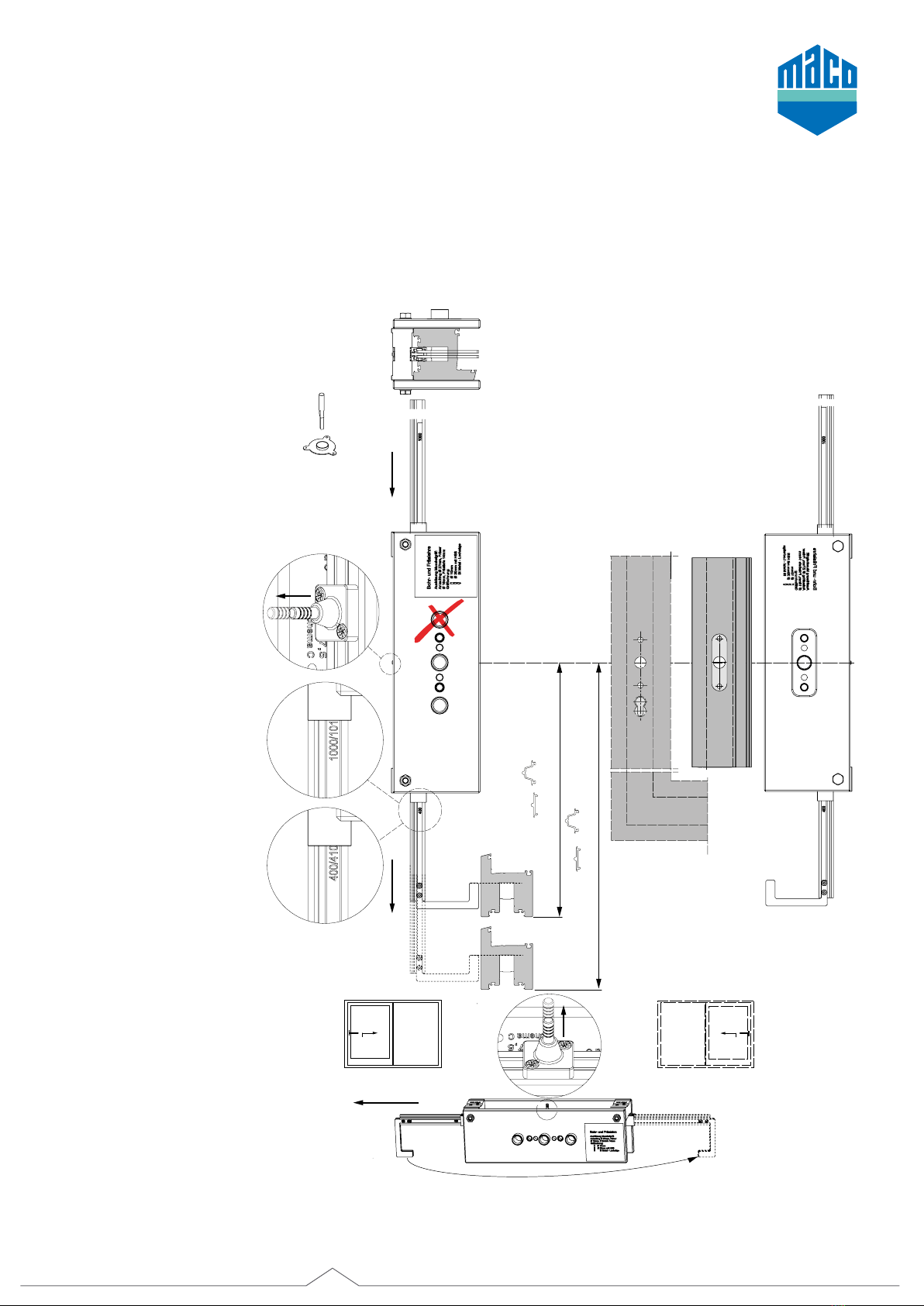

Fixthescrewsofthesupportingcomponents(e.g.rollers,runningrailandguiderail)intherein-

forcementprole.

Around the rollers, ensure a positive transfer of the compressive forces onto the reinforcement

prole!

Withthespacer-blocksetting,observethetechnicalguidelineNo.3oftheglaziertrade

“Blockingofglazingunits”.

Donotuseacid-curingsealants,asthesecanleadtocorrosionofthehardwareparts.

Importantinformation