3

SAFETY INSTRUCTIONS

General Instructions

To ensure correct and safe operation, the user must read, understand and

follow this instruction manual to assure familiarity with the handling of the

blower (1). Users insufciently informed will risk danger to themselves as

well as others due to improper handling.

It is recommended only to loan the blower to people who have proven to

be experienced with blowers.

Always hand over the instruction manual.

First-time users should ask the dealer for basic instructions to familiarize

oneself with the handling of a blower.

Children and young persons aged under 18 years must not be allowed

to operate the blower. Persons over the age of 16 years may however

use the tool for the purpose of being trained only while under the direct

supervision of a qualied trainer.

Use blowers with the utmost care and attention.

Operate the blower only if you are in good physical condition.

Perform all work conscientiously and carefully. The user has to accept

responsibility for others.

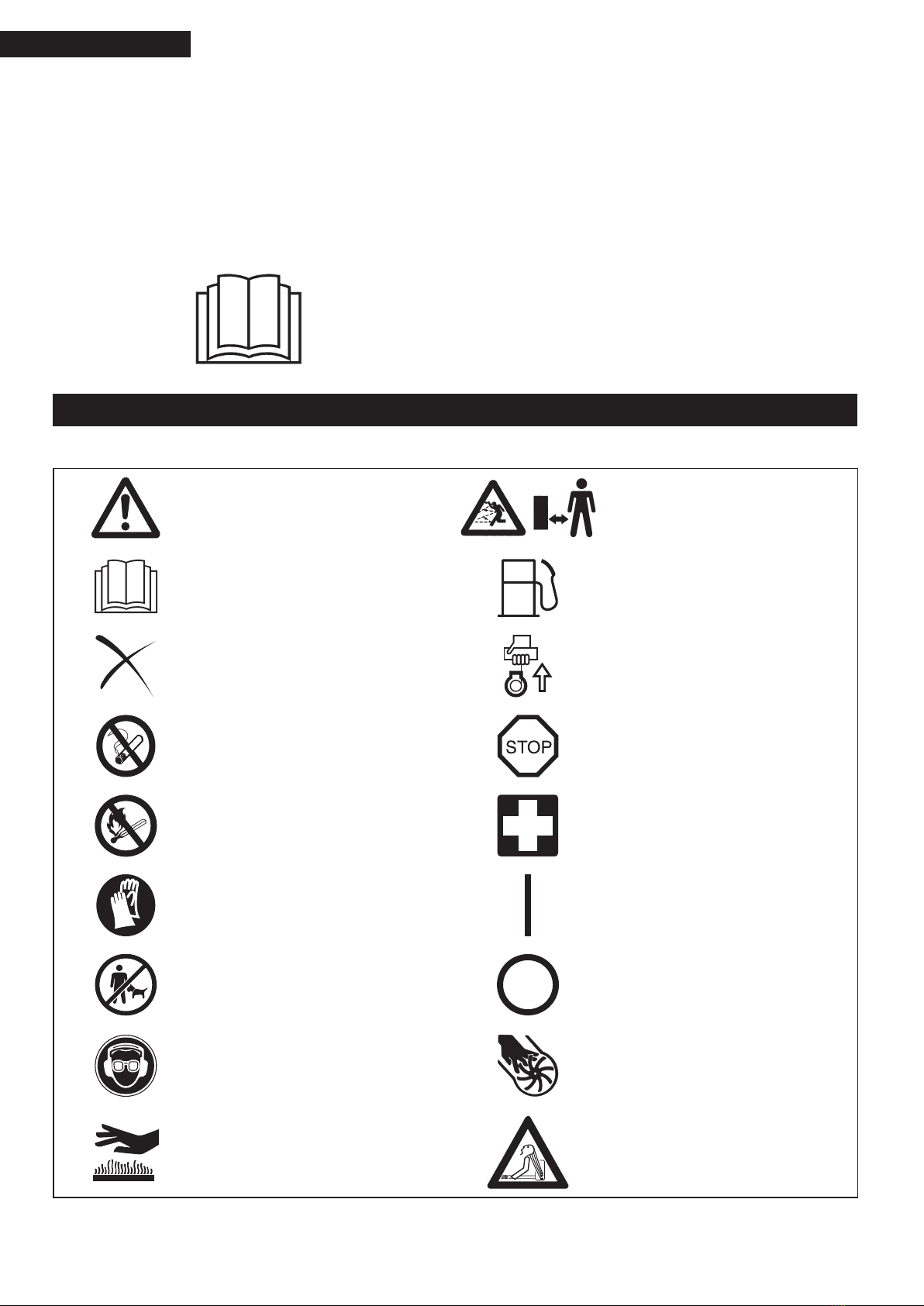

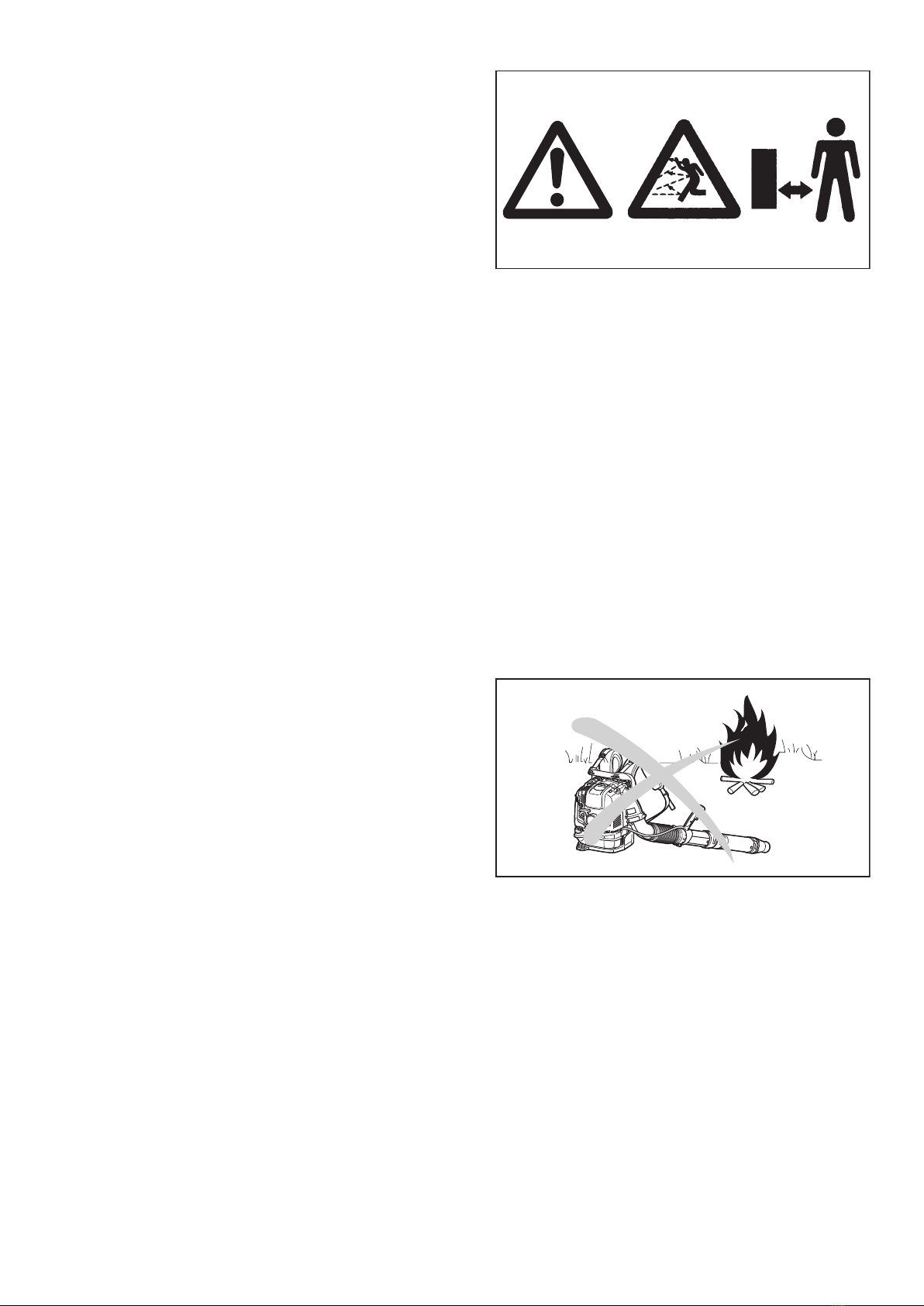

Never use the blower while under the inuence of alcohol or drugs (2).

Do not use the unit when you are tired.

Save these instructions for future referral.

Personal Protective Equipment

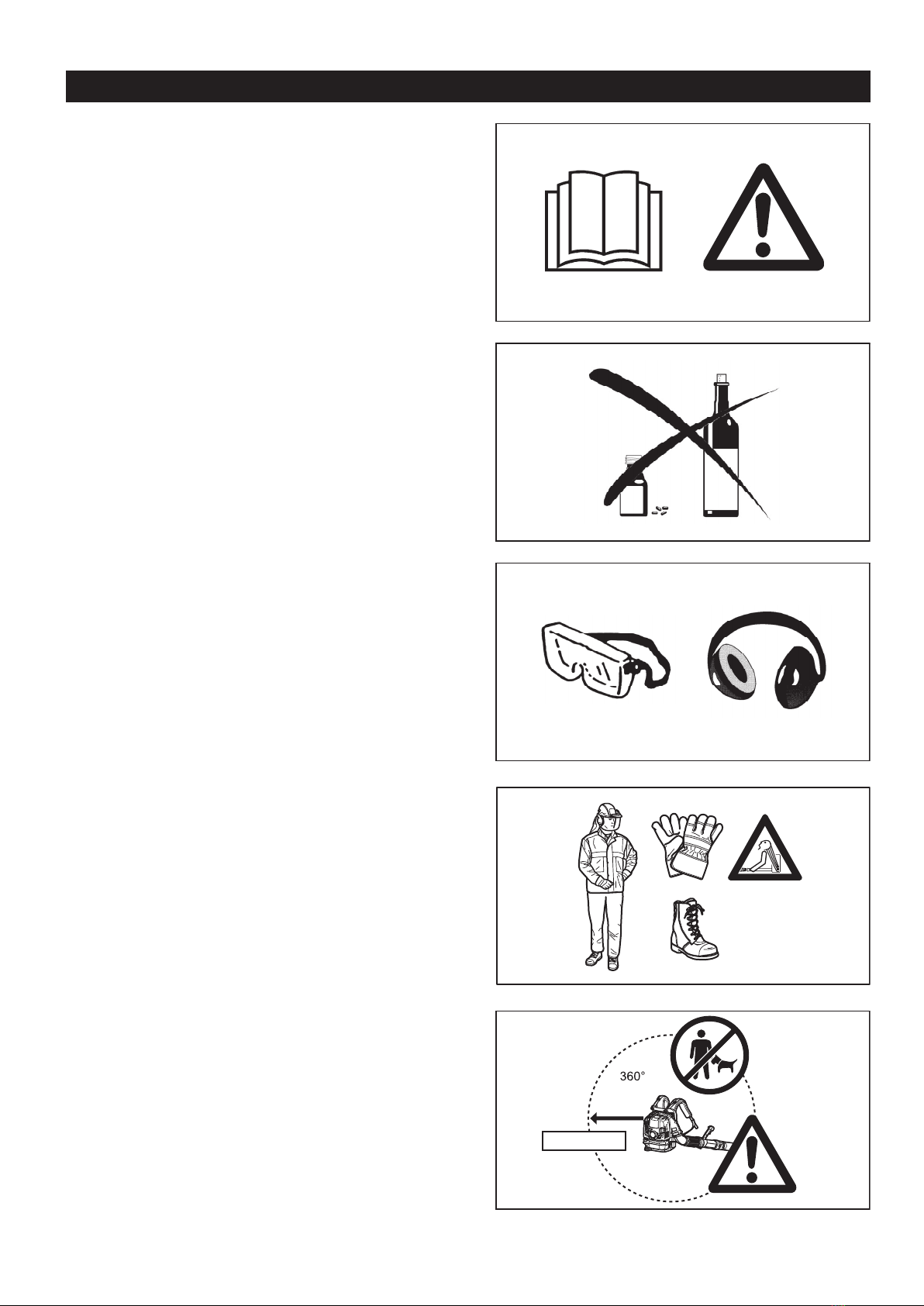

The clothing worn should be functional and appropriate, i. e., it should

be tight tting but not cause a hindrance. Do not wear jewelry, clothing or

long hair which could be drawn into the air intake.

In order to avoid head-, eye-, hand- or foot injuries as well as to protect

your hearing the following protective equipment and protective clothing

must be used during operation of the blower.

Pay particular attention to the following regulations

Clothing must be sturdy and snug-tting, but allow complete freedom of

movement. Avoid loose-tting jackets, ared or cuffed pants, scarves,

unconned long hair or anything that could be drawn into the air intake. (4)

Wear overalls or long pants to protect your legs.

Do not wear shorts. (4)

Generally, engine products are noisy and their noise may damage your

hearing. Wear sound barriers (ear plugs or ear mufers) to protect your

hearing. Continual and regular users should have their hearing checked

regularly. (3)

Use of gloves when working with the blower is recommended.

Wear sturdy shoes with non-slip soles. (4)

Proper eye protection is a must. Even though the discharge is directed

away from the operator, ricochets and bounce-backs can occur during

blower operation. (3)

Never operate a blower unless wearing goggles or properly tted safety

glasses with adequate top and side protection which comply with EN166

and regulations in your country.

To reduce the risk of injury associated with the inhalation of dust, use

face lter mask in dusty conditions.

Starting up the blower

Make sure that there are no children or other people within a working

range of 15 meters (5), also pay attention to any animals in the working

vicinity. Never use the blower in urban areas.

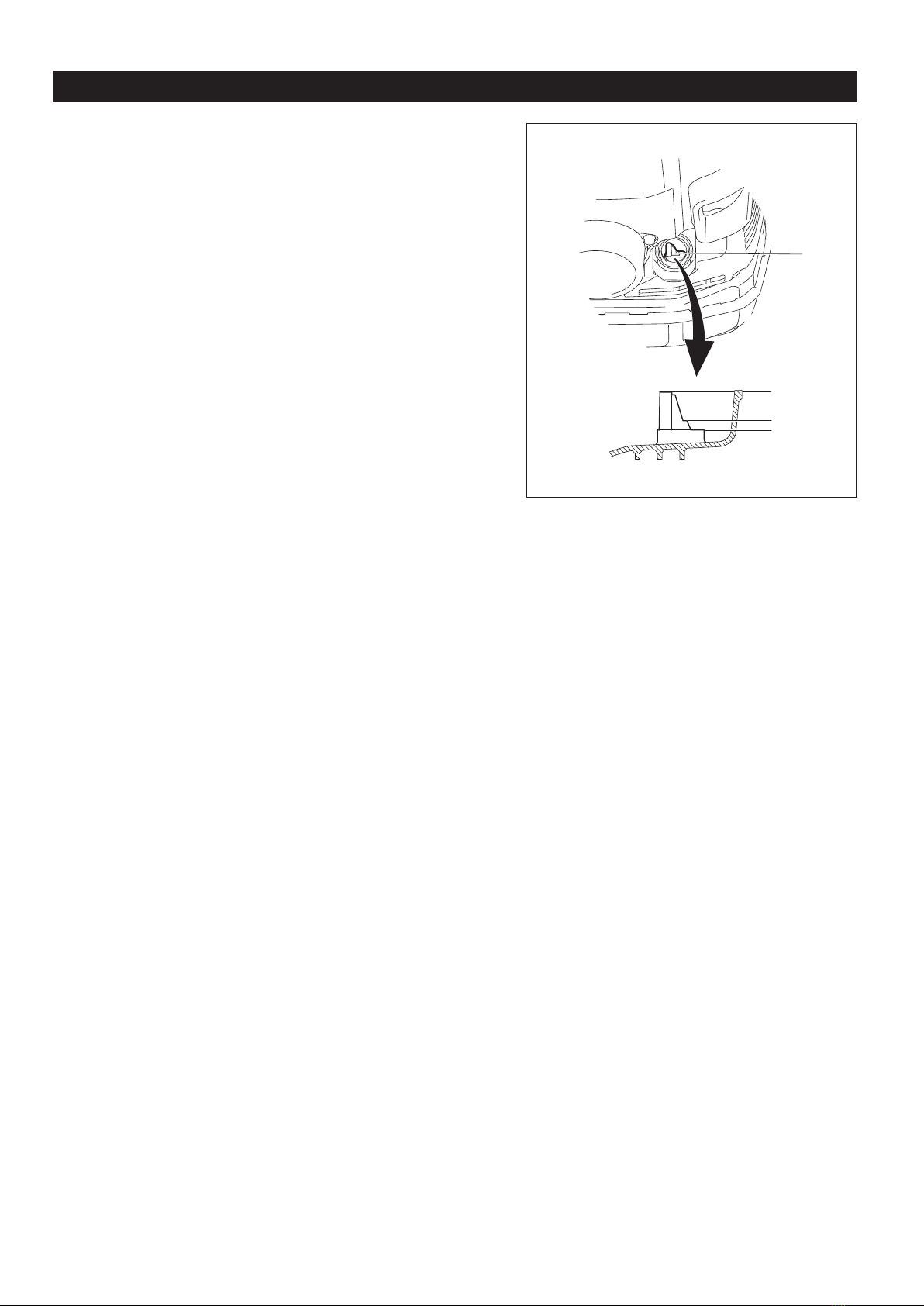

Before operating, always check that the blower is safe for operation:

Check the security of the throttle lever. The throttle lever should be

checked for smooth and easy action. Check for proper functioning of the

throttle lever lock. Check for clean and dry handles and test the function

of the l-O switch. Keep handles free of oil and fuel.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

15 meters