10 ENGLISH

ENGLISH (Original instructions)

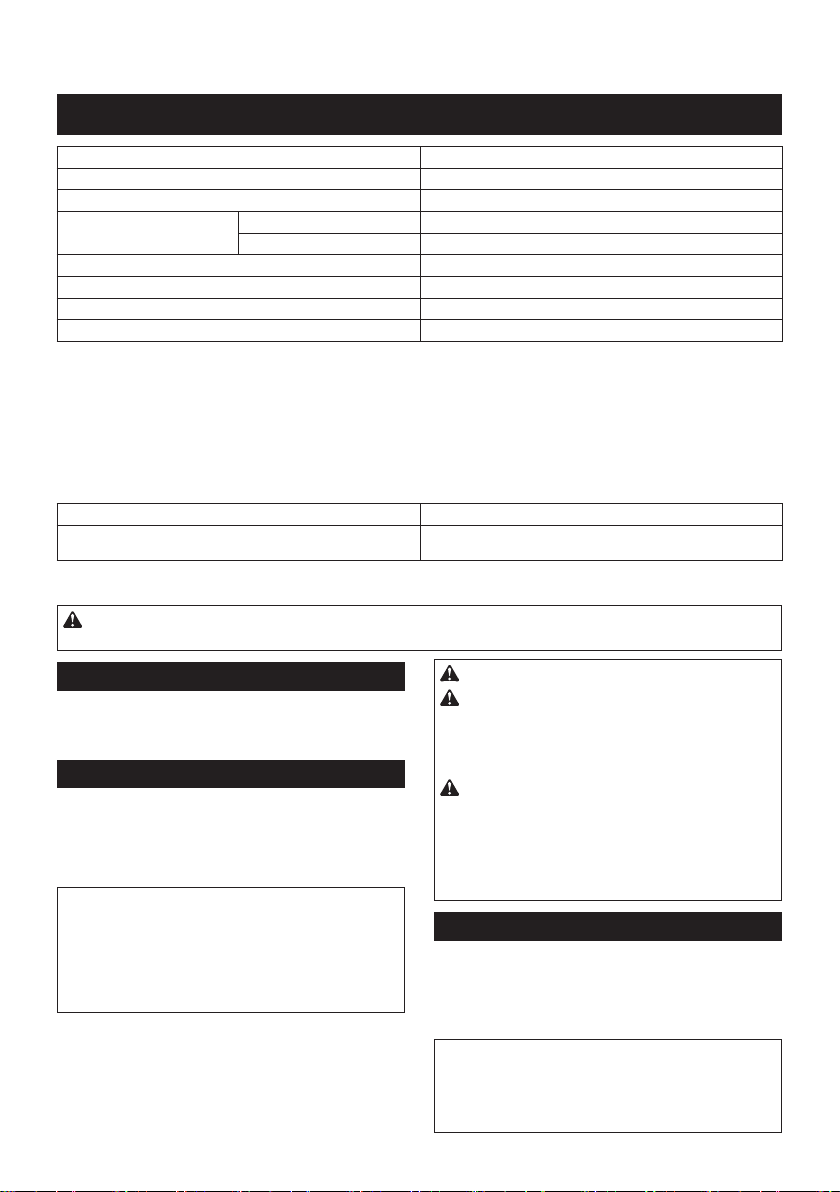

SPECIFICATIONS

Model: DCC500

Wheel diameter 125 mm

Max. wheel thickness 2.2 mm

Max. cutting capacities 0° bevel angle 40 mm

45° bevel angle 27 mm

Rated speed (n) 8,800 min-1

Overall length 283 mm *1

Rated voltage D.C. 18 V

Net weight 2.5 - 3.0 kg

*1. With battery cartridge (BL1860B).

• Duetoourcontinuingprogramofresearchanddevelopment,thespecicationshereinaresubjecttochange

without notice.

• Specicationsandbatterycartridgemaydierfromcountrytocountry.

• Theweightmaydierdependingontheattachment(s),includingthebatterycartridge.Thelightestandheavi-

est combinations, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

Battery cartridge BL1815N / BL1820B / BL1830B / BL1840B / BL1850B / BL1860B

Charger DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF /

DC18SH

• Some of the battery cartridges and chargers listed above may not be available depending on your region of

residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

andchargersmaycauseinjuryand/orre.

Intended use

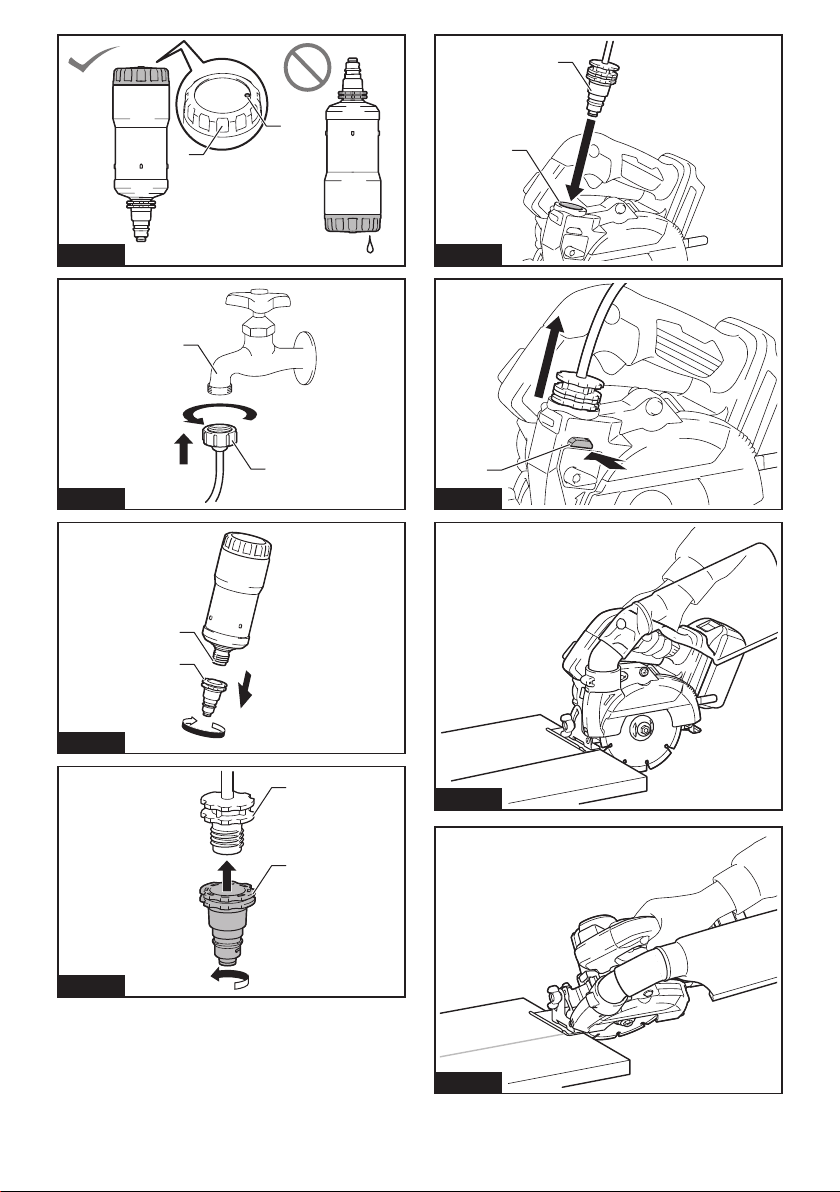

The tool is intended for cutting in brick and concrete

without the use of water. With appropriate Makita genu-

ine water supply cover, wet cutting can be performed.

Noise

The typical A-weighted noise level determined accord-

ing to EN60745-2-22:

Sound pressure level (LpA) : 96 dB(A)

Sound power level (LWA) : 107 dB (A)

Uncertainty (K) : 3 dB(A)

NOTE: The declared noise emission value(s) has

been measured in accordance with a standard test

method and may be used for comparing one tool with

another.

NOTE: The declared noise emission value(s)

may also be used in a preliminary assessment of

exposure.

WARNING: Wear ear protection.

WARNING: The noise emission during actual

use of the power tool can dier from the declared

value(s) depending on the ways in which the

tool is used especially what kind of workpiece is

processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

o and when it is running idle in addition to the

trigger time).

Vibration

The vibration total value (tri-axial vector sum) deter-

mined according to EN60745-2-22:

Work mode: concrete cutting

Vibration emission (ah) : 4.0 m/s2

Uncertainty (K) : 1.5 m/s2

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also

be used in a preliminary assessment of exposure.