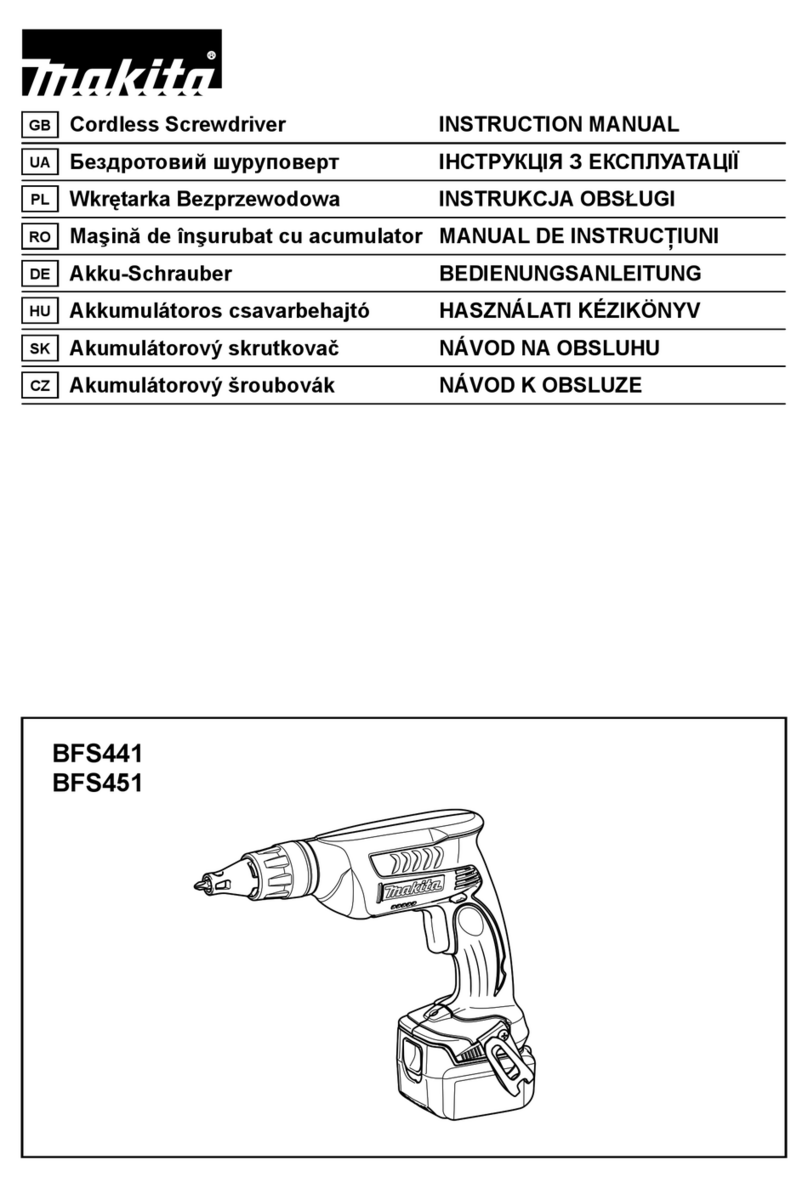

6ENGLISH

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also

be used in a preliminary assessment of exposure.

WARNING: The vibration emission during

declared value(s) depending on the ways in which

the tool is used especially what kind of workpiece

is processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

with this power tool. Failure to follow all instructions

serious injury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Cordless screwdriver safety

warnings

1. Hold the power tool by insulated gripping

surfaces, when performing an operation

where the fastener may contact hidden wiring.

Fasteners contacting a "live" wire may make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

2.

Be sure no one is below when using the tool in

high locations.

3.

4. Keep hands away from rotating parts.

5. Do not touch the bit or the workpiece immedi-

ately after operation; they may be extremely

hot and could burn your skin.

6. Always secure workpiece in a vise or similar

hold-down device.

7. Make sure there are no electrical cables, water

pipes, gas pipes etc. that could cause a hazard

if damaged by use of the tool.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product.

MISUSE or failure to follow the safety rules stated

in this instruction manual may cause serious

personal injury.

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble or tamper with the battery

cartridge.

or explosion.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

breakdown.

6. Do not store and use the tool and battery car-

tridge in locations where the temperature may

reach or exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

8. Do not nail, cut, crush, throw, drop the battery

cartridge, or hit against a hard object to the

battery cartridge. Such conduct may result in a

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on pack-

aging and labeling must be observed.

For preparation of the item being shipped, consult-

ing an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

battery in such a manner that it cannot move

around in the packaging.