Makita DHR182 User manual

Other Makita Power Tools manuals

Makita

Makita TM3000CX4 User manual

Makita

Makita HM1211B User manual

Makita

Makita HM1802 User manual

Makita

Makita 4604D User manual

Makita

Makita HR2652 User manual

Makita

Makita AN613 User manual

Makita

Makita 4351T User manual

Makita

Makita ST113D User manual

Makita

Makita HG 6020 User manual

Makita

Makita 4305 User manual

Makita

Makita 3707 User manual

Makita

Makita 9820-2 User manual

Makita

Makita AF201Z User manual

Makita

Makita DMP180 Operating instructions

Makita

Makita Makstar BSS610 User manual

Makita

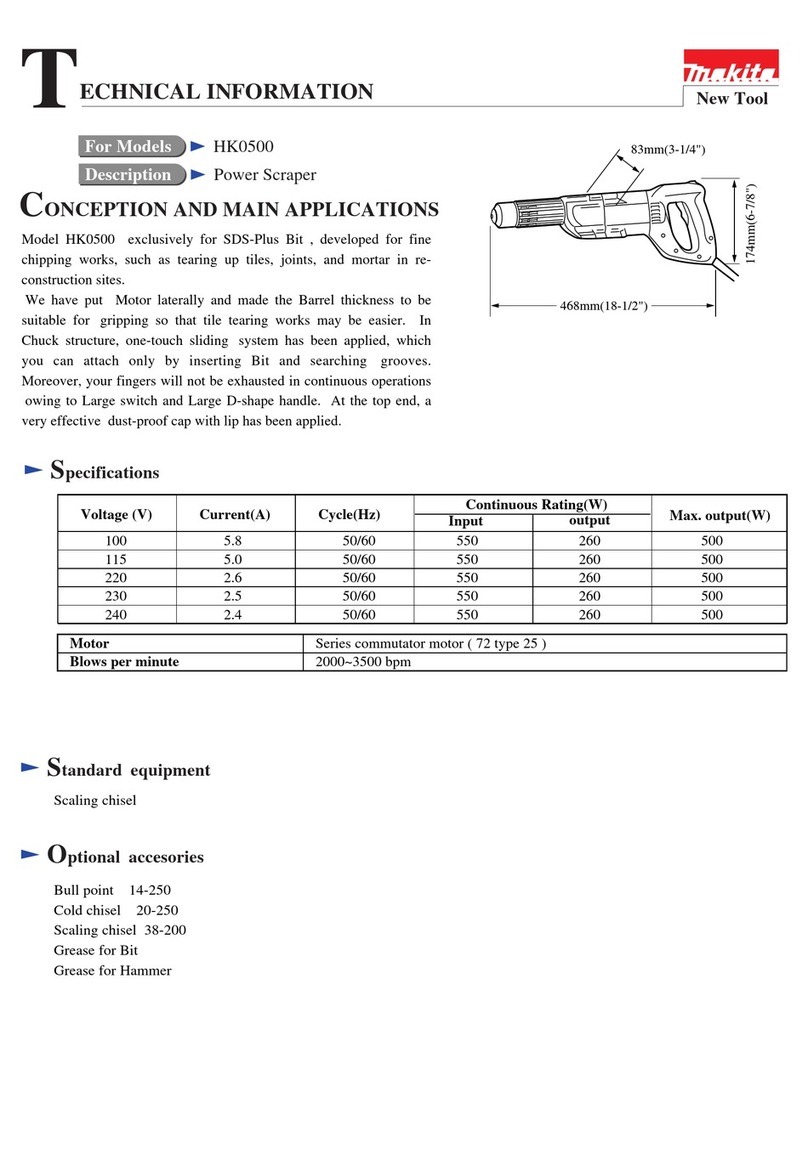

Makita HK0500 Manual

Makita

Makita TW004GZ01 User manual

Makita

Makita VR003G User manual

Makita

Makita BSS501 User manual

Makita

Makita DHR242ZJ User manual