Makita HK0500 Manual

Other Makita Power Tools manuals

Makita

Makita DTM40 User manual

Makita

Makita TM30D User manual

Makita

Makita DJS161 User manual

Makita

Makita BPJ180 User manual

Makita

Makita HM1213C User manual

Makita

Makita DUP362PT2 User manual

Makita

Makita 4326 User manual

Makita

Makita JN3200 User manual

Makita

Makita DTS131 User manual

Makita

Makita BTS130 User manual

Makita

Makita JS8000 User manual

Makita

Makita HS301D User manual

Makita

Makita DHR280 User manual

Makita

Makita BST221 User manual

Makita

Makita JS1300 User manual

Makita

Makita HM1304 User manual

Makita

Makita HK1820L User manual

Makita

Makita MP100D User manual

Makita

Makita DSC163ZK User manual

Makita

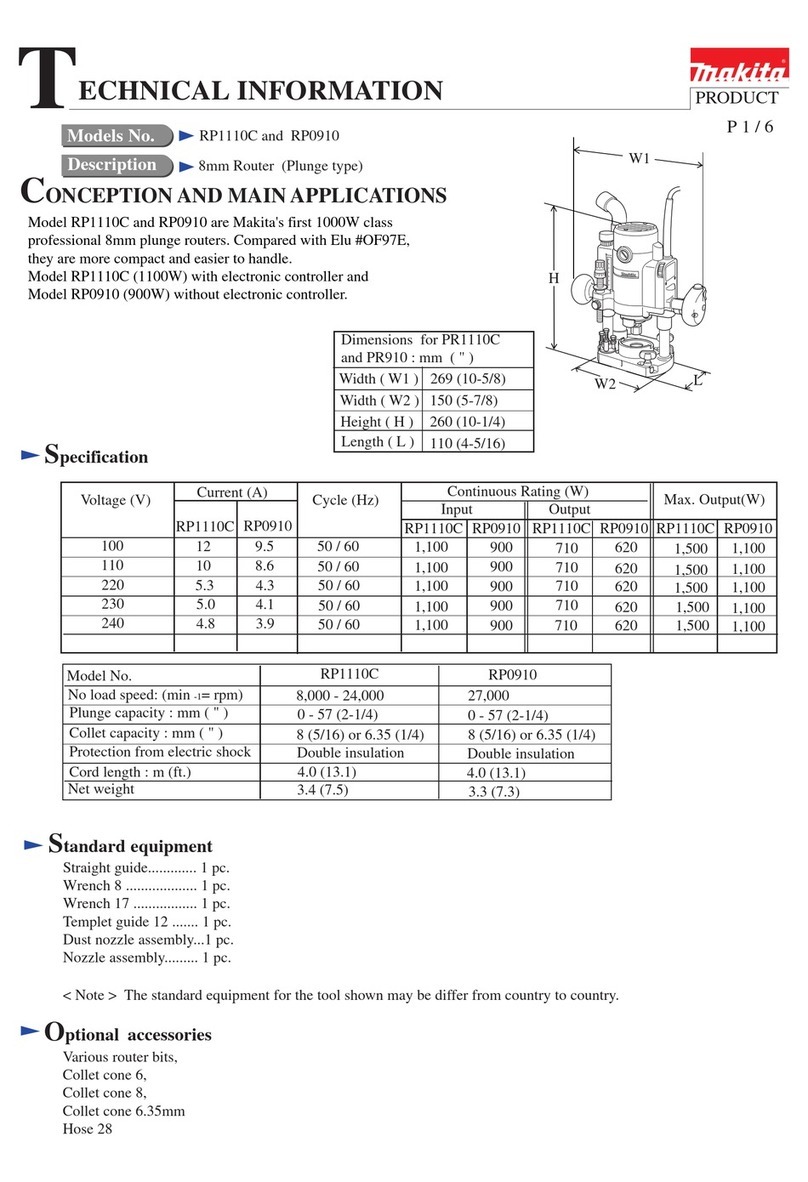

Makita RP1110C Manual