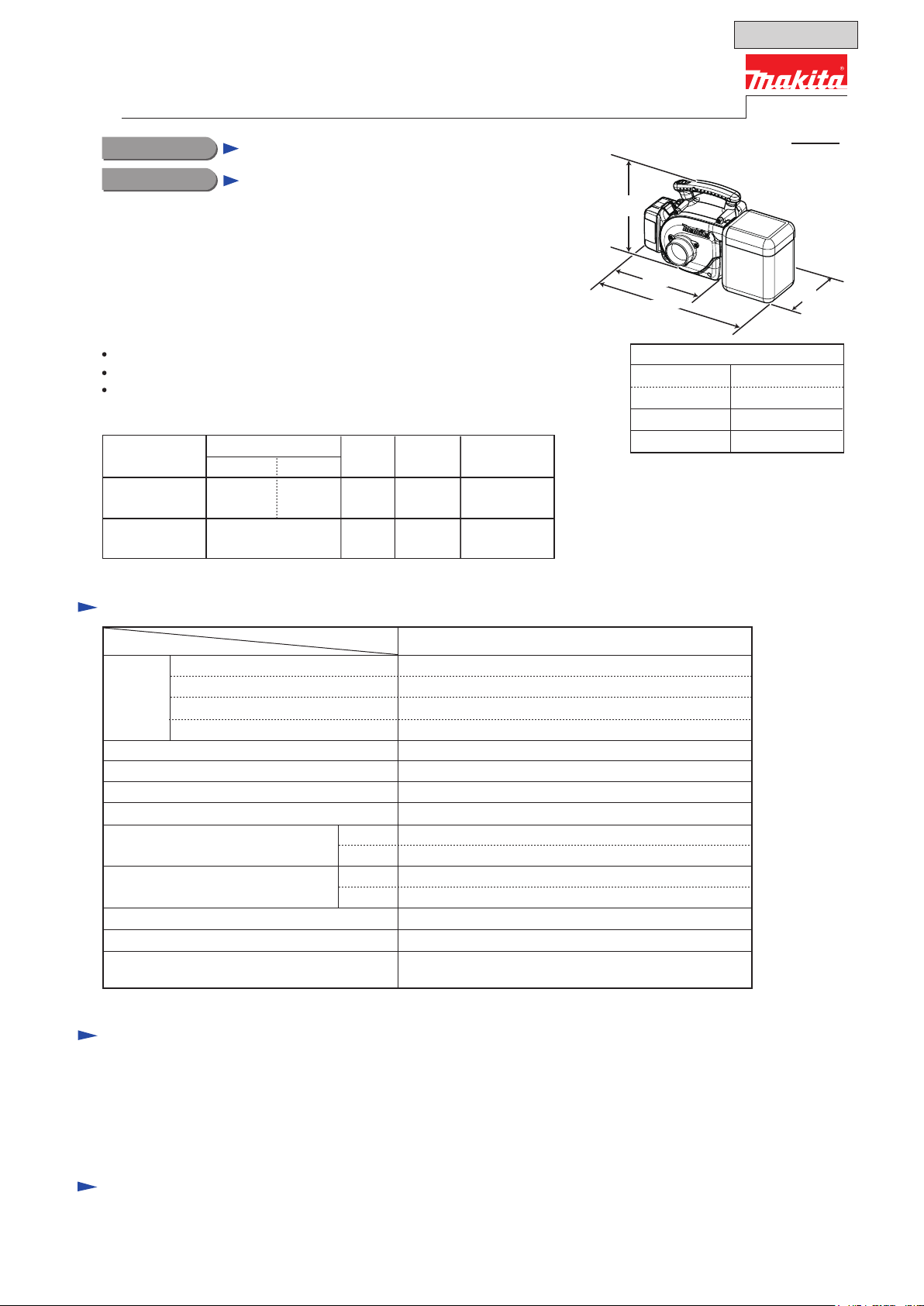

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 7

Specification

Standard equipment

Optional accessories

Note: The standard equipment may vary by country or model variation.

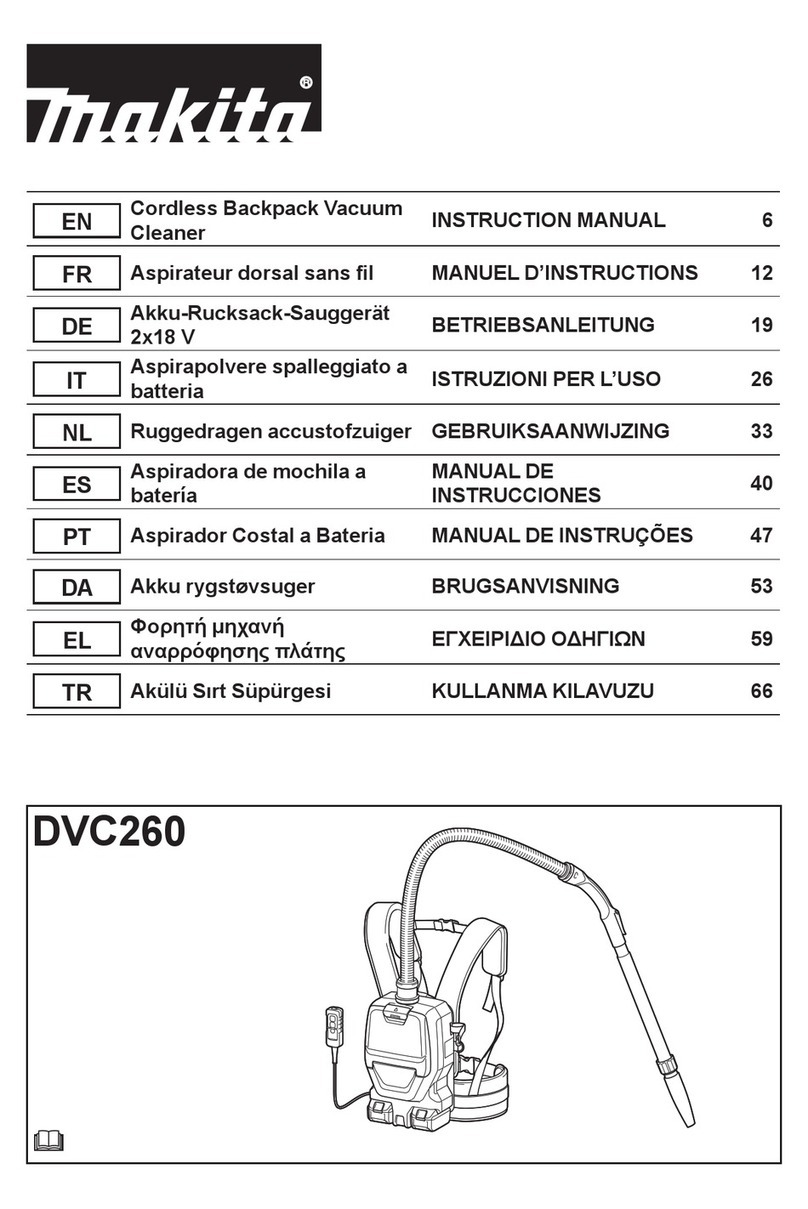

Model No.

Description

BVC350

18V Cordless Vacuum Cleaner

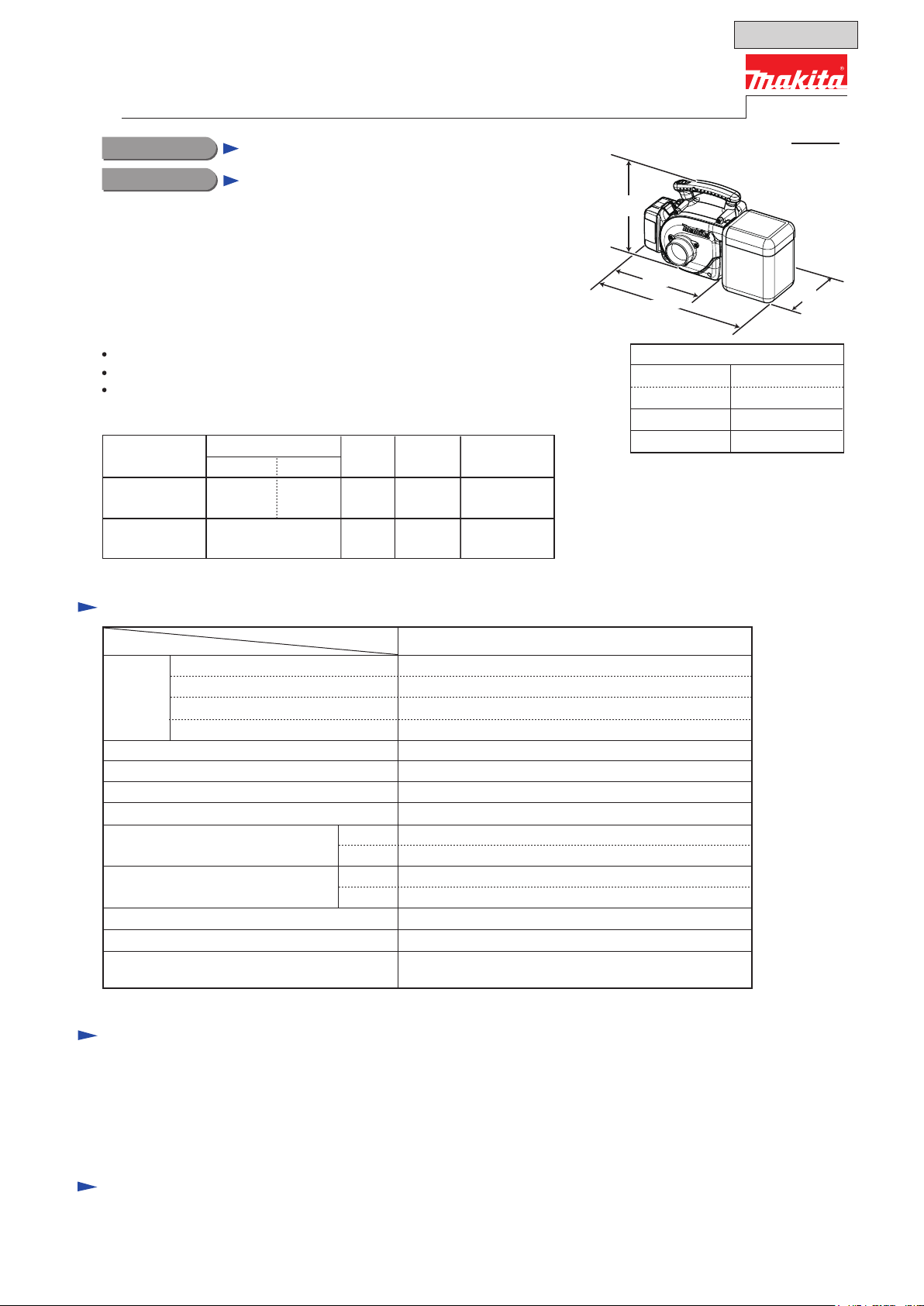

Dimensions*2: mm (")

Width (W)

Height (H)

Length (L1*3) 273 (10-3/4)

Length (L2*4) 403 (15-7/8)

195 (7-5/8)

226 (8-7/8)

Battery

Max. sealed suction: kPa (mmH2O)

Charging time (approx.): min.

Continuous run time (approx.)

on a single full battery charge: min.

Weight according to

EPTA-Procedure 01/2003*5: kg (lbs)

Dust bag capacity: L

Capacity: Ah

Cell

Voltage: V 18V

5.5 (560)

Air volume setting Yes (2 settings: High/ Low)

Max. air velocity: m/sec

3.0

Soft start Yes

13 (with Battery BL1830)

26 (with Battery BL1830)

2.2 (4.8)

1.3/ 3.0

Li-ion

3.4

15/ 22 with DC18RA

94

Max. air volume: m3/min.

*5 With Battery BL1815; without Nozzle assembly, Dust bag assembly, Hose complete

This product is available in the following variations:

BVC350RF

No

Model No. type quantity Charger

No

Battery

cover

Makita blue

DC18RA

BVC350Z NoNo

1BL1830 Makita blue

Housing

color

Battery

Nozzle assembly ........................................................... 1

Dust bag assembly (cloth) ............................................. 1

Hose complete ø28-2.5 (with Front cuff 22) ............... 1

Front cuff 38 .................................................................. 1

Shoulder belt ................................................................. 1

Battery BL1830

Battery BL1815

Fast charger DC18RA

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Model BVC350 is a Cordless vacuum cleaner powered by 18V

Li-ion battery; compatible with both 3.0Ah battery BL1830 and

1.3Ah battery BL1815.

Its main benefits are:

Cordless design for high portability

Large 3L dust bag capacity

High/Low air volume settings to suit your application

High

Low

Suction power: W 50

15

High

Low

The models also include the accessories listed below in "Standard equipment".

Specification Model BVC350

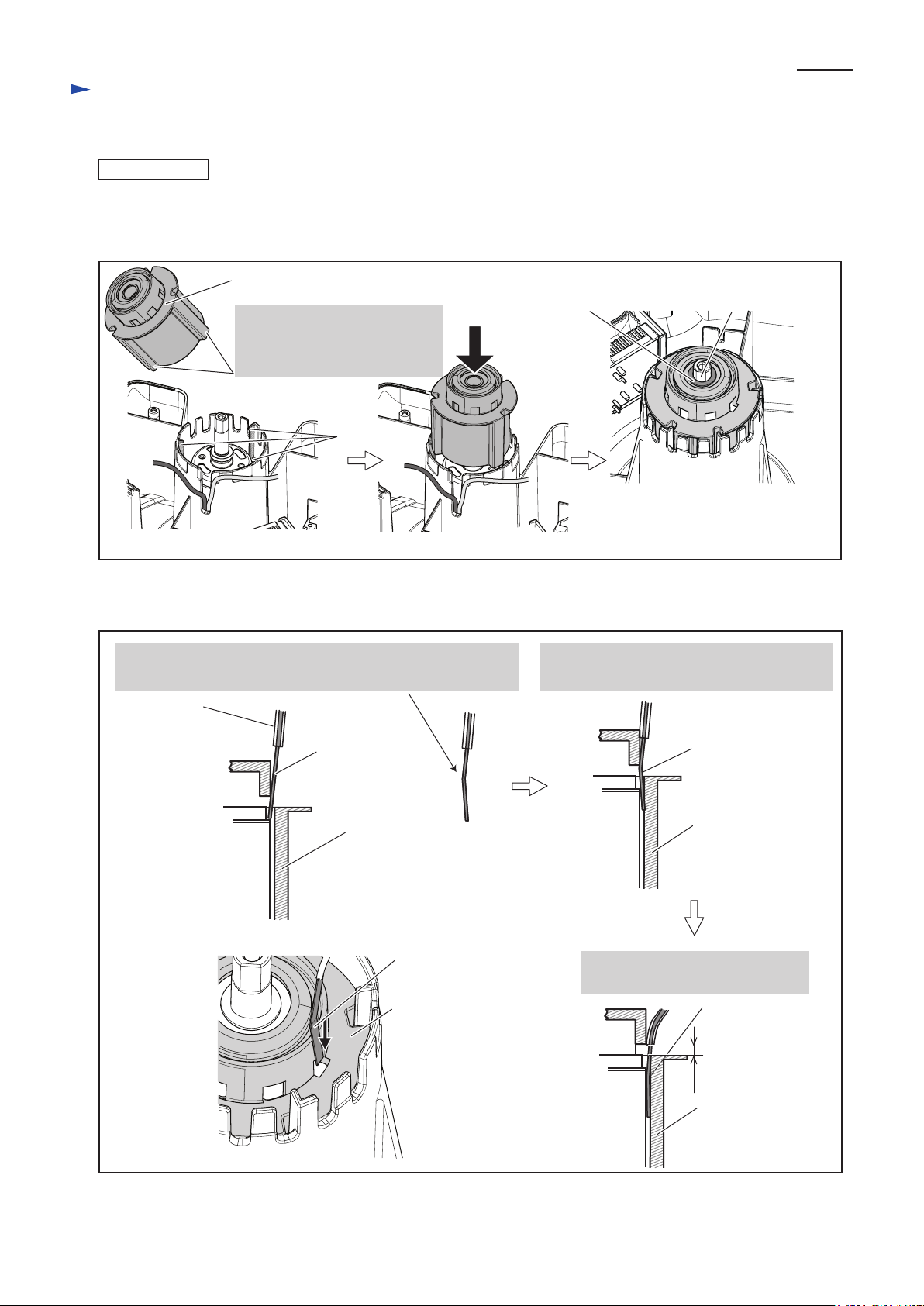

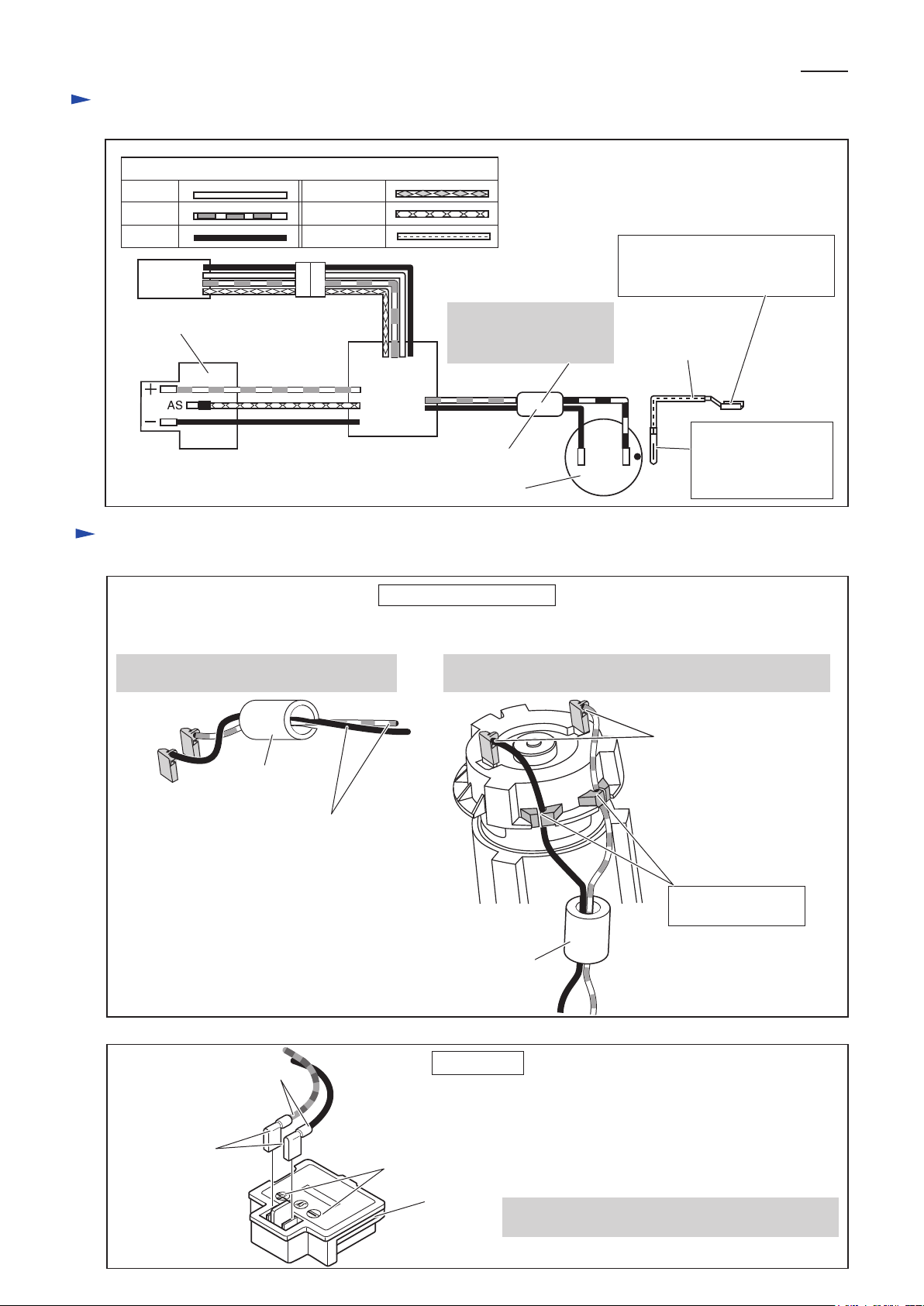

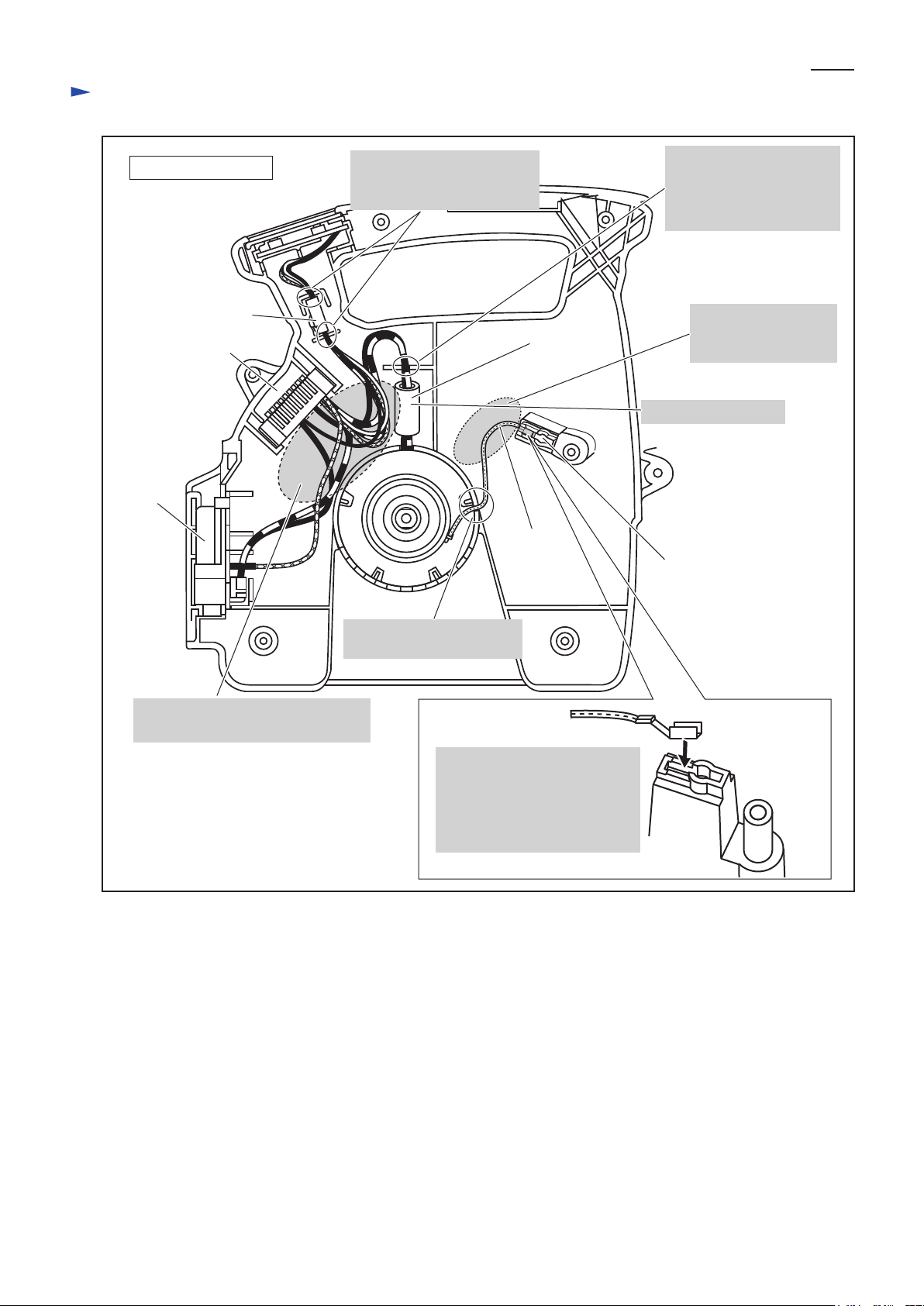

TECHNICAL INFORMATION

*2 With Battery BL1830

*3 L1: without Dust bag assembly

*4 L2: with Dust bag assembly

L1

L2

H

W

OFFICIAL USE

for ASC & Sales Shop