Full Body Harness Instruction Manual

Materials and Construction

Webbing Materials

•Constructed with high tenacity polyester; breaking strength >5000 lbs tensile strength

•Constructed with Aramid, breaking strength > 5000 lbs tensile strength

Pad and Label Cover Materials

•All outer fabric: Nomex and Kevlar blend fabric

•Fire Resistant hook and loop fasteners

•Nylon and Polyester blend

Connector Materials

•Galvanized Steel

Purpose

Malta Dynamics Full Body Harnesses are Class 3 full body harnesses designed for an array of full-

body applications. Such full body harnesses are the only form of body wear acceptable for fall arrest.

Full-body harnesses may also be used for positioning, travel restraint and rescue.Malta Dynamics

harnesses are designed and tested to comply with applicable OSHA and ANSI standards for fall

protection equipment. When used as a component in a personal fall arrest system, or a personal

restraint system, Malta Dynamics full body harnesses comply with OSHA directives for fall protection

wear. Full body harnesses help absorb the impact forces and keep the body upright should a fall

occur.

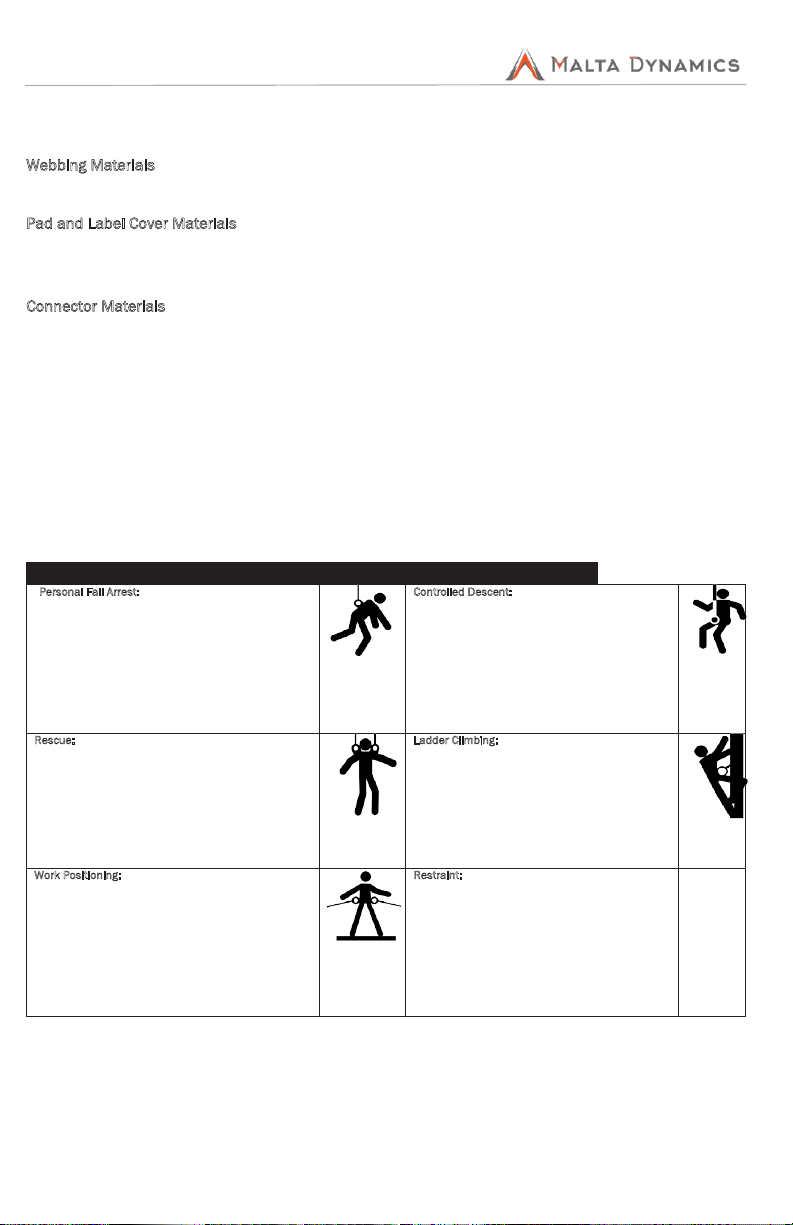

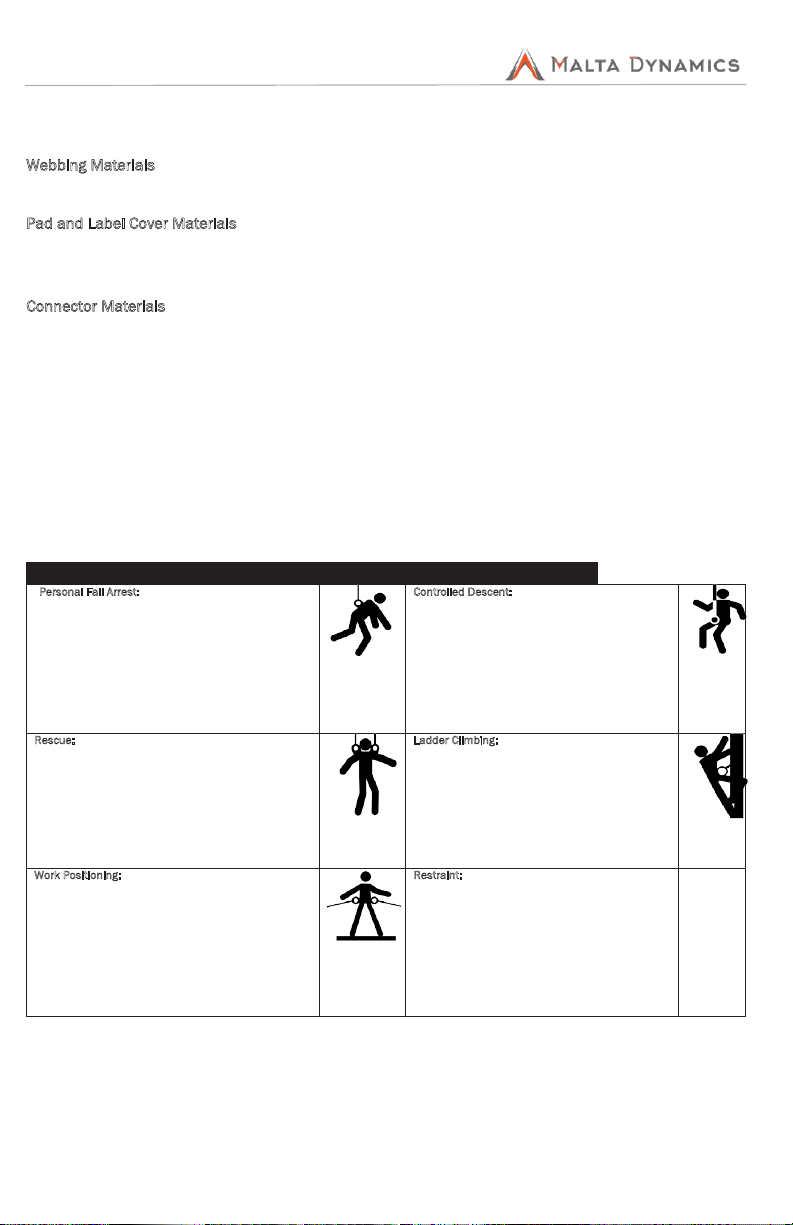

Illustration 1: Applications

The full body harness is used as a component of a

personal fall arrest system. Personal fall arrest

systems typically include a full body harness and a

connecting subsystem (energy absorbing lanyard).

Maximum arresting force must not exceed 900 lbs (4

kN), for fall arrest applications connect the fall arrest

subsystem (example: lanyard, SRL, energy absorber,

etc.) to the D-ring or attachment element on your

back, between your shoulder blades.

For controlled descent applications, full body

harnesses equipped with a single sternal level D-

ring, one or two frontal mounted D-rings, or a pair

of connectors originating below the waist (such as

a seat sling) may be used for connection to a

descender or evacuation system.

The full body harness is used as a component of a

rescue system. Rescue systems are configured

depending on the type of rescue. For limited access

(confined space) applications, harnesses equipped

with D-rings on the shoulders may be used for entry

and egress into confined spaces where worker profile

is an issue.

The full body harness is used as a component of a

climbing system to prevent the user from falling

when climbing a ladder or other climbing structure.

Climbing systems typically include a full body

harness, vertical cable or rail attached to the

structure, and climbing sleeve. For ladder climbing

applications, harnesses equipped with a frontal D-

ring in the sternal location may be used for fall

arrest on fixed ladder climbing systems.

The full body harness is used as a component of a

work positioning system to support the user at a work

position. Work positioning systems typically include a

full body harness, positioning lanyard, and a back-up

personal fall arrest system. For work positioning

applications, connect the work positioning subsystem

(example: lanyard, Y-lanyard, etc.) to the lower (hip

level) side or belt mounted work positioning

attachment anchorage elements (D-rings). Never use

these connection points for fall arrest.

The full body harness is used as a component of a

restraint system to prevent the user from reaching

a fall hazard. Restraint systems typically include a

full body harness and a lanyard or restraint line.

2 19

Full Body Harness Instruction Manual

chest strap to slide up and possibly choke the user during a fall, extraction, suspension, etc.

The competent person should consider Full Body Harness models with a fixed sternal

attachment for these applications.

12. Frontal –The frontal attachment serves as a ladder climbing connection for guided type fall

arresters where there is no chance to fall in a direction other than feet first, or may be used for

work positioning. Supporting the user, post fall or during work positioning, by the frontal

attachment will result in a sitting body position, with the upper torso upright, with weight

concentrated on the thighs and buttocks. When supported by the frontal attachment the

design of the Full Body Harness shall direct load directly around the thighs and under the

buttocks by means of the sub-pelvic strap. If the frontal attachment is used for fall arrest, the

competent person evaluating the application should take measures to ensure that a fall can

only occur feet first. This may include limiting the allowable free fall distance.

13. Shoulder –The shoulder attachment elements shall be used as a pair, and are an

acceptable attachment for rescue and entry/retrieval. The shoulder attachment elements

shall not be used for fall arrest. It is recommended that the shoulder attachment elements

be used in conjunction with a yoke which incorporates a spreader element to keep the Full

Body Harness shoulder straps separate.

14. Waist, Rear –The waist, rear attachment shall be used solely for travel restraint. The

waist, rear attachment element shall not be used for fall arrest. Under no circumstances is

it acceptable to use the waist, rear attachment for purposes other than travel restraint. The

waist, rear attachment shall only be subjected to minimal loading through the waist of the

user, and shall never be used to support the full weight of the user.

15. Hip –The hip attachment elements shall be used as a pair, and shall be used solely for

work positioning. The hip attachment elements shall not be used for fall arrest. Hip

attachments are often used for work positioning by arborists, utility workers climbing poles

and construction workers tying rebar and climbing on form walls. Users are cautioned

against using the hip attachment elements (or any other rigid point on the Full Body

Harness) to store the unused end of a fall arrest lanyard, as this may cause a tripping

hazard, or, in the case multiple leg lanyards, could cause adverse loading to the Full Body

Harness and the wearer through the unused portion of the lanyard.

16. Suspension seat –The suspension seat attachment elements shall be used as a pair,

and shall be used solely for work positioning. The suspension seat attachment elements

shall not be used for fall arrest. Suspension seat attachments are often used for prolonged

work activities where the user is suspended, allowing the user to sit on the suspension

seat formed between the two attachment elements. An example of this use would be

window washers on large buildings.

User Inspection, Maintenance and Storage of Equipment

Users of personal fall arrest systems shall, at a minimum, comply with all manufacturer

instructions regarding the inspection, maintenance and storage of the equipment. The user’s

organization shall retain the manufacturer’s instructions and make them readily available to all

users. See ANSI/ASSE Z359.2, Minimum Requirements for a Comprehensive Managed Fall

Protection Program, regarding user inspection, maintenance and storage of equipment.

1. In addition to the inspection requirements set forth in the manufacturer’s instructions, the