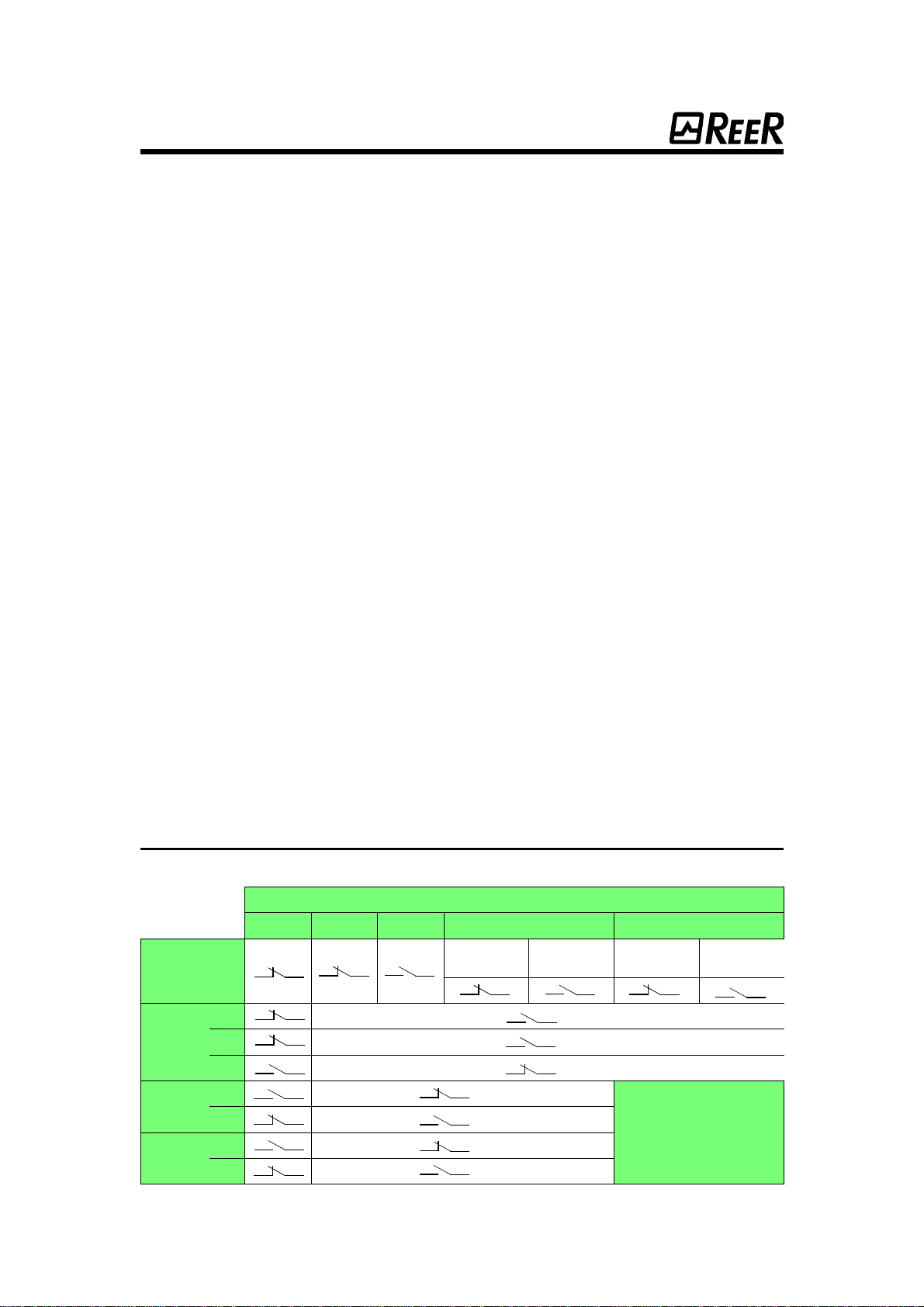

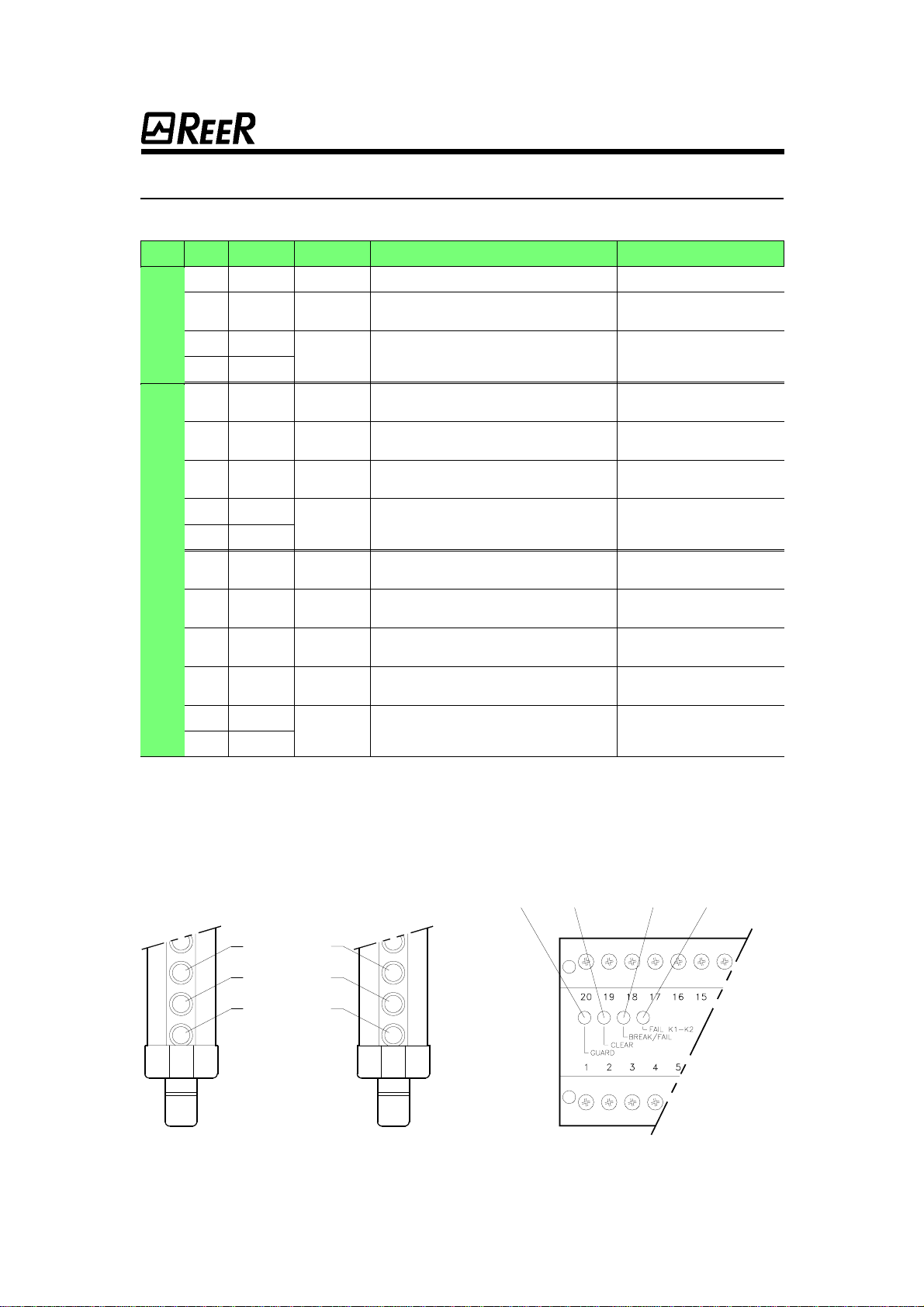

TEST SEQUENCE AND CONTROLS

TEST SEQUENCE AND CONTROLSTEST SEQUENCE AND CONTROLS

TEST SEQUENCE AND CONTROLS

Optical scanning circuitry.

Optical scanning circuitry.Optical scanning circuitry.

Optical scanning circuitry.

The scanning circuitry of ARGOLUX AS safety barrier is based upon a

self-checking principle which permanently controls its correct operation.

Particularly,thesystemcontrolsthemultiplexsignalontheemitterside,and

measures theIR light pulse period emitted foreach beam of the curtain.

The reversed operations are carried out on the receiver side where the

system controls the demultiplex signals and recognize the infrared light

pulse thanks to the measurement of the caught light period.

An accurate synchronisation enables this identification and avoids taking

into account possible infrared disturbances.

If an unwanted condition occurs during the IR light beam transmission (an

object is in the detection field or a failure appears), the receiver sends a

command signal to the control unit which de-energizes its relays and

remains in the alarm condition until the fault condition is removed.

Output circuitry.

Output circuitry.Output circuitry.

Output circuitry.

The control unit AU S3 controls the correct operation of the both emitter

and the receiver units thanks to its electrical connection with the receiver

ASR. The receiver provides thecontrol unitwith a signal through its unique

relay output. As mentioned in the EN 61496-1 norm, the test facility

provided with type 2 optoelectronic protective devices is partly designed to

checkthe correct operation ofthis relayoutput.

Other operations are checked during the test to ensure the integrity of the

system:

•The correct interlinking of the test sequence and the effective reset

of the system (test command);

•The reaction time of the two inner relays A and B (safety relays with

guided contacts) and the reaction time of the two external relays

K1 and K2, if auxiliary contacts of K1 and K2 are connected to

terminals 5 and 6 (use only safety relays with guided contacts);

•The inner command of A and B relays. A possible failure of one

component of the output circuitry can only be detected during the

test phase, and therefore the control unit de-energizes its relays

only when the next test is applied. This is also true for external

relays K1 and K2 by means of the feedback control (see below).

Test input.

Test input.Test input.

Test input.

The ARGOLUX AS curtain is a type 2 opto-electronic protective device

designed according to the EN 61496-1 and prEN 61496-2 European

Norm.Its safeguardingfunction isbasedupon aperiodicperformancetest

initiated by the machine.

7

77

7