McHale F5000 Installation instructions

Other McHale Farm Equipment manuals

McHale

McHale Fusion 2 Assembly instructions

McHale

McHale 6272 Installation instructions

McHale

McHale F5400 Assembly instructions

McHale

McHale 994BS User manual

McHale

McHale F550 Assembly instructions

McHale

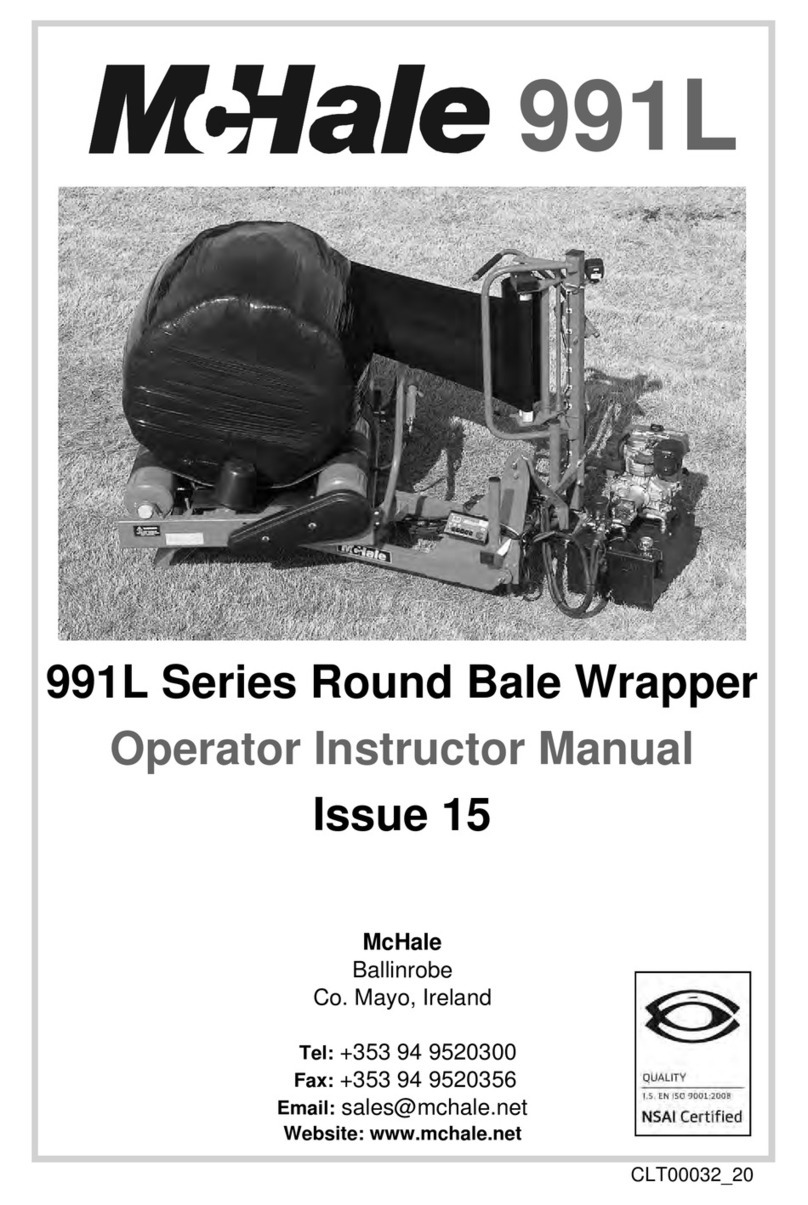

McHale 991L Series User manual

McHale

McHale Twiner Assembly instructions

McHale

McHale Issue 5 Assembly instructions

McHale

McHale HS2000 User manual

McHale

McHale Fusion 2 Operating manual

McHale

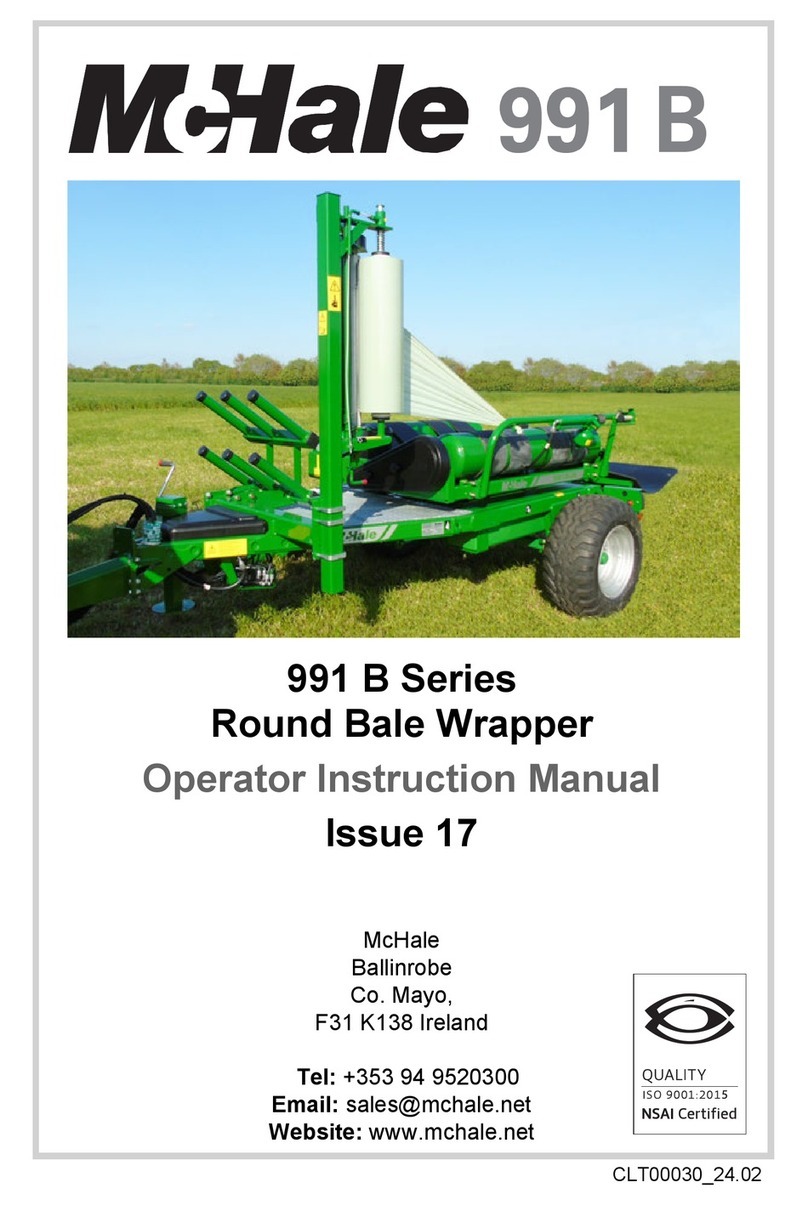

McHale 991B Series Assembly instructions

McHale

McHale V Series Assembly instructions

McHale

McHale Orbital Assembly instructions

McHale

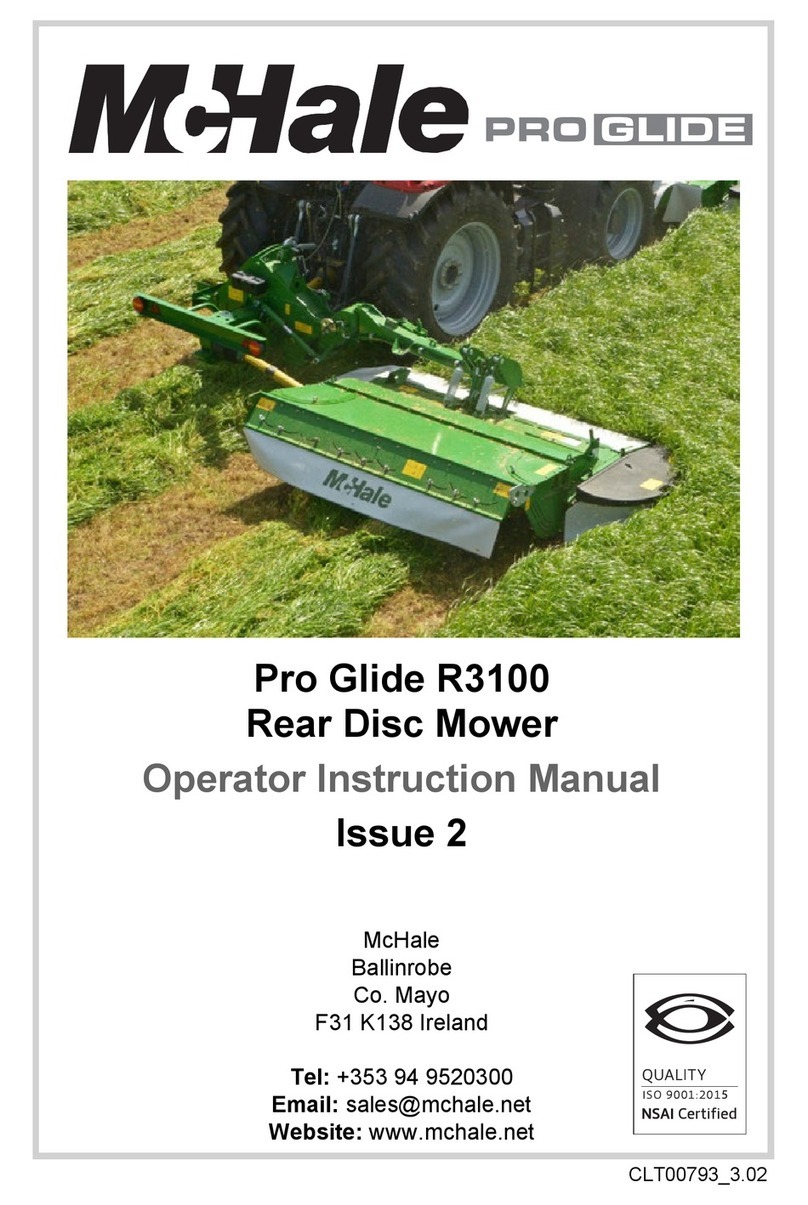

McHale Pro Glide R3100 Assembly instructions

McHale

McHale 991 Assembly instructions

McHale

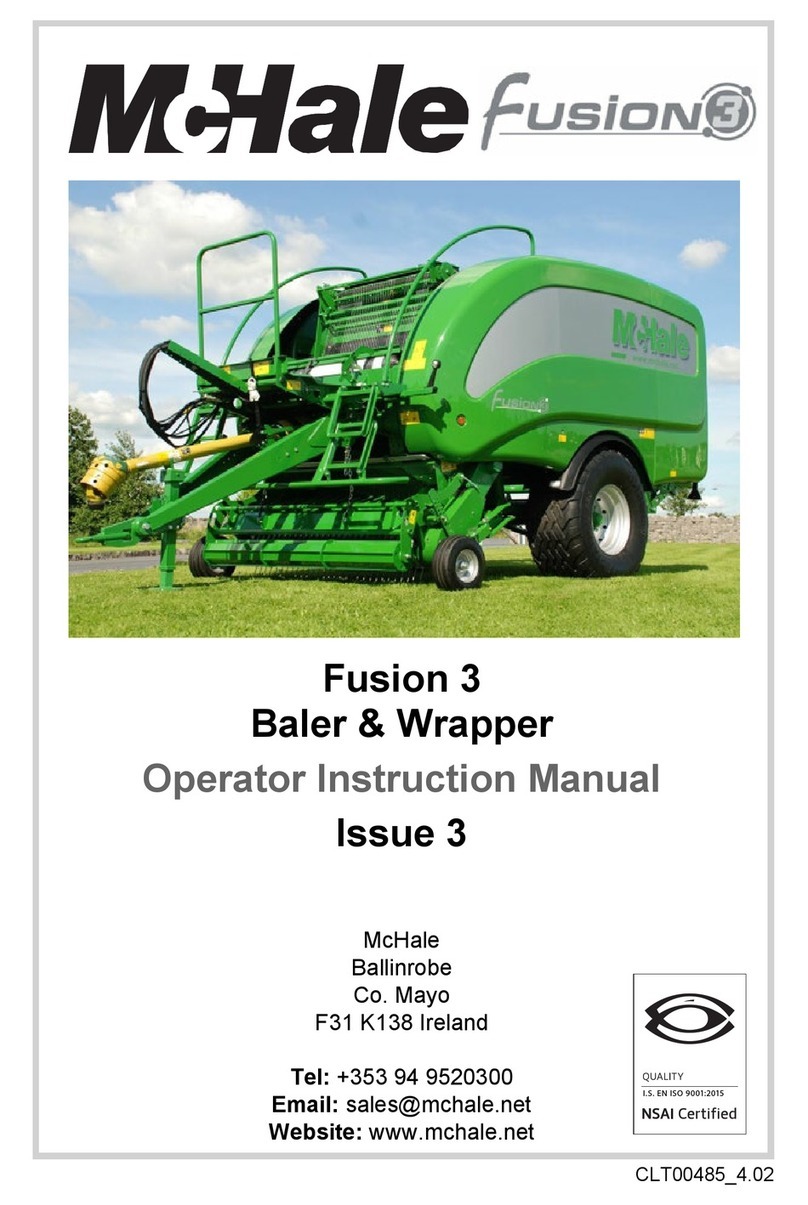

McHale Fusion 3 Assembly instructions

McHale

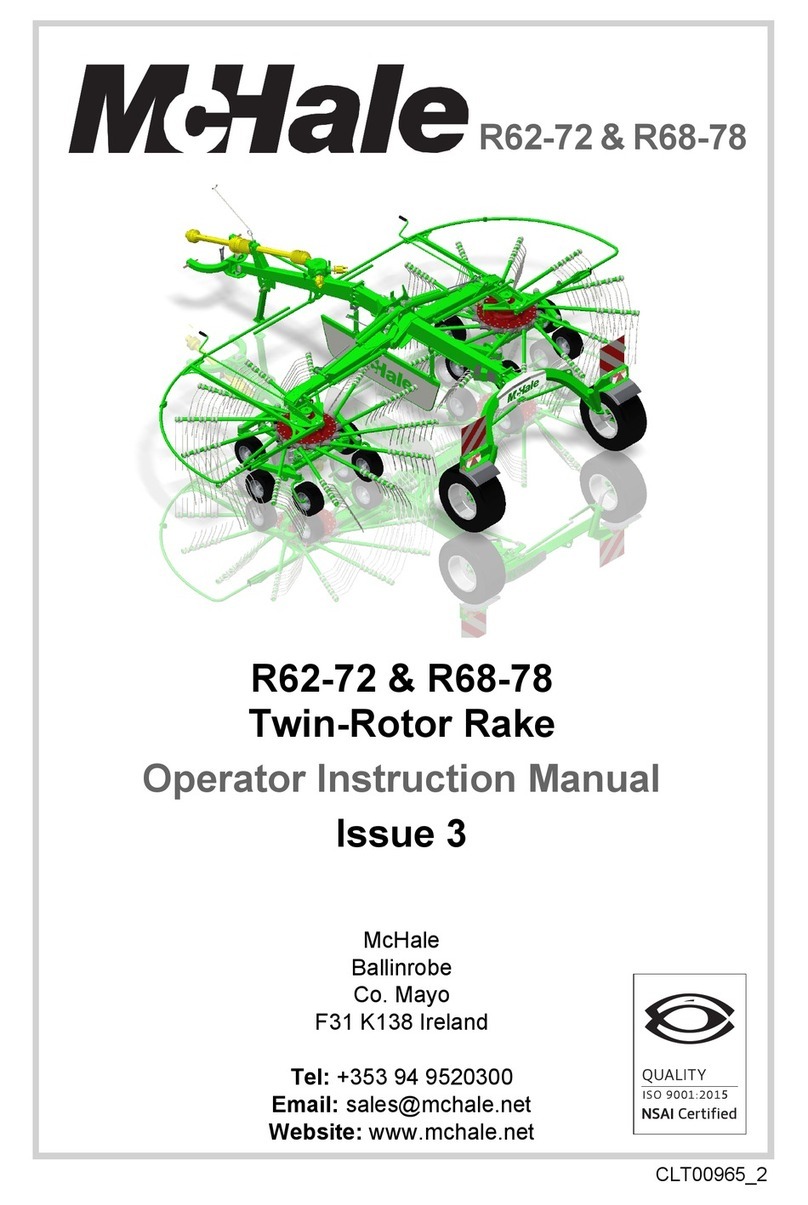

McHale R62-72 Assembly instructions

McHale

McHale W2020 Assembly instructions

McHale

McHale F5500 Assembly instructions

McHale

McHale Fusion 3 User manual