Contents

6

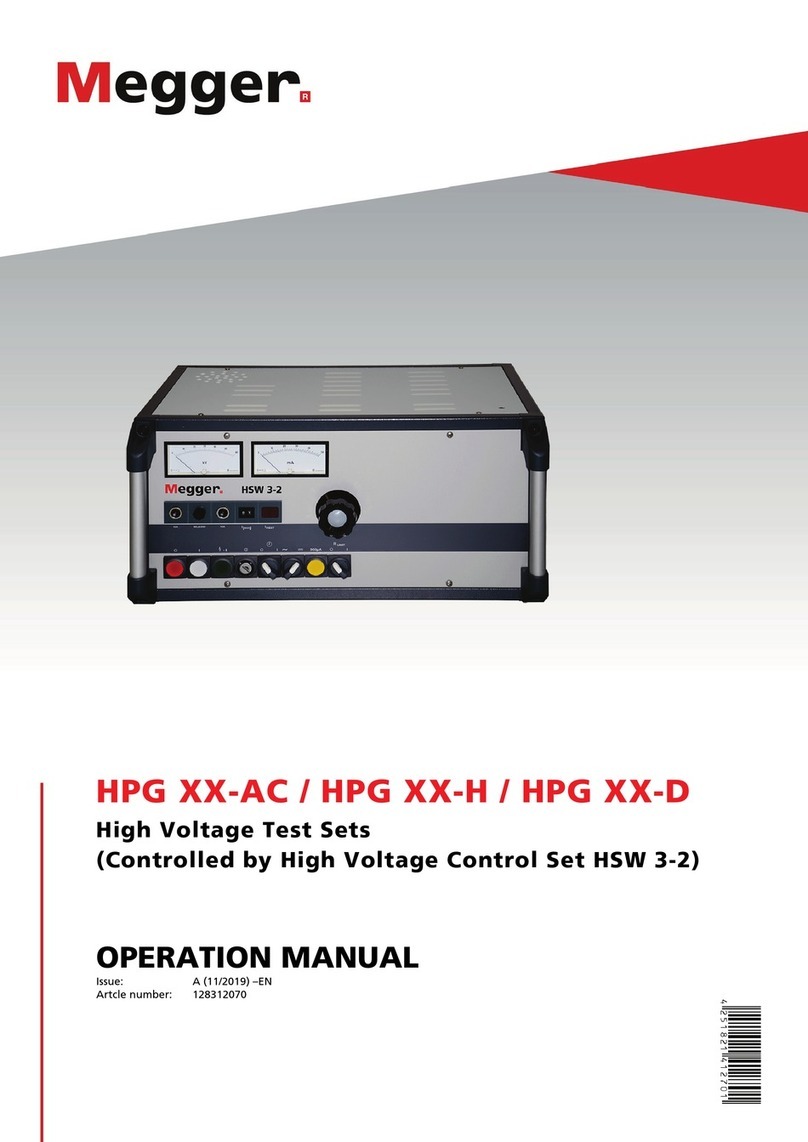

Contents

Consultation with Megger...............................................................................................4

Terms of Warranty ...........................................................................................................5

Contents ...........................................................................................................................6

1Safety Instructions ...........................................................................................7

1.1 General Notes ....................................................................................................7

1.2 General Safety Instructions and Warnings.........................................................8

2Technical Description ....................................................................................10

2.1 System Description ..........................................................................................10

2.2 Technical Data .................................................................................................11

2.3 Load Diagram ...................................................................................................13

2.4 Scope of Delivery and Accessories..................................................................14

2.5 Display and Controls ........................................................................................15

2.6 Connection Elements .......................................................................................16

3Commissioning ..............................................................................................18

3.1 Electrical Connection........................................................................................18

3.1.1 Normal Connection...........................................................................................19

3.1.2 Connection via VLF CR Test Boost (Optional).................................................21

3.1.3 Use of an External Safety Device (Optional)....................................................23

3.2 Switching On ....................................................................................................24

4Operation ........................................................................................................25

4.1 Safety Circuit ....................................................................................................25

4.2 General Operation............................................................................................27

4.3 System Menu ...................................................................................................30

5Operating Modes ............................................................................................31

5.1 Cable Testing ...................................................................................................31

5.2 Sheath Test and Sheath Fault Pinpointing.......................................................35

5.2.1 Sheath Test ......................................................................................................37

5.2.2 Sheath Fault Pinpointing ..................................................................................38

5.3 VLF Tan Delta Loss Factor Measurement (Optional) ......................................39

5.3.1 Preparing for Measurement..............................................................................39

5.3.2 Course of the Measurement.............................................................................41

5.3.3 Evaluation of the Test Results .........................................................................43

5.3.3.1 Automatic Evaluation........................................................................................43

5.3.3.2 Manual Evaluation............................................................................................44

6Completing the Work .....................................................................................47

7Combination with other test systems ..........................................................48

8Maintenance and Repair ................................................................................49