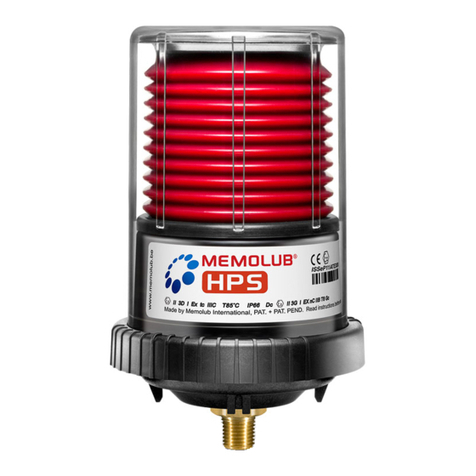

MEMOLUB®HPS User’s Guide Page 1 of 39 PLI, LLC

TABLE OF CONTENTS

1THE MEMOLUB®HPS ...................................................................................................................................... 3

1.1 OVERVIEW ...................................................................................................................................................... 3

1.2 THE MEMO.................................................................................................................................................... 4

1.2.1 Description............................................................................................................................................. 4

1.2.2 Volumetric Setting of the MEMO ........................................................................................................... 4

1.2.3 Frequency Setting of the MEMO............................................................................................................ 4

1.3 THE LUBRICATOR BODY ................................................................................................................................. 5

1.3.1 Description............................................................................................................................................. 5

1.3.2 Function ................................................................................................................................................. 5

1.4 LUBRICANT CARTRIDGES AND BATTERY PACKS............................................................................................. 6

1.4.1 Lubricant Cartridges.............................................................................................................................. 6

1.4.2 Battery Packs.......................................................................................................................................... 6

1.4.3 Stocking .................................................................................................................................................. 6

1.5 MEMOLUB®EX ........................................................................................................................................... 6

2THE MULTI-POINT LUBRICATION SYSTEM............................................................................................ 7

2.1 FUNCTION ....................................................................................................................................................... 7

2.2 DISTRIBUTION BLOCKS ................................................................................................................................... 7

2.3 COUPLER BRIDGING ELEMENTS ...................................................................................................................... 8

3THE 2-POINT SPLITTER (ALSO KNOWN AS "SPLITTER-MEMO") .................................................... 8

3.1 DESCRIPTION .................................................................................................................................................. 8

3.2 HOW IT WORKS .............................................................................................................................................. 9

3.3 RETROFITTING A MEMOLUB®...................................................................................................................... 9

4THE MEMOLUB®HPS WITH EXTERNAL POWER CONTROL OR SUPPLY ...................................... 9

4.1 THE MEMOLUB®EPC VERSION................................................................................................................... 9

4.2 THE MEMOLUB®EPS: 4.5VDC, 12VDC &24VDC POWERED ................................................................. 10

4.3 THE MEMOLUB®24VDC PLC CONTROLLED VERSION.............................................................................. 11

5ACCESSORIES ................................................................................................................................................. 12

5.1 TUBING ......................................................................................................................................................... 12

5.2 TABLE OF RECOMMENDED PIPE AND TUBING LENGTHS................................................................................ 13

5.3 FITTINGS ....................................................................................................................................................... 13

6INSTALLATION ............................................................................................................................................... 14

6.1 INSTALLING THE MEMO .............................................................................................................................. 14

6.2 OPENING AND CLOSING THE MEMOLUB®HPS .......................................................................................... 14

6.2.1 Opening the MEMOLUB® HPS ................................................................................................................. 14

6.2.2 Closing the MEMOLUB® HPS................................................................................................................... 14

6.3 INSTALLING A GREASE CARTRIDGE .............................................................................................................. 14

6.4 INSTALLING AN OIL CARTRIDGE ................................................................................................................... 16

6.5 TESTING THE MEMOLUB®HPS (CHECK FUNCTION).................................................................................. 16

6.6 MOUNTING THE MEMOLUB®HPS ONTO THE MEMO ................................................................................ 17

6.7 TESTING THE MEMOLUB®HPS (WHILE MOUNTED) .................................................................................. 17

6.8 MAINTENANCE.............................................................................................................................................. 17

7 MOUNTING DO’S AND DON’TS............................................................................................................... 17

7.1 GENERAL ...................................................................................................................................................... 17

7.2 SINGLE-POINT INSTALLATION....................................................................................................................... 17

7.2.1 Direct Installation ................................................................................................................................ 17