4

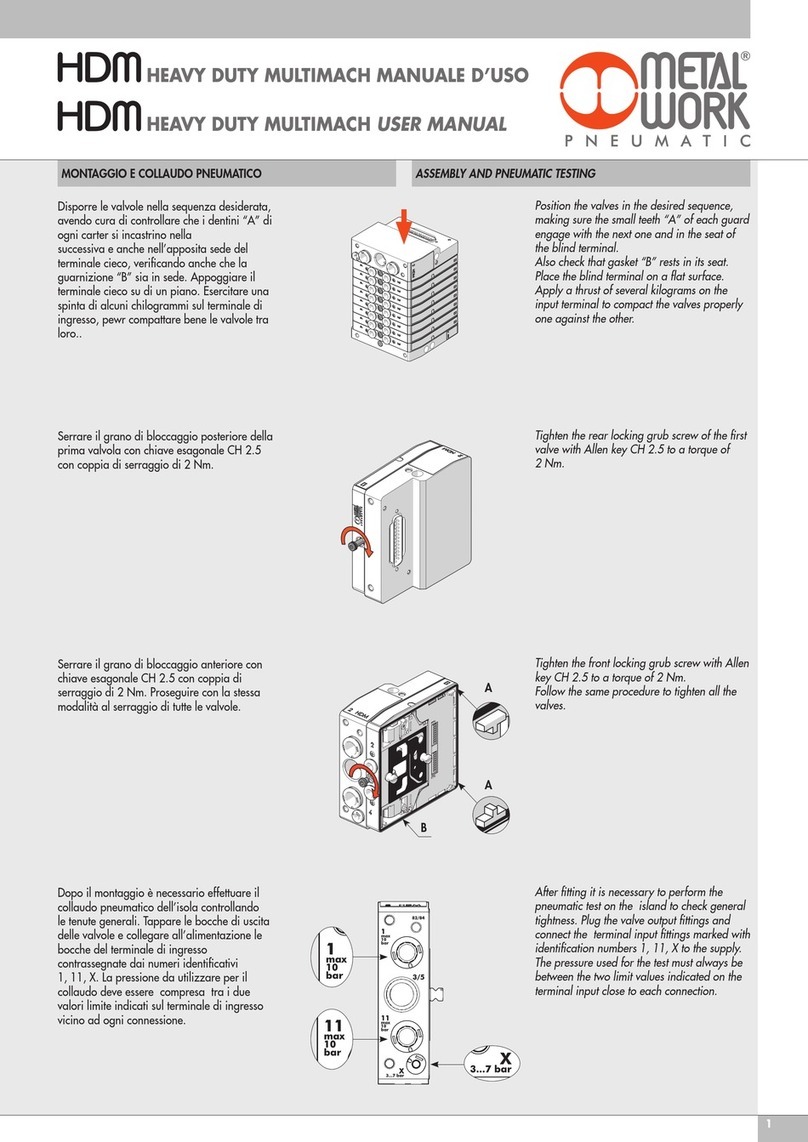

Appoggiare l’isola su una superficie piana, inserire il terminale cieco

e serrare le tre viti con una coppia di 2 Nm. Nelle versioni con scheda

elettronica (C2-C3) fare attenzione all’allineamento delle schede.

NON FORZARE.

Place the island on a flat surface, insert the blind end plate and tighten

the three screws at a torque of 2 Nm. In the versions with electronic

board (C2-C3), make sure the boards are properly aligned.

DO NOT FORCE.

Dopo aver verificato il corretto posizionamento delle guarnizioni,

montare le valvole e avvitare le viti con cacciavite a croce PH1, con una

coppia di 1.1 ÷ 1.3 Nm. Serrare prima la vita A e poi la B.

After checking that the seals are positioned properly, install the valves

and tighten the screws with a cross screwdriver PH1 at a torque of

1.1 - 1.3 Nm. First tighten screw A and then screw B.

Sull’ultima base svitare i tre grani M4 f.

Serrare i tre tiranti g con chiave esagonale da 4 mm applicando una

coppia di 2 Nm.

NB: per un allineamento ottimale delle schede è consigliabile

assemblare le basi SENZA la valvole montate.

Unscrew the three M4 grub screws on the end base f.

Tighten the three tie rods g using a 4 mm socket wrench at a torque of

2 Nm.

N.B. For the optimal alignment of the boards, it is advisable to install

the bases WITHOUT the valves assembled.

A

B

Lubrificare il filetto

lubricate the thread