6

www.metcal.com

9. WARRANTY

Please visit OK International's products web page (www.metcal.com) where you will find

available information on systems, tips, accessories, technical notes, and more. You may also

contact your local OK International representative for pricing and availability.

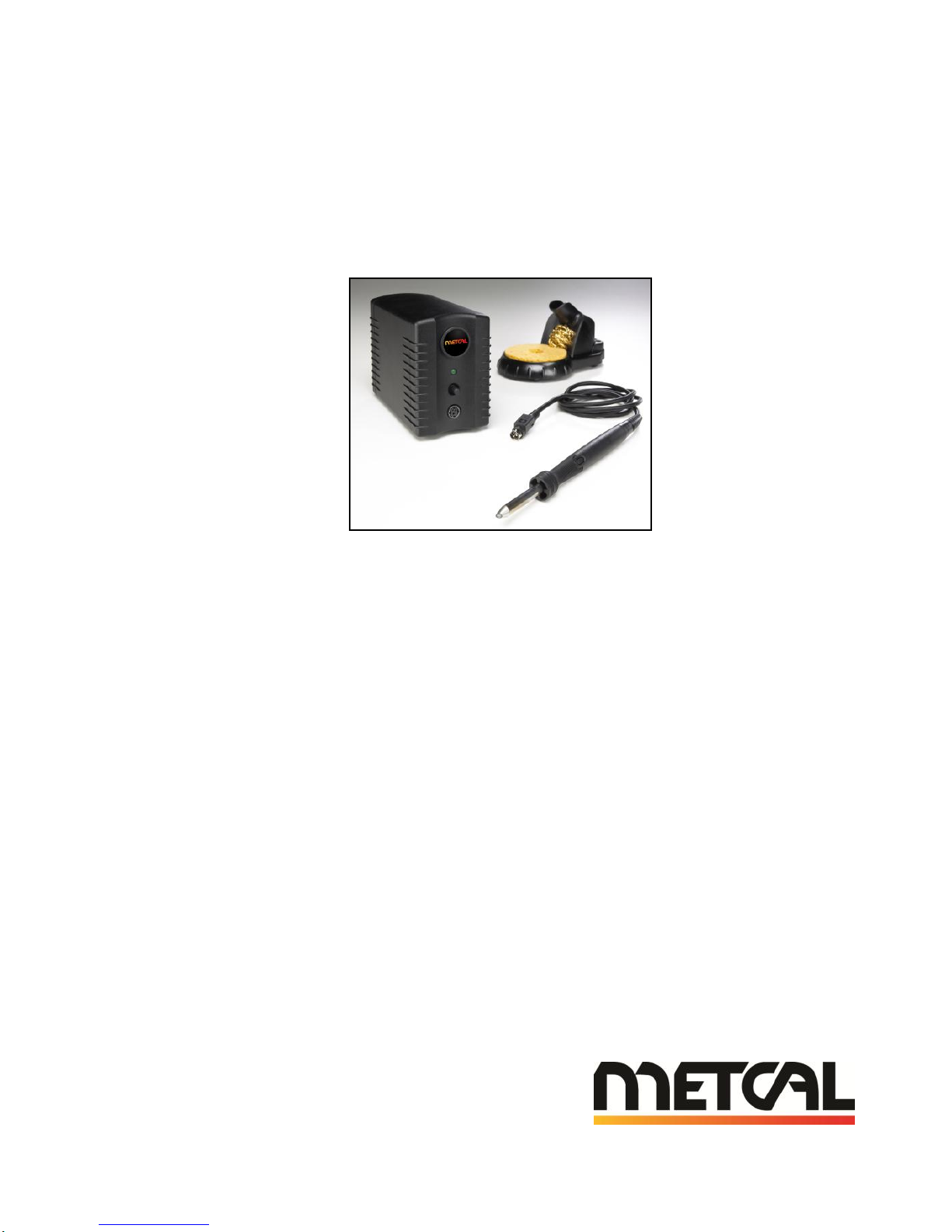

OK International warrants the PS-900 power supply and Handle cord assembly against any

defects in materials or workmanship for one (1) year from the date of purchase by the original

owner. This Warranty excludes normal maintenance and shall not apply to any opened,

misused, abused, altered or damaged items. If the product should become defective within the

warranty period, OK International will repair or replace it free of charge at its sole option. The

replacement item(s) will be shipped, freight prepaid, to the original purchaser. The warranty

period will start from the date of purchase. If the date of purchase cannot be substantiated the

date of manufacture will be used as the start of the warranty period.

SERVICE AFTER WARRANTY

OK International will repair or replace (at OK International's sole option) a PS-900 Power Supply

that fails in normal use within one year (1) year after the expiration of the one-year warranty at

the then current repair or exchange rate. To return a failed Power Supply for repair or

replacement, follow the steps outlined below. This repair/replace offer does not apply to any

previously opened, modified, repaired, altered, misused or damaged Power Supply.

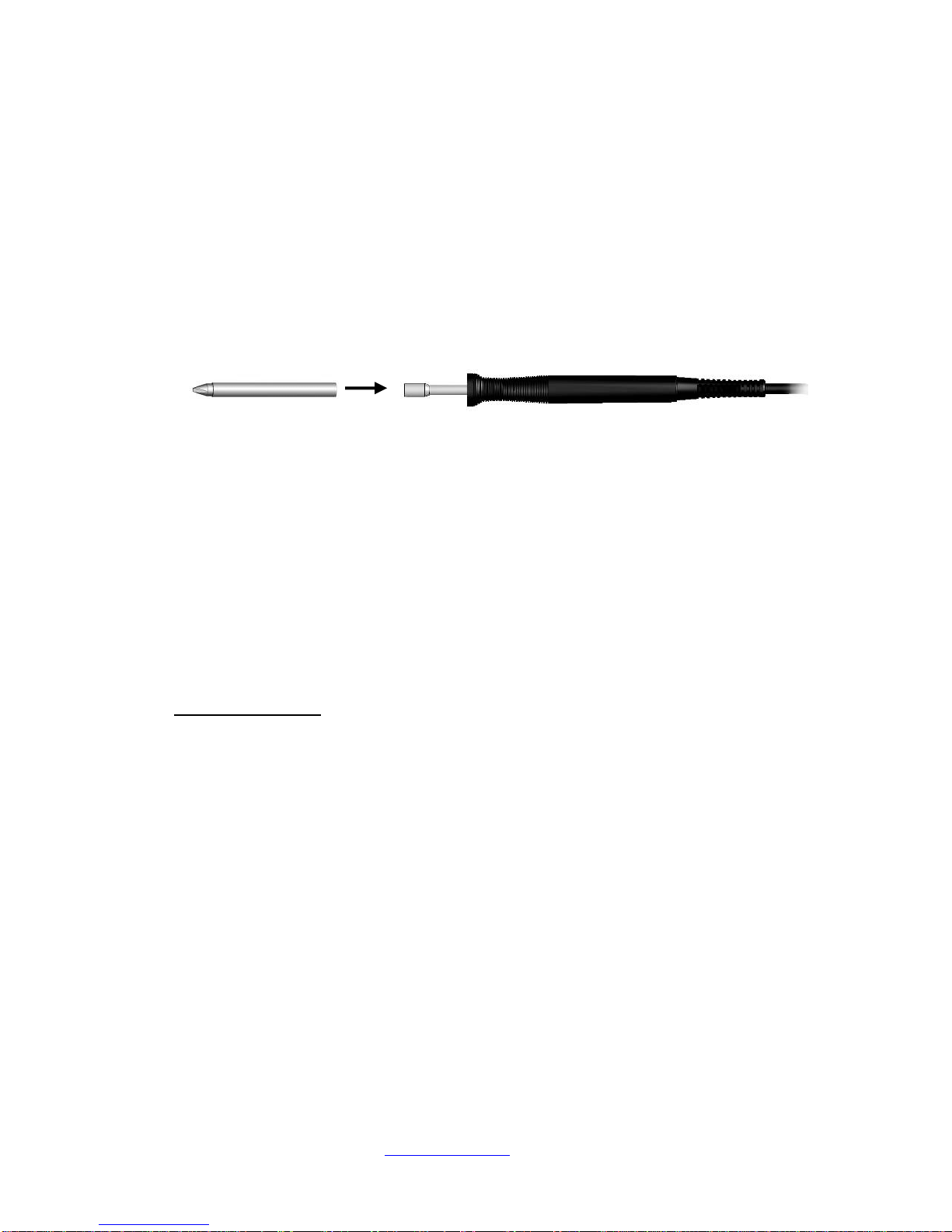

REPLACEABLE PS-CA3 HEATER COIL ASSEMBLY WARRANTY

OK International warrants the coil assembly against material and workmanship defects for a

period of 30 days.

REPLACEABLE TIP WARRANTY

OK International warrants that the heater-tip will operate according to specifications for the

lifetime of the tip plating. A heater tip that fails to heat during the lifetime of the plating will be

replaced at no charge. For replacement contact your local retail supplier. Because tip plating is

mainly dependent upon the user’s application and practices, tips are not warranted for plating

wear. Heater-tips are warranted against any defects in materials or workmanship. Misused,

abused, altered or damaged tips are not warranted. All heater-tips that fail to heat will be

repaired or replaced at OK International’s option. For returns follow the steps outlined below.

RETURN PROCEDURE

Please contact your local OK International Representative for return procedures and policies.