Michel's MIC210 User manual

Rev: 19/September/2017

MIC210 Electric Farm Conversion Instructions

Note: Apply the supplied Dielectric Lubricant to all wire connections when each wire is hooked up. The Dielectric

Lubricant will help to prevent corrosion.

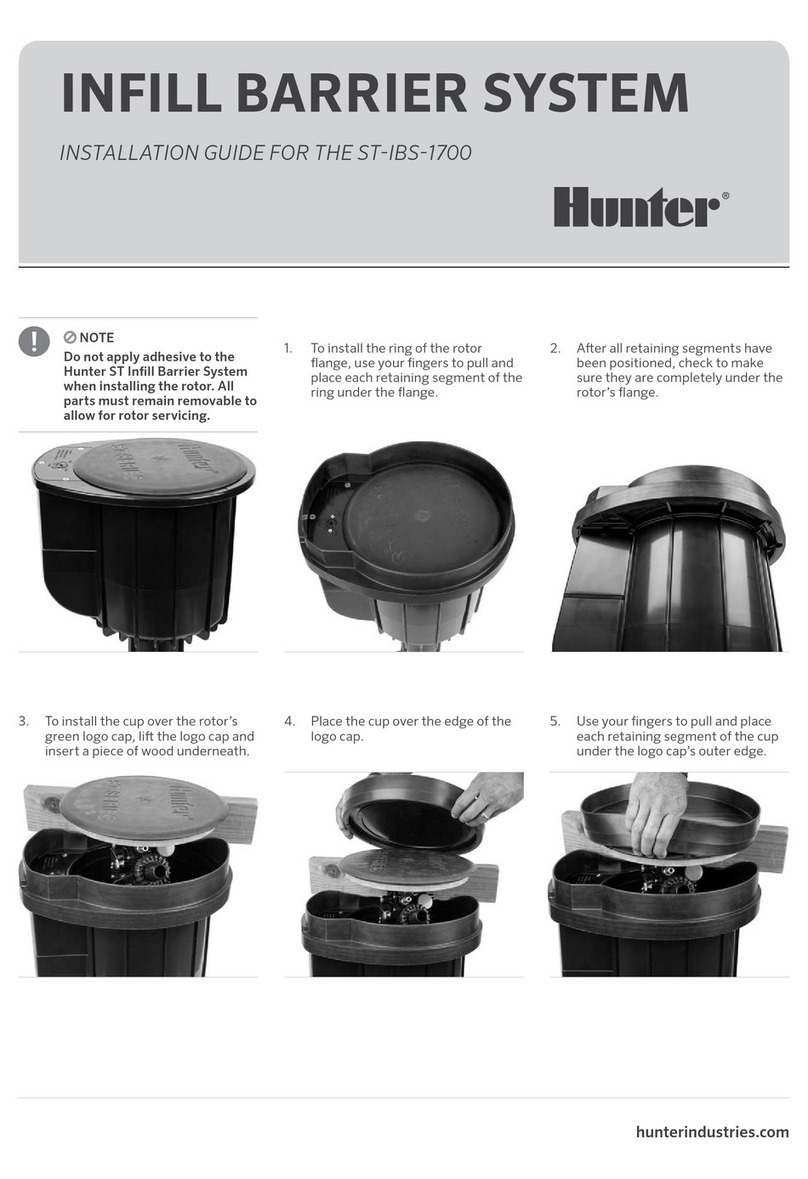

Step 1: Disassemble

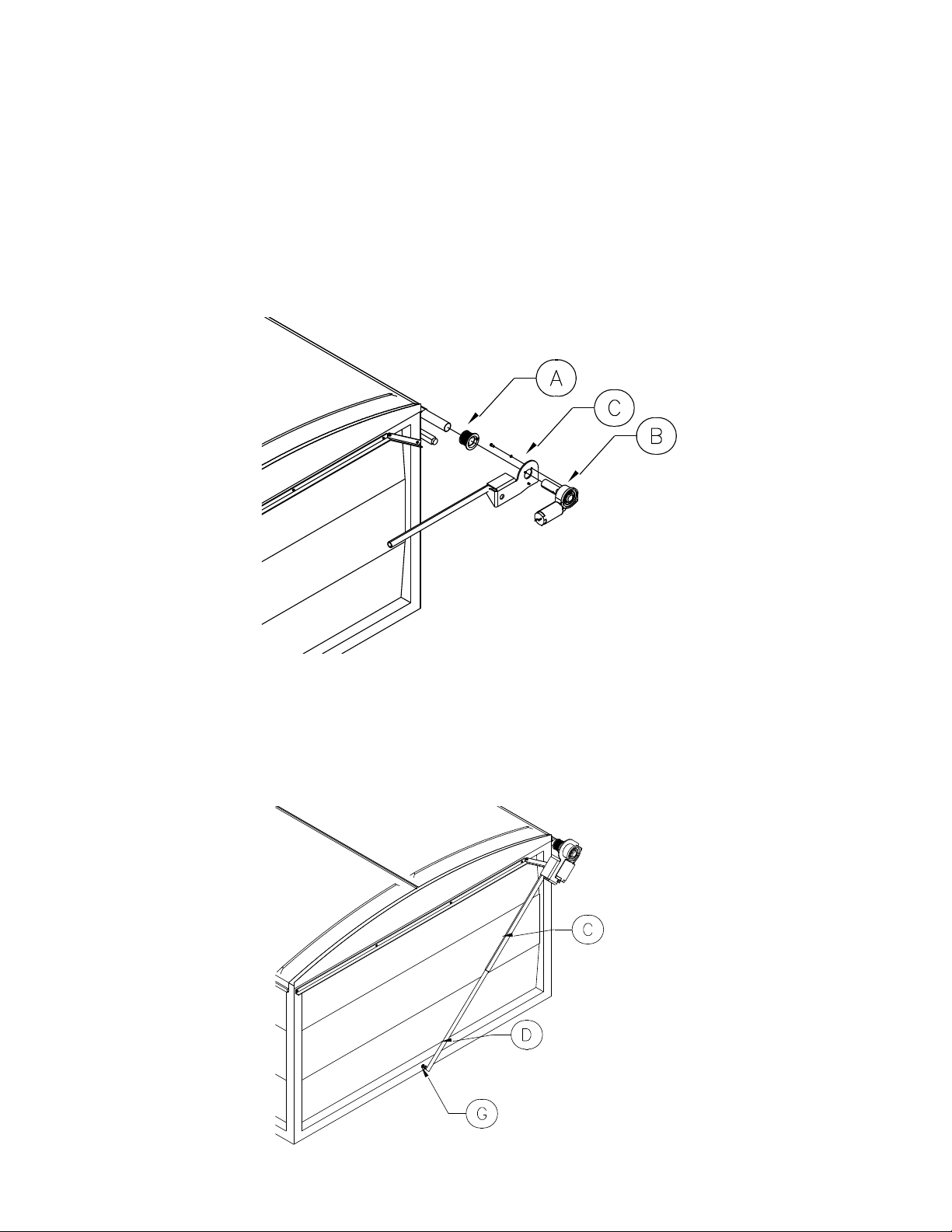

With the tarp all the way open, make a note of the number of

wraps of the tension cable on the front pulley (A) and measure

the distance from the pulley to the tarp. Now you can loosen the

pulley and remove it from the roll tube.

Step 2: Electric Pivot Arm Guide

Procedure: The electric pivot arm guide (X) is an aluminum

angle with one end bent down. Place on the front of the box

against the top rail of the box with the bent end on the driver’s

side. The bent end should be so it is just under the square tubing

of the holdbacks (see below). Secure to the box with 1/4"x1" lag

screws. You may need to bend it more and shorten the length if

necessary.

Step 3: Roll tube Preparation

If the roll tube does not stick at least 4” past the front of the box you will need to cut the roll tube back and weld

the supplied roll tube extension into the front of the roll tube. The minimum length of the extension piece can be

5-1/2” to the weld. After the roll tube extension is welded in, cut the front of the roll-tube so it sticks 4" past the

front of the box.

Step 4: Reinstall the front bevel pulley in the same location and wraps as were noted previously in Step 1.

Rev: 19/September/2017

Step 5: Electric Motor Installation

Note: The front beveled cable pulley (A) is stamped FRONT STANDARD and the rear beveled pulley is stamped

FRONT REVERSE.

Procedure: Mount the motor (B) to the electric bracket (C) with 5/16"x3/4" hex bolts and lock washers as shown.

Slide the motor assembly into the front of the roll-tube and swing the arm down in-between the box and the cab.

Drill a 5/16" hole through the roll-tube and the predrilled hole in the motor shaft, approximately 1" from the

bracket. Secure together with a 5/16"x2-1/4" hex bolt and jam nut. The 1/4"x3/8" set screws in the front and rear

beveled pulleys are to be tightened in Step 10.

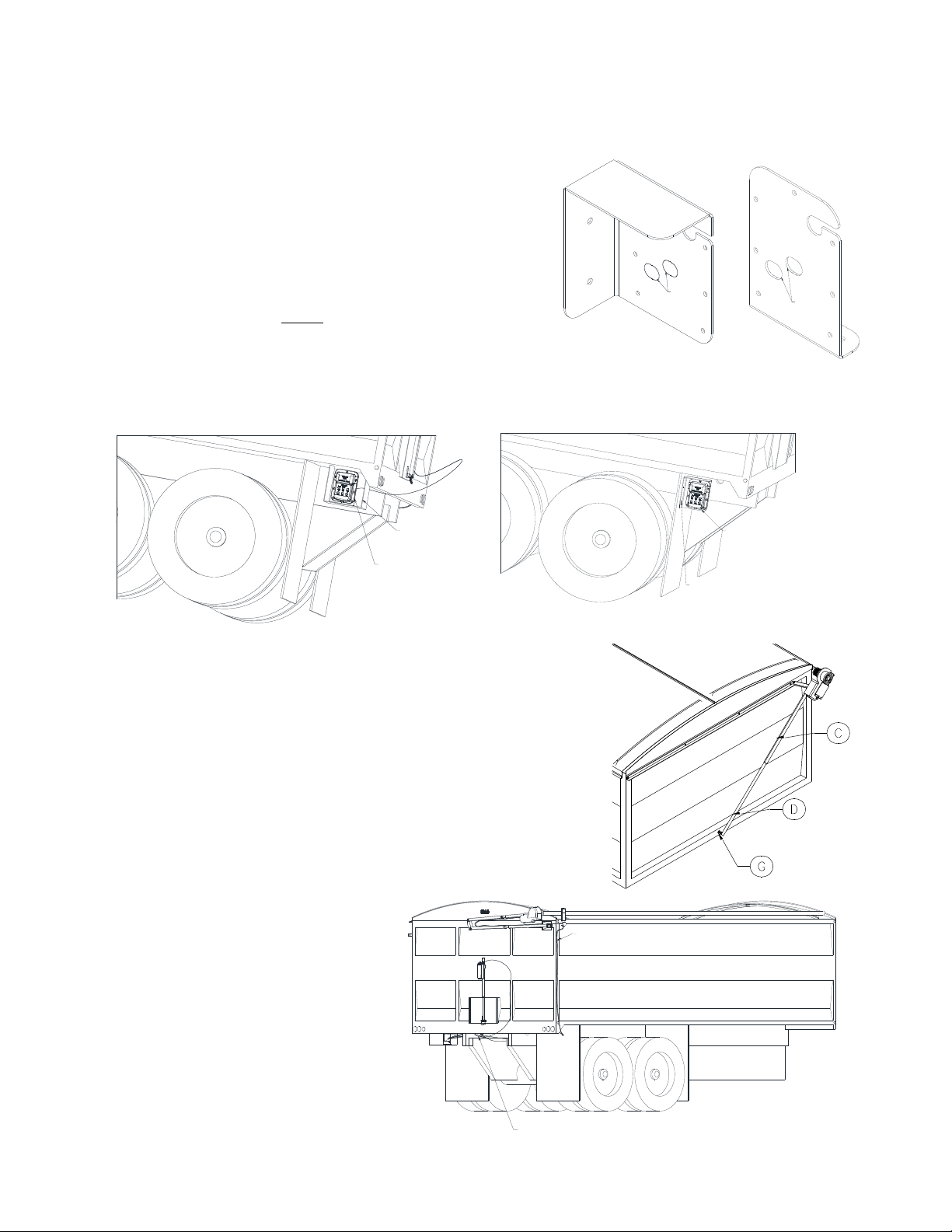

Step 6: Pivot Arm Installation

Procedure: To locate the pivot point on the front of the box, make a mark on the bottom sill of the box in the

middle of it. Note: Drill a 3/8" hole at pivot point (G) and slide the 1" round tubing (D) into the tubing on the

electric bracket (C). Secure the bottom tubing to the box with a 3/8"x4_1/2" hex bolt, 3/8" washers and nylon lock

nut.

Rev: 19/September/2017

Step 7.1: Rocker Switch Electrical Installation

Note:Apply the supplied Dielectric Lubricant to all wire connections when each wire is hooked up. The Dielectric

Lubricant will help to prevent corrosion.

Procedure: Mount the rocker switch in an obstruction free area inside the truck cab. Mount the solenoid on the

truck near the cab/batteries. Run the #6 double strand wire from the solenoid along the truck frame to the rear

box hinge point. Now run the wires along the box frame to the front box sill. Leave a slight amount of slack at

point (G) and continue running the wire along the pivot arm. Secure the wire to the top pivot arm (I) with the tie

straps provided. Attach the wire to the truck with the wire clips and 1/4"x1" self-tapping screws that are provided.

Connect the wires to the motor posts. The ends at the solenoid both get a black rubber boot and a #6-1/4" stud

crimped on.

Step 7.1: Rocker Switch Electrical Installation Cont.

Run the 14-3 wire from the solenoids to the rocker switch. At the switch each wire gets a 14G female end crimped

on and at the solenoid each wire gets a 14G female end except for the wire connected to the middle post of the

switch gets a 14G-1/4" ring terminal crimped on to connect to the positive post of the solenoid. Follow wiring

Schematic below, raise and lower the hoist to make sure that the wires are free from obstructions. Run #6 wire

from the solenoid to the battery posts. The wire with the red stripe will be the positive wire and will get bolted on

the positive post marked (+) along with the black 14Ga wire running from the switch. The black wire or negative

wire will be bolted onto the bottom negative post (-).Put the 50A circuit breaker in line with the positive wire.

Once everything is wired secure the motor cover to the motor with the 2 self-tapping screws provided.

ROCKER SWITCH

50AMP

CICUIT BREAKER

HEAVY DUTY REVERSE

DC CONTACTOR

BATTERY

NEGATIVE (-)

BATTERY

POSITIVE (+)

WIRE LEADS

TO MOTOR

Rev: 19/September/2017

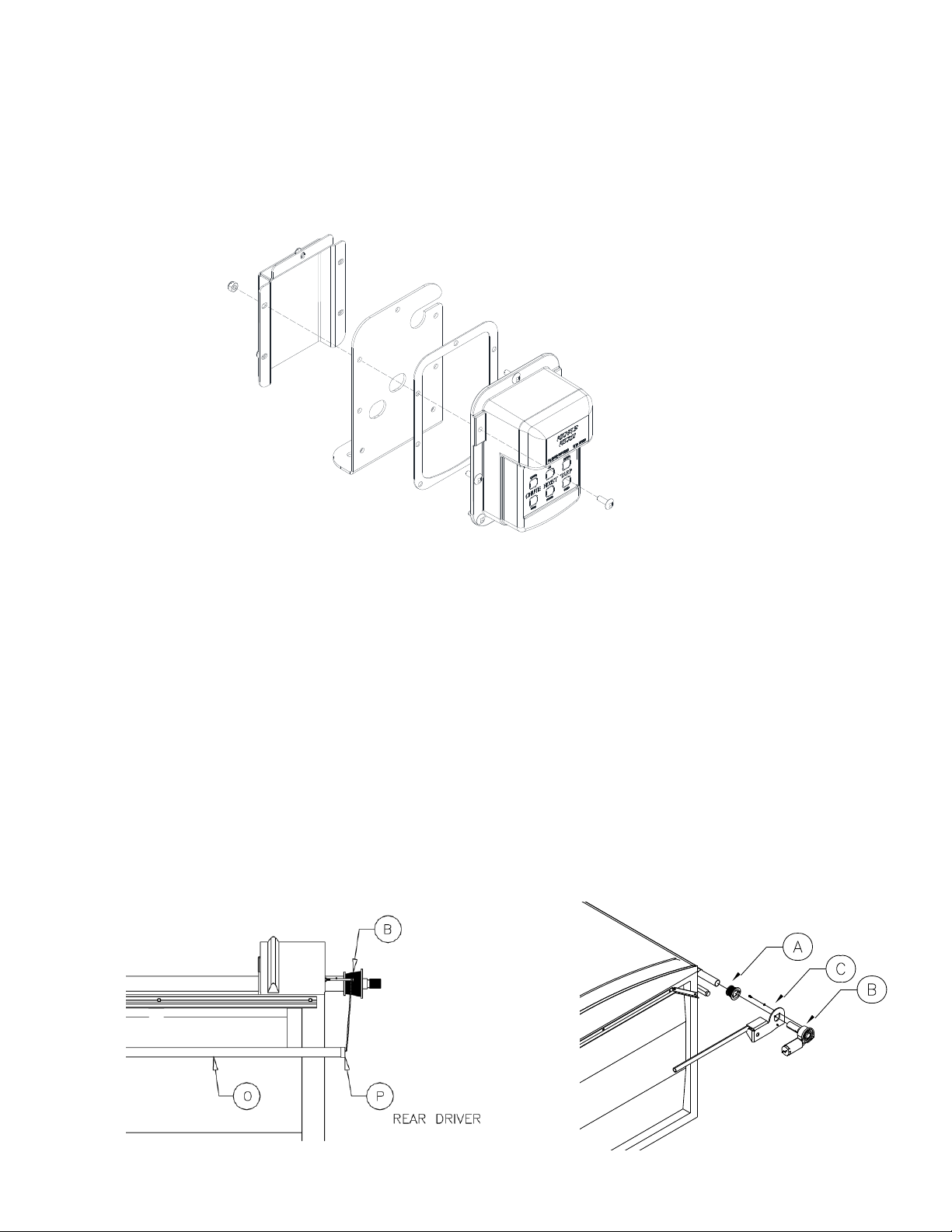

Step 7.1.1: MIC210 Control Box Installation

Depending on the grain box, two different mounting brackets may

be used. If the grain box already has a large ‘U’-shaped bracket

which houses air controls, use the basic plate. If not equipped with

this ‘U’ –shaped bracket then the shielded bracket which mounts to

the back side of the mud flap bracket should be used. The MIC210

Control Box mounting plate will be mounted to the box using the

3/8” bolts provided. Wire in the power wire and the electric tarp

motor wires (if applicable) before securing the MIC210 Control Box

to the mounting plate.

Step 7.1.2: Wiring the MIC210 System on a grain truck equipped

with an electric tarp

Run 6 AWG wire from the battery underneath the truck, along the frame to

the MIC210 control box. Make sure the inline circuit breaker is connected to

the positive wire near the battery, but do not connect to the battery until

all wire ends are connected correctly to refrain from shorting anything out.

Once the wires are installed and secured to the truck, thread the wires

through the appropriate hole (described below) of the mounting plate

coming in from behind the plate. Remove the punch outs with a chisel and

hammer. Place a grommet in each of the slots to protect the wires. Run the

#6 double strand wire from the MIC210 box

along the truck frame to the rear box hinge

point. Now run the wires along the box

frame to the front box sill. Leave a slight

amount of slack at point (G) and continue

running the wire along the pivot arm.

Secure the wire to the top pivot arm (I) with

the tie straps provided. Attach the wire to

the truck with the wire clips and 1/4"x1"

self-tapping screws that are provided.

MIC210 MOUNTED

TO BRACKET

SHIELDED MUD FLAP

BRACKET MOUNT

BOLTED TO STEEL

MUD FLAP MOUNT

PUNCH

OUTS

Shielded Mud Flap Bracket Mount

PUNCH

OUTS

Basic Plate

BASIC MOUNTING

PLATE

U-SHAPED

BRACKET

WIRES THROUGH HOLE

IN THE FRAME

TARP WIRE

Rev: 19/September/2017

Connect the wires to the motor posts. The ends at the MIC210 box and the motor all get a #6-1/4" stud crimped

on. These motor wires thread through the middle hole on the mounting plate. The incoming power wires thread

through the bottom hole of the bracket. Make sure the grommets have been installed to protect the wire. The

third hole at the top of the bracket is for the hoist and the Power Pro leads. Slide them into the top hole using the

slot. The third grommet will need to be split using a pair of side cutters or a knife. Wrap the split grommet around

the actuator and hoist leads. Then insert it into the top hole. Next, connect the power wires to the solenoid. The

positive wire goes on the positive post (top left) of the solenoid. The negative wire goes on the negative post (top

right) of the solenoid. Then, connect the tarp motor wires to the solenoid. These wires connect to the remaining

bottom posts on the solenoid. It does not matter which wire goes where on these two posts. If they end up being

backwards to the remote there is a very simple setting in the remote which can reverse them without having to

physically switch the wires. Please see the R200 Remote instruction manual, Section 4.2.2. There is a specific way

in which the 6 AWG wires must be positioned in order to fit inside the MIC210 Control Box. Please refer to the

Diagram on the next page. Once all the wires are connected to the MIC210 box connect the wires to the battery to

ensure everything works before carrying on to securing the box to the mounting plate.

POWER

NEGATIVE

TARP WIRE

RUN THIS WIRE

ON THE OUTSIDE

OF THE BUMP

POWER

POSITIVE

TARP WIRE

RUN THESE THREE

WIRES ON THE

INSIDE OF THE BUMP

CIRCUIT BREAKER

TO MOTOR

FROM BAT (-)

TO MOTOR

FROM BAT (+)

Rev: 19/September/2017

Securing MIC210 Control box to Mounting Plate

Start by mounting the control box and gasket to the mounting plate by using the bottom two holes in the control

box, this will aid in holding everything in place before you install the back cover. Next make sure your wires are still

remaining in the correct positions according to the diagram to refrain from pinching anything, install the back

protective cover using the remaining five holes in the control box.

Step 8: Beveled Cable Pulley Installation & Tension Control Adjustment

Procedure: Roll the tarp to the open position.

1. Installing cable onto rear beveled pulley:

Pull the cable from the rear holdback system (O) towards the rear beveled pulley stamped FRONT REVERSE (B).

Insert cable end into pulley slot and rotate beveled pulley 1-3/4 turns for an 8-1/2ft box or 2-1/4 turns for an 8ft

box. Rotate the pulley from the underside of it on the large diameter. Properly position the beveled pulley on the

roll-tube so that the nylon cable- guide (P) on the holdback lines up with the small diameter on the pulley. Tighten

the 1/4"x3/8" set screws (B) to hold the pulley in place.

2. Installing cable onto front beveled pulley:

Pull the cable from the front holdback system towards the front beveled pulley stamped FRONT STANDARD (A).

Repeat the rear beveled pulley procedure. Roll the tarp open and closed several times checking each time to make

sure that the cable follows in the pulley grooves and the tarp rolls evenly. If the cable does not follow in the

grooves, move the beveled pulley in or out until the correct position is achieved. If the tarp does not roll evenly,

roll the tarp to the open position; loosen the 1/4"x3/8" set screws in the front and rear pulleys and increase the

wrap. This will increase the tension. Do not allow the pulley to have less than one complete wrap of cable when

the tarp is in the open position.

Rev: 19/September/2017

Optional Manual Override

Step 1: Remove the motor cover and disconnect the motor from the power supply.

Step 2: Remove the plastic cap covering the manual input shaft. Do not use the manual override when the motor

is running or the motor is connected to the power supply.

Step 3: Using a 1/2in socket and a speed ratchet or impact driver, simply slide onto the manual input shaft and

drive the gearbox as needed. Keep in mind that 90 revolutions of input will result in one revolution of output.

Step 4: Remove the driver and re-install the plastic cap.

Warranty

Michel's Industries warrants their products for a period of one year from date of purchase. Any parts returned to

Michel's Industries LTD. will be shipped prepaid by the customer and will be returned F.O.B. St. Gregor, Sk. Canada.

We will not assume responsibility for shipping, labor or travel expenses. Please Note: We reserve the right to

make improvements; therefore specifications are subject to change without notice.

Note: If wiring is hooked up incorrectly it will void your warranty.

The enclosed device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (i.) this device may not cause

harmful interference and (ii.) this device must accept any interference received, including interference that may cause undesired operation.

Contains FCC ID: MCQ-XB900HP

Contains IC: 1846A-XB900HP

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

***For Remote Operation and Programming functions refer to the R200 Remote

Instruction Manual Section 8.0.0***

Rev: 19/September/2017

Michel's Industries LTD.

P.O. Box 119

St. Gregor, SK S0K 3X0

CANADA

TEL: (306) 366-2184 FAX: (306) 366-2145

www.michels.ca

Other manuals for MIC210

1

Table of contents

Other Michel's Farm Equipment manuals

Popular Farm Equipment manuals by other brands

aivituvin

aivituvin AIR 18 instruction manual

AGCO

AGCO Cumberland Flex-Flo 220 installation manual

Sly France

Sly France BOSS Series operating instructions

FARMTECH

FARMTECH T-DCBM-4 user manual

Nutriculture

Nutriculture Amazon Aeroponic System Assembly and operating instruction

Toro

Toro 41614 installation instructions

GREAT PLAINS

GREAT PLAINS Ultra-Till I 3030 Series Operator's manual

pronovost

pronovost SilaTube P-6500 Operator and parts manual

Killbros

Killbros 575 Operator's Manual/Parts Catalog

BOXER

BOXER SB user manual

Monosem

Monosem NG Plus 2 Operator's manual

Raven

Raven AutoBoom Case IH Patriot 250 installation manual