1

INDEX

SECTION 1 GENERAL INFORMATION ____________________________________________________2

1.1 WARRANTY ___________________________________________________________________2

SECTION 2 GUIDE TO THE SIGNS AND SYMBOLS USED____________________________________3

2.1 SIGNS AND SYMBOLS __________________________________________________________3

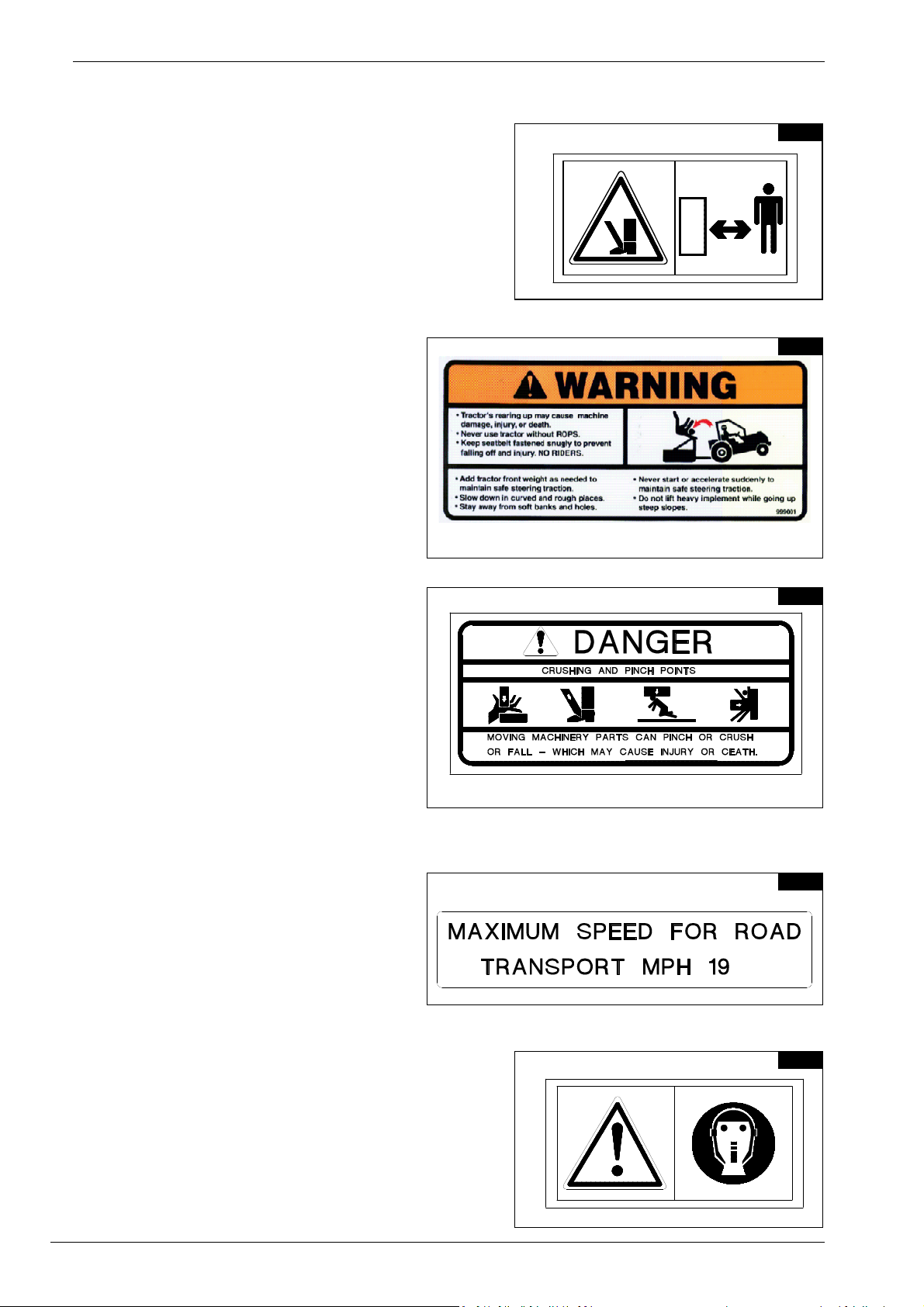

2.2 WARNING SIGNS _______________________________________________________________3

2.3 WARNINGS IN THE MANUAL _____________________________________________________5

2.4 INDICATION SIGNS _____________________________________________________________5

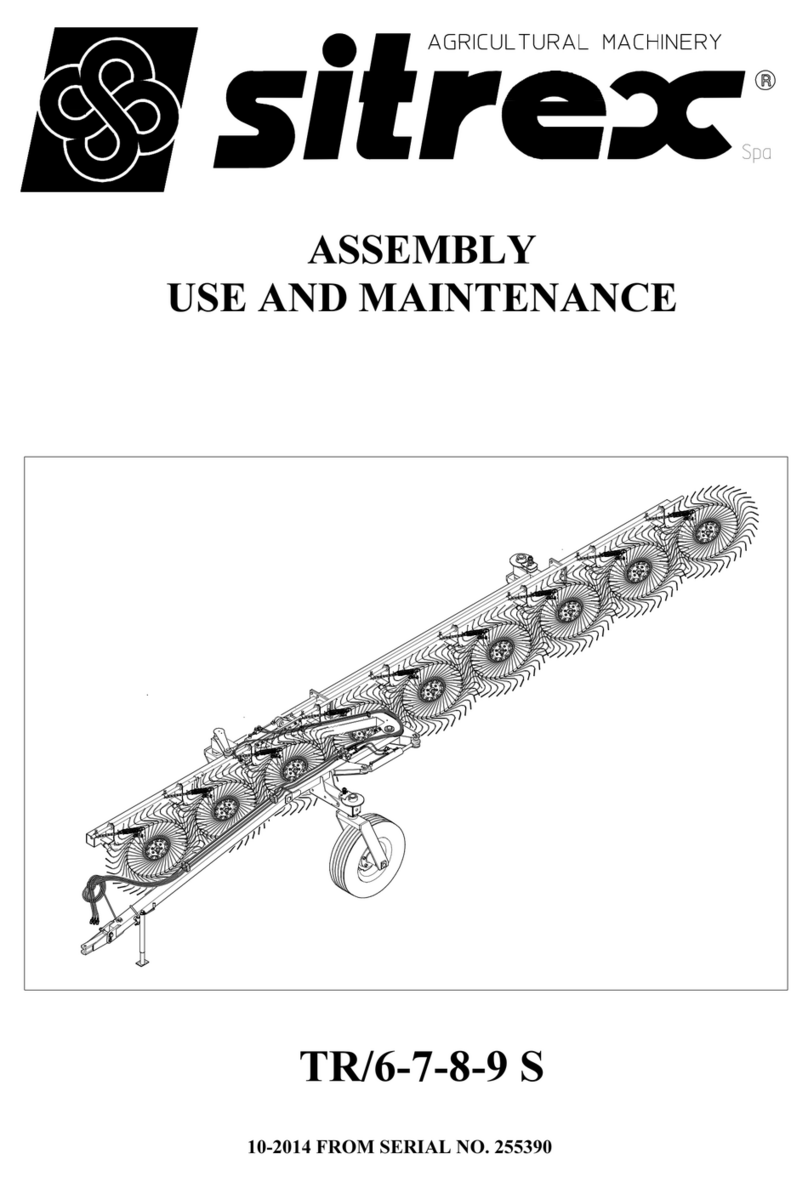

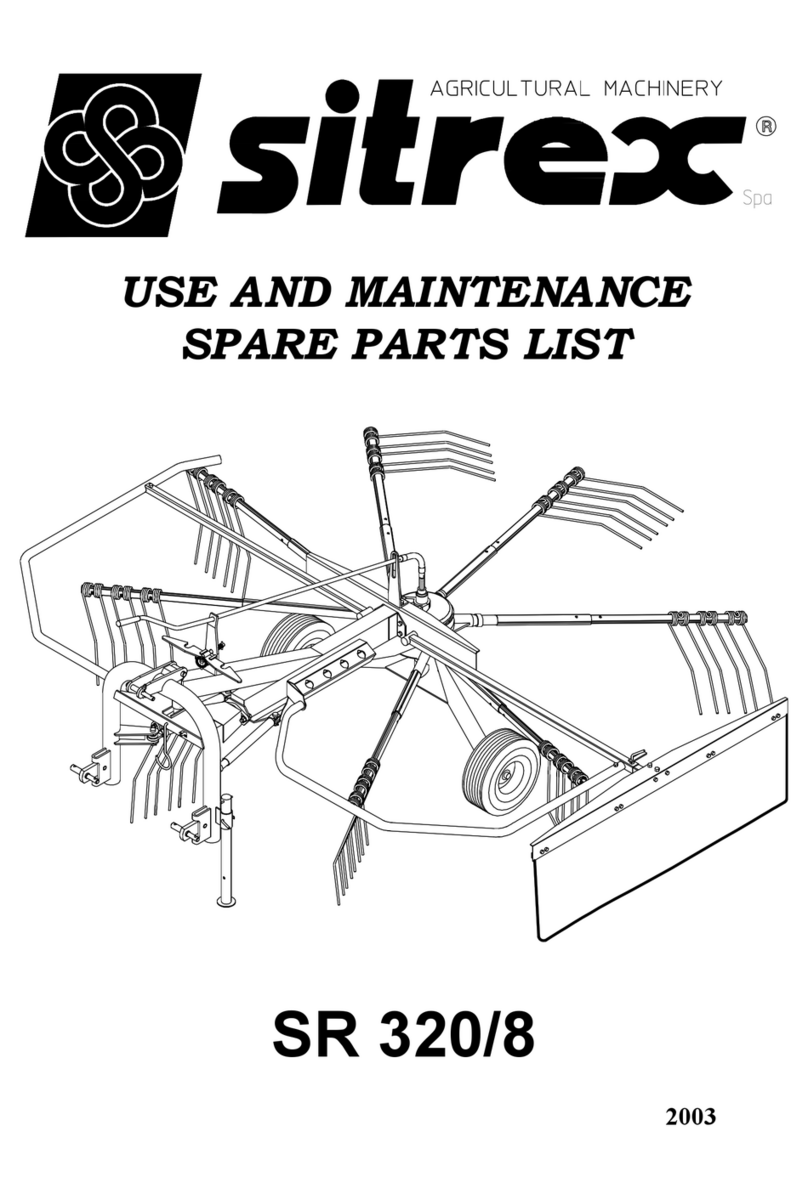

SECTION 3 TECHNICAL SPECIFICATIONS ________________________________________________6

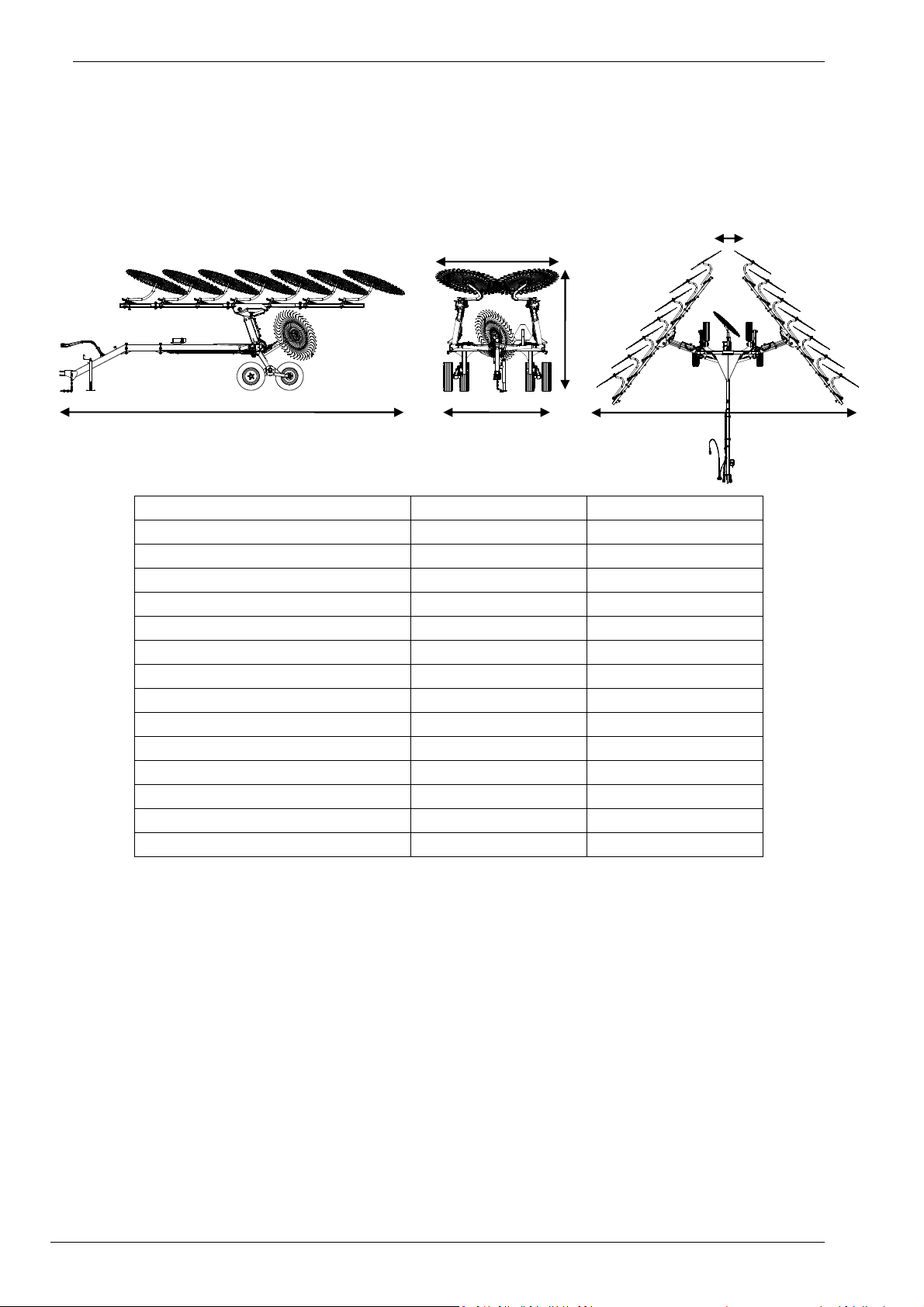

3.1 MACHINE TECHNICAL SPECIFICATIONS ___________________________________________6

3.2 CHARACTERISTICS OF HYDRAULIC/ELECTRIC COMPONENTS________________________6

3.3 MACHINE IDENTIFICATION ______________________________________________________7

3.4 MACHINE IDENTIFICATION DATA _________________________________________________8

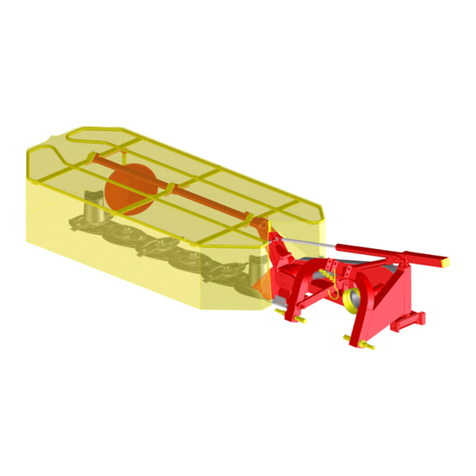

SECTION 4 ASSEMBLY ________________________________________________________________9

4.1 DELIVERY AND UNPACKING._____________________________________________________9

4.2 ASSEMBLY INSTRUCTIONS _____________________________________________________10

4.3 METRIC–INCHES CONVERSION TABLE ___________________________________________11

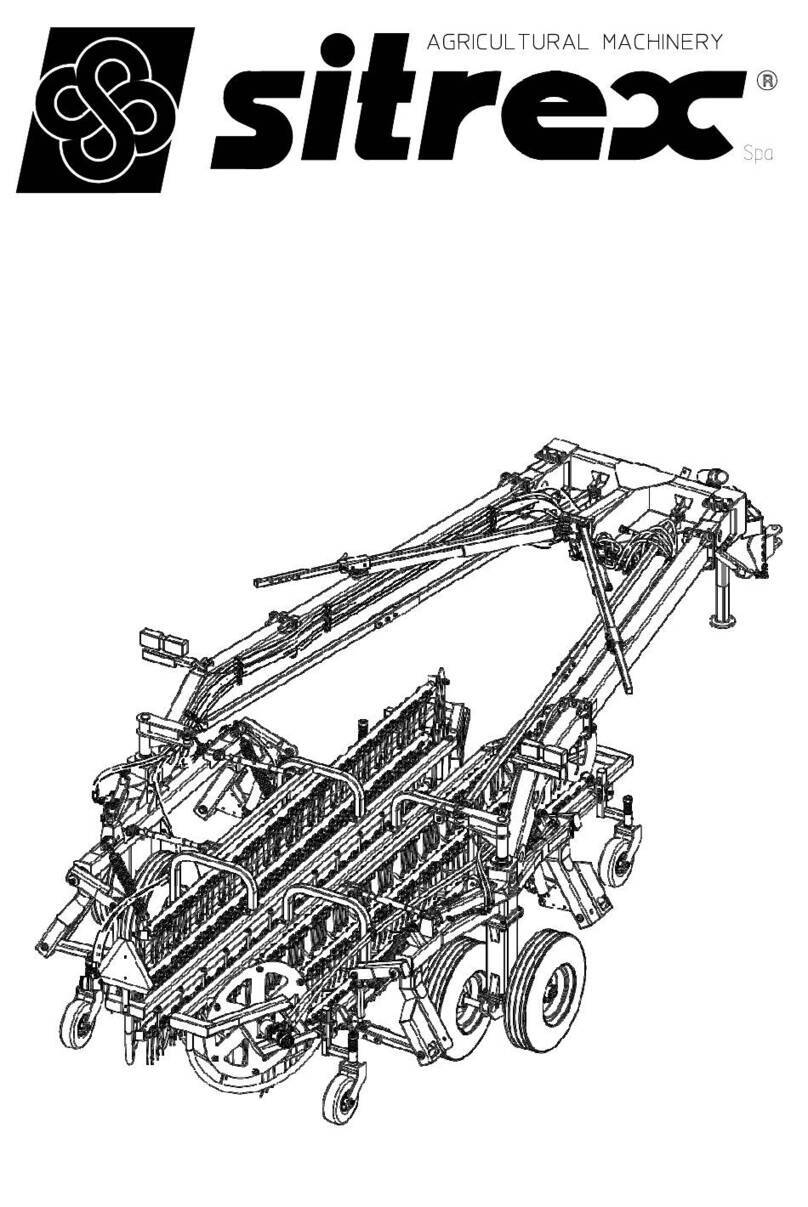

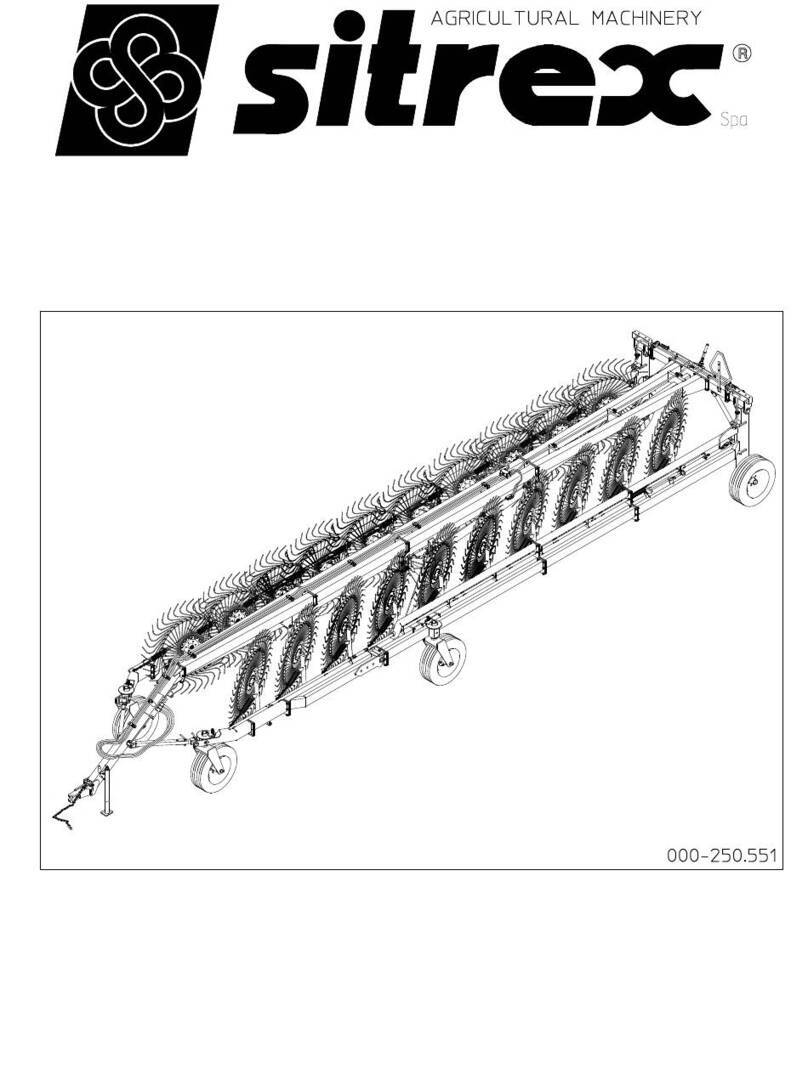

4.4 MACHINE ASSEMBLY __________________________________________________________12

4.5 HYDRAULIC SYSTEM ASSEMBLY ________________________________________________21

4.6 ELECTRICAL SYSTEM ASSEMBLY _______________________________________________28

4.7 CENTER RAKE WHEEL KIT (OPTIONAL)___________________________________________29

4.8 ASSEMBLY OF CONVERSION KIT FROM QRX12 TO QRX14 __________________________33

4.9 GREASING POINTS ____________________________________________________________35

SECTION 5 ADJUSTMENT, PREPARATION AND USE ______________________________________36

5.1 HITCHING THE MACHINE TO THE TRACTOR_______________________________________36

5.2 UNHITCHING THE MACHINE FROM THE TRACTOR _________________________________37

5.3 ELECTRIC SELECTOR _________________________________________________________38

5.4 ROAD TRANSPORT ____________________________________________________________41

5.5 COMPLIANCE WITH THE HIGHWAY CODE_________________________________________43

5.6 WORKING POSITION ___________________________________________________________43

5.7 ADJUSTING THE PRESSURE OF THE RAKE WHEELS ON THE GROUND _______________44

5.8 WORKING POSITION ADJUSTMENTS. ____________________________________________45

5.9 WORKING ON ONE SIDE ONLY __________________________________________________46

5.10 Locking the rake wheel arms in the raised position_____________________________________48

SECTION 6 GENERAL INSTRUCTIONS FOR MAINTENANCE ________________________________49

6.1 REPAIR WORK ________________________________________________________________49

6.2 STORAGE FOR LONG PERIODS _________________________________________________49

6.3 MAINTENANCE INSTRUCTIONDS ________________________________________________50

6.4 TIRES _______________________________________________________________________50

6.5 HYDRAULIC CIRCUIT __________________________________________________________50

6.6 SCRAPPING THE MACHINE _____________________________________________________51