CONTENTS

1. GENERAL INFORMATION................................................................................... 1

2

7

16

22

36

41

3. DIAGNOSTICS.........................................................................................................

5. REPLACING COMPONENTS............................................................................

6. CIRCUIT DIAGRAMS AND BOARDS............................................................

7 COMMISSIONING THE APPLIANCE..............................................................

4. SAFE WORKING WHEN TESTING COMPONENTS................................

2. HAZARDS AND SAFETY PRECAUTIONS...................................................

1.1 Purpose of this chapter........................................................................................................................

1.2 Equipment details Generic................................................................................................................

1.3 Important Information.........................................................................................................................

1.4 Structure of technical documentation.........................................................................................

1.5 About this Service Manual.................................................................................................................

2.1 Hazards and safety precautions during installing...................................................................

2.2 Hazards and safety precautions during servicing and repair...........................................

2.3 Hazards and safety precautions when taking the appliance out of service..............

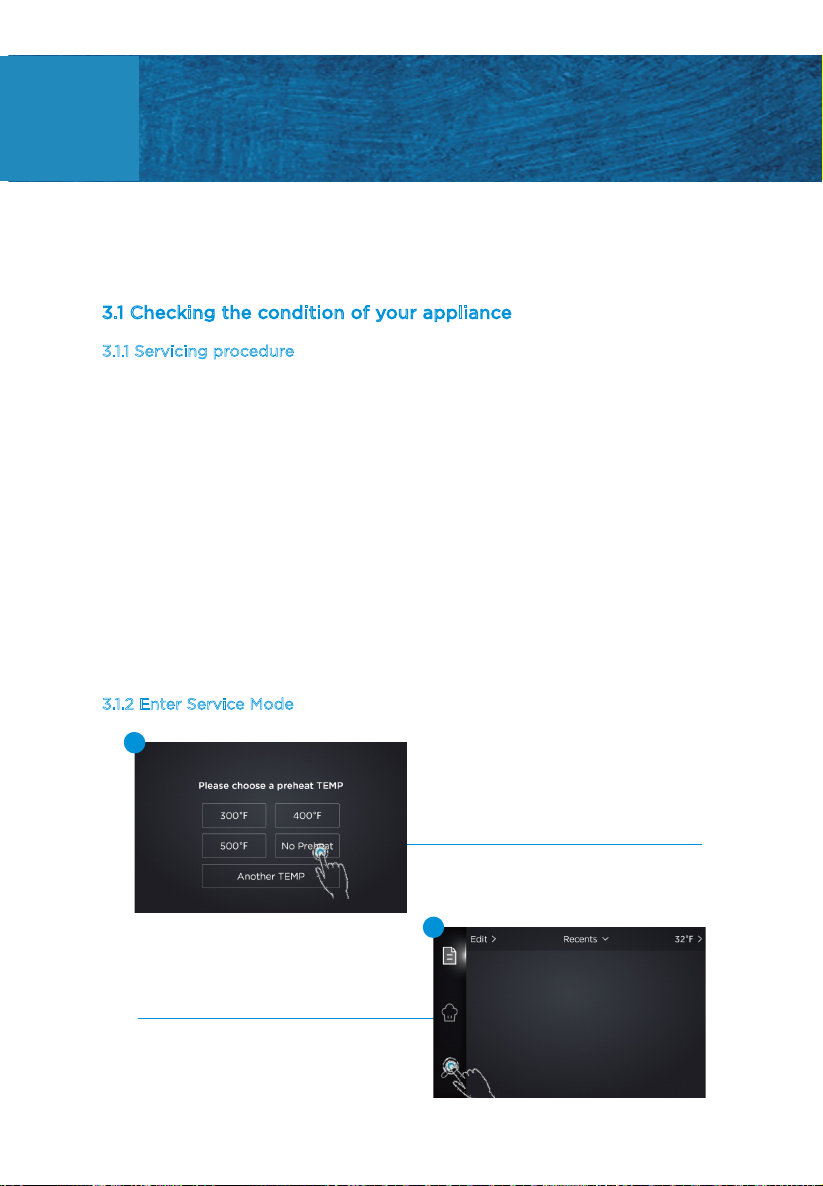

3.1 Checking the condition of your appliance..................................................................................

3.2 Fault finding............................................................................................................................................

4.1 Electrically live components.............................................................................................................

4.2 Moving heavy loads.............................................................................................................................

4.3 Sharp-edged sheet-metal parts.....................................................................................................

4.4 Hot surfaces............................................................................................................................................

4.5 Live components..................................................................................................................................

4.6 Microwave emissions..........................................................................................................................

4.7 Fire / smoke in the appliance..........................................................................................................

4.8 Requirements.........................................................................................................................................

4.9 Testing selected components (casing mounted)...................................................................

4.10 The key components (casing removed)...................................................................................

4.11 Mains voltage components (casing removed)........................................................................

5.1 Safe working when replacing appliance parts..........................................................................

5.2 Parts and their function.....................................................................................................................

5.3 Overview..................................................................................................................................................

5.4 Removing / fitting the casing.........................................................................................................

6.1 SRB / QTS circuit boards...................................................................................................................

6.2 TFT Driver Board..................................................................................................................................

6.3 Circuit diagrams....................................................................................................................................

7.1 Recommission Test: Recommissioning the appliance after service/repair...................

1

1

5

7

16

28

36

40

41

38

25

24

22

20

19

18

18

18

17

17

17

16

16

10

3

2

1

1

1