Contents

Notice......................................................................................................................................................i

Notes about structure and electric circuit design.....................................................................................ii

Contents................................................................................................................................................ iii

1 Specifications ..................................................................................................................................... 1

1-1 Technical specifications .............................................................................................................. 1

1-2 Electrical interface/Pin assignment ............................................................................................. 2

1-3 Default settings for various types of barcode .............................................................................. 3

1-4 Decode zone............................................................................................................................... 4

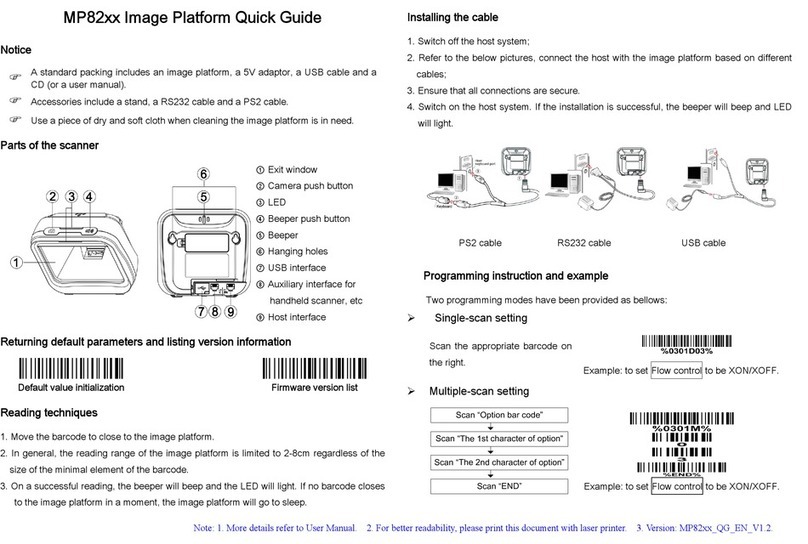

2 Installation guide ................................................................................................................................ 6

2-1 Important notes of installation ..................................................................................................... 6

2-2 Mounting ..................................................................................................................................... 6

2-3 Appearance of the scanner ......................................................................................................... 7

2-4 Scan angle .................................................................................................................................. 8

3 Parameter menus............................................................................................................................... 9

3-1 Example: Configure scanner by scanning configuration barcodes.............................................. 9

3-2 RS-232 interface ....................................................................................................................... 11

3-3 USB interface............................................................................................................................ 14

3-4 Scan mode & some global settings........................................................................................... 17

3-5 Indication................................................................................................................................... 21

3-6 UPC-A....................................................................................................................................... 22

3-7 UPC-E....................................................................................................................................... 24

3-8 UPC-E1..................................................................................................................................... 26

3-9 EAN-13 (ISBN/ISSN) ................................................................................................................ 28

3-10 EAN-8 ..................................................................................................................................... 30

3-11 Code 39 (Code 32, Trioptic Code 39) ..................................................................................... 32

3-12 Interleaved 2 of 5 .................................................................................................................... 35

3-13 Industrial 2 of 5........................................................................................................................ 37

3-14 Matrix 2 of 5 ............................................................................................................................ 38

3-15 Codabar .................................................................................................................................. 40

3-16 Code 128 ................................................................................................................................ 42

3-17 UCC/EAN 128......................................................................................................................... 44

3-18 ISBT 128 ................................................................................................................................. 46

3-19 Code 93 .................................................................................................................................. 48

3-20 Code 11 .................................................................................................................................. 50

3-21 MSI/Plessey ............................................................................................................................ 52

3-22 UK/Plessey ............................................................................................................................. 54

3-23 China Post .............................................................................................................................. 56

3-24 China Finance......................................................................................................................... 57