II

Index

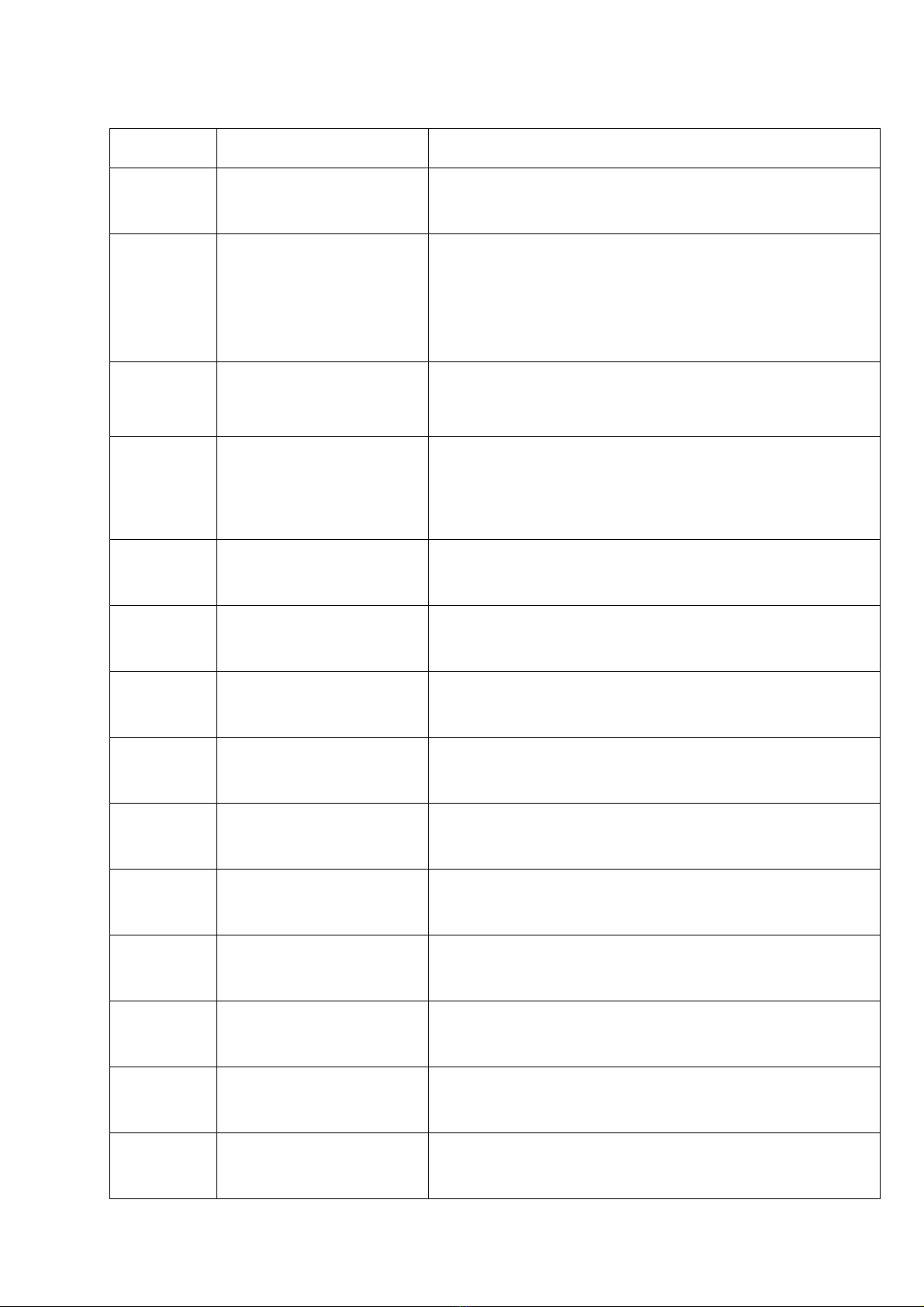

FORWARD .......................................................................................................................................................................................................... I

MARKS AND ARRANGEMENTS USED IN THIS MANUAL ............................................................................................. I

FOR SAFE OPERATION .......................................................................................................................................................................... I I

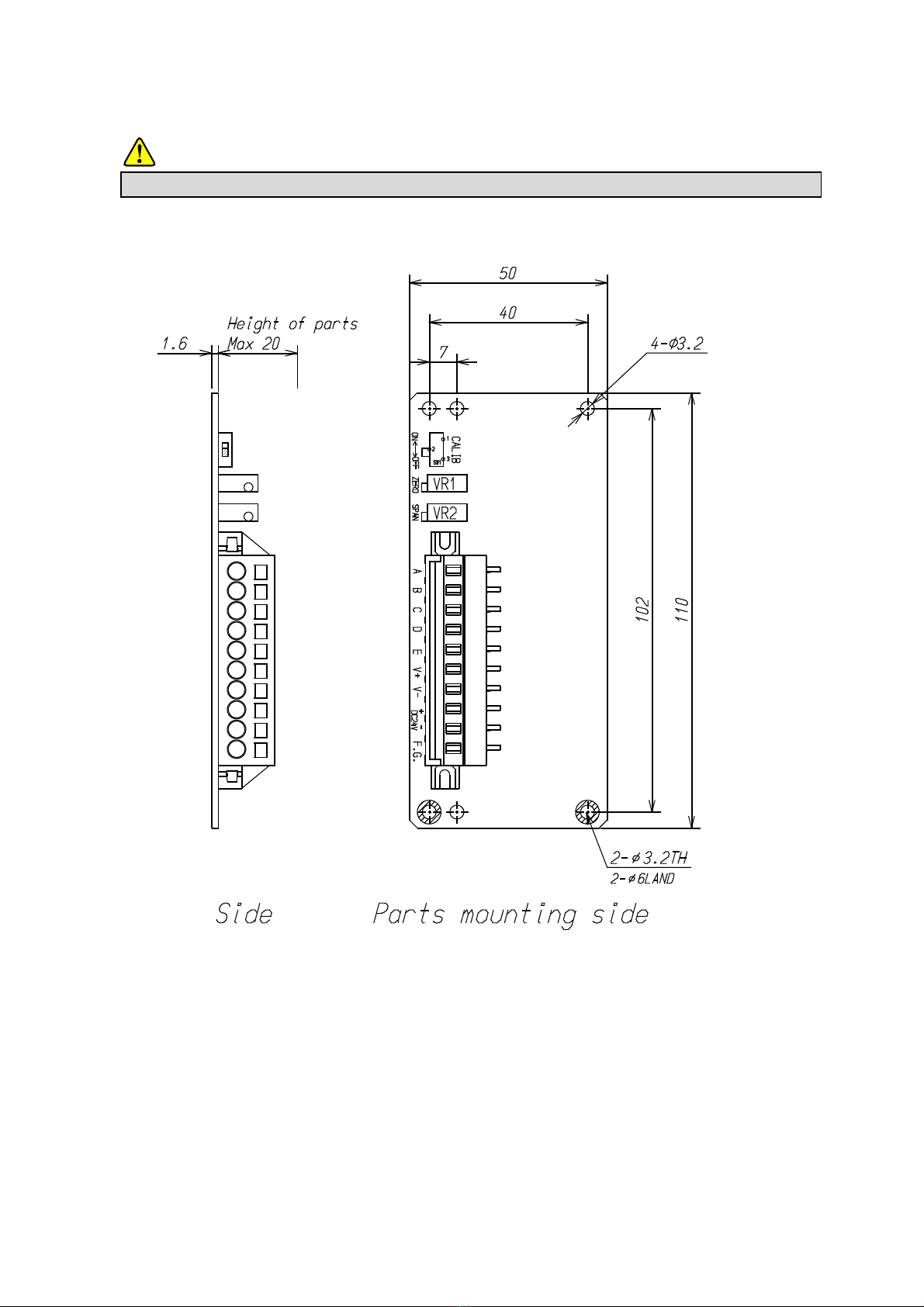

1. INSTRATION PLACE .................................................................................................................................................................................... II

2. POWER SUPPLY ........................................................................................................................................................................................ IV

3. APPLICATION NOTE ................................................................................................................................................................................ IV

HISTORY OF REVISION ......................................................................................................................................................................... V

1. EACH FUNCTION AND NAME............................................................................................................................................... 1

2. CONNECTING METHOD ............................................................................................................................................................ 3

2-1. LAYOUT OF THE TERMINAL BOARDS ........................................................................................................................................ 3

2-2. NOTE ON CONNECTION.................................................................................................................................................................... 3

2-3. CONNECTION ........................................................................................................................................................................................ 4

3. CALIBRATION .................................................................................................................................................................................... 8

3-1. CALIBRATION METHOD .................................................................................................................................................................... 8

3-2. CLIBRATION PROCEDURES ............................................................................................................................................................. 9

3-3. ZERO ADJUSTMENT BY MOUNTING RESISTANCE ............................................................................................................ 11

4. TROUBLE SHOOTING .............................................................................................................................................................. 14

5. SPECIFICATIONS ......................................................................................................................................................................... 20

5-1. SPECIFICATIONS .............................................................................................................................................................................. 20

5-2. GENERAL SPECIFICATIONS ......................................................................................................................................................... 20

5-3. STANDARD SPECIFICATION AT THE TIME OF SHIPMENT ............................................................................................. 20

5-4. ACCESSORIES .................................................................................................................................................................................. 20

6. WARRANTY ..................................................................................................................................................................................... 21

6-1. WARRANTY ....................................................................................................................................................................................... 21

6-2. REPAIR ................................................................................................................................................................................................. 21