1

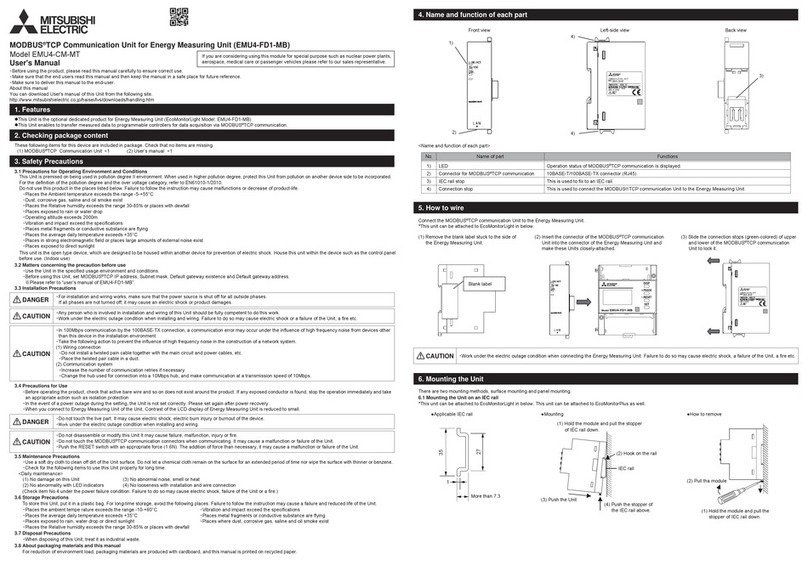

1. Overview

This manual explains the CC-Link IE controller network communication unit

(hereinafter referred to as CC-Link IE communication unit).

The CC-Link IE communication unit allows the GOT1000 series to function as a

normal station on the CC-Link IE controller network.

Refer to GT15 User's Manual for GOT to which this unit can be installed.

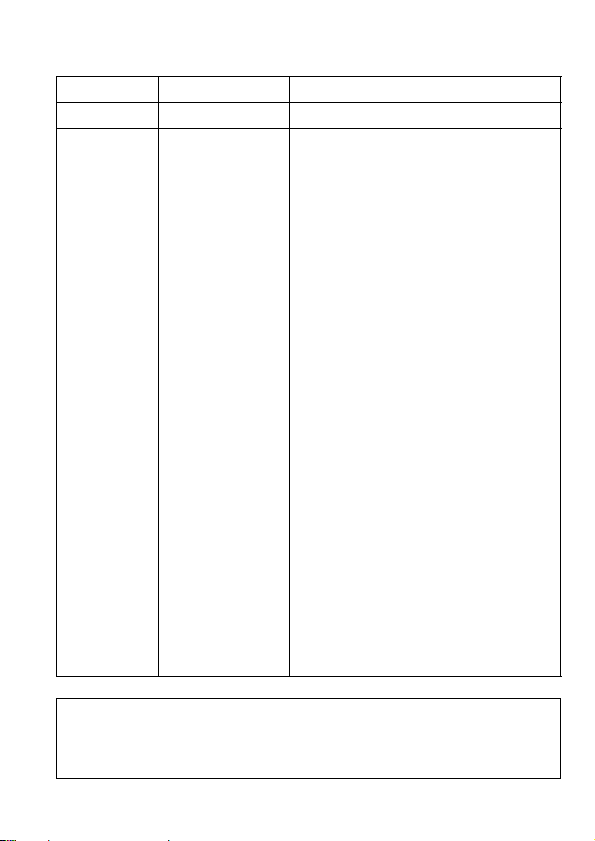

2. Specifications

The performance specifications of the CC-Link IE communication unit are

indicated below.

The general specifications of the CC-Link IE communication unit are the same as

those of the GOT.

For the general specifications of the GOT, refer to GT15 User's Manual.

When using the CC-Link IE controller network connection, make the

communication setting to perform communication with programmable

controllers.

For details of the CC-Link IE controller network connection, refer to GOT1000

Series Connection Manual.

Item Specification

Max. link points

per network

LB 32K points (32768 points, 4KB)

LW 128K points (131072 points, 256KB)

LX 8K points (8192 points, 1KB)

LY 8K points (8192 points, 1KB)

Max. link points

per station

LB 16K points (16384 points, 2KB)

LW 16K points (16384 points, 32KB)

LX 8K points (8192 points, 1KB)

LY 8K points (8192 points, 1KB)

Transient transmission

capacity Up to 1920 bytes

Communication speed 1Gbps

Communication method Token ring

Number of stations per

network

Up to 120 stations

(Control station: 1, Normal station: 119) *1

Connection cable Fiber-optic cable (Multi-mode fiber)

( CC-Link IE Controller Network Reference Manual)

Overall cable distance 66000m (When 120 stations are connected)

Station-to-station

distance (Max.) 550m (Core/Clad = 50/125 ( m))