Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan Date of publication: December 1, 2021

Printed in Japan

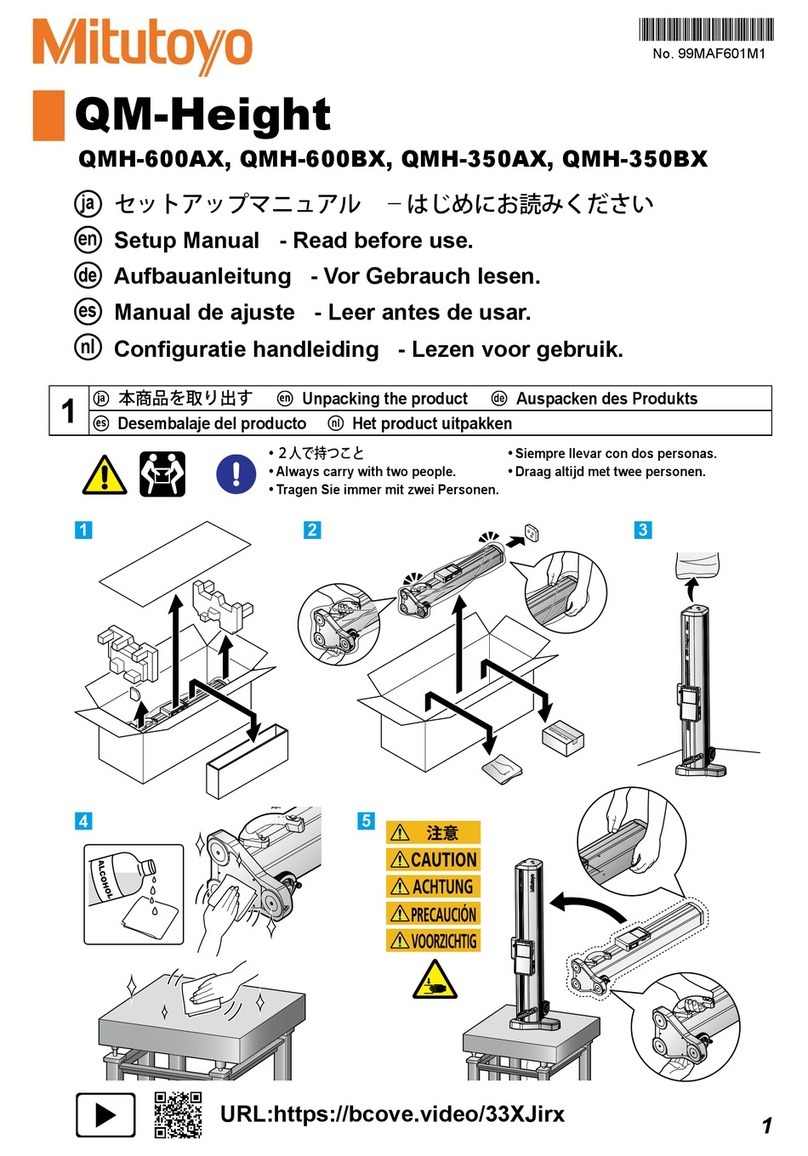

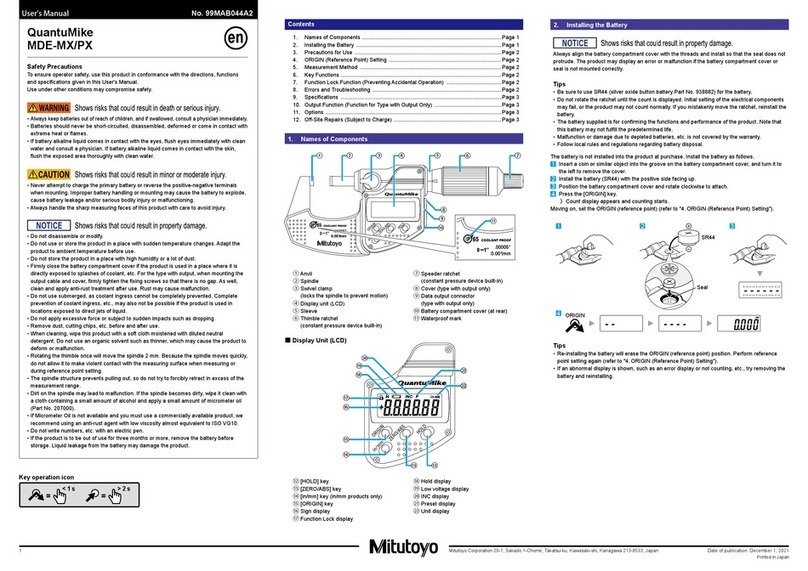

2. Installing the Battery

Tips

• Be sure to use SR44 (button type silver-oxide battery Part No. 938882) for the battery.

• Do not rotate the thimble until the count is displayed. Initial setting of the control unit may fail and the product may

not count normally. If you mistakenly move the thimble, reinstall the batteries.

• The batteries supplied are for conrming the functions and performance of the product. Note that these batteries

may not fulll the predetermined life.

• Malfunction or damage due to depleted batteries, etc. is not covered by the warranty.

• Follow local rules and regulations regarding battery disposal.

The batteries are not installed into the product at purchase. Install the batteries as follows.

1 Use the supplied Phillips screwdriver (No.05CAA952) to loosen the battery compartment cover xing screw

(No.04GAB130), and then remove the battery compartment cover.

2If replacing the existing batteries, remove the old batteries.

3Install the batteries (SR44) with the positive side facing up.

4 Place the battery compartment cover over the battery compartment and hold down the edge with your ngers while

making sure there is no gap between the cover and body, and then tighten it using the screw.

》The "------" display blinks.

5Press the [PRESET] key.

》Count display appears and counting starts.

1 3

4

5PRESET

SR44 x 2

Tips

• Reinstalling the batteries will erase the PRESET value (reference point). Perform reference point setting again (see

"5. PRESET Value (Reference Point) Setting".

• If an abnormal display that indicates an error or counting failure, etc., is shown, try removing the batteries and

reinstalling.

Key operation icon

=

> 2 s

=

< 1 s

3. Precautions for Use

■Measuring Force

• Use the ratchet stop to ensure consistent measuring force.

• The appropriate measuring force is achieved with the following procedure:

bring the measurement surfaces and the workpiece into light contact with

each other, stop momentarily, and then manually turn the ratchet stop

about three to ve times.

■Precautions for Measurement

• Use caution when measuring magnetized workpieces. If the product

becomes magnetized, measurement results may be affected.

■Precautions after Use

• After use, clean the entire product and check that none of the parts

are damaged.

If using in places exposed to water-based cutting uid, always apply

anti-rust treatment after cleaning.

• For storage, leave a gap of 0.2 to 2 mm open for the measurement

surfaces, and release the swivel clamp.

• If the product will not be used for three months or longer, apply

micrometer oil (Part No. 207000) to the spindle to prevent rust, and

store it with its battery removed.

• If Micrometer Oil is not available and you must use a commercially available product, we recommend using an anti-rust

agent with low viscosity almost equivalent to ISO VG10.

4. Interchangeable Anvil Replacement Method (340 Series Only)

Install the interchangeable anvil for the 340 series and then measure.

1 See the following conversion table and select the specied interchangeable anvil that matches the length of the

workpiece.

Conversion table

Measuring range

[mm]

Measuring range for each anvil sign

[mm]

M3 M4 M5 M6

300–400 300–325 325–350 350–375 375–400

400–500 400–425 425–450 450–475 475–500

500–600 500–525 525–550 550–575 575–600

600–700 600–625 625–650 650–675 675–700

700–800 700–725 725–750 750–775 775–800

800–900 800–825 825–850 850–875 875–900

900–1000 900–925 925–950 950–975 975–1000

Measuring range

[in]

Measuring range for each anvil sign

[in]

M1 M2 M3 M4 M5 M6

12"–18" 12"–13" 13"–14" 14"–15" 15"–16" 16"–17" 17"–18"

18"–24" 18"–19" 19"–20" 20"–21" 21"–22" 22"–23" 23"–24"

24"–30" 24"–25" 25"–26" 26"–27" 27"–28" 28"–29" 29"–30"

30"–36" 30"–31" 31"–32" 32"–33" 33"–34" 34"–35" 35"–36"

Tips

Be aware that the M6 interchangeable anvil does not have a sign on the anvil itself.

<Example> When switching from interchangeable anvil sign M4 to M5

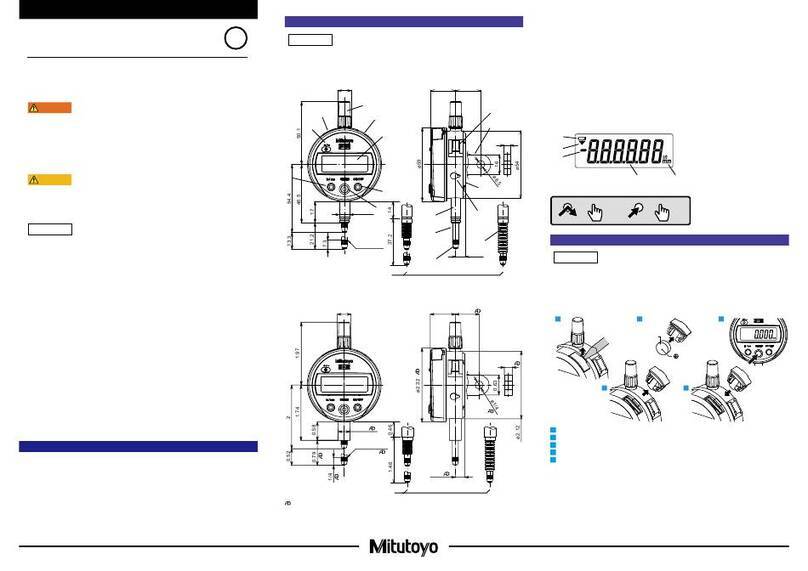

2Loosen the tightening screw and remove the

interchangeable anvil (M4).

Rotate about three

to ve times.

Release swivel clamp.

M4

2

Tightening screw

Interchangeable anvil sign

Interchangeable anvil

3Cleanly remove the dirt from surface A of the anvil

bush and surface B of the selected interchange-

able anvil (M5).

4Align the marking of the interchangeable anvil with

the marking of the anvil bush, and secure them with

the tightening screw.

5Use the standard bar to set the reference point

and begin measuring (see "5. PRESET Value

(Reference Point) Setting").

5. PRESET Value (Reference Point) Setting

Set an arbitrary preset value (reference point registration) prior to setting the reference point.

• For reference point setting, use a periodically inspected (calibrated) gage (gauge block, setting standard

for outside micrometer, etc.).

• Reference point setting and measurement should be made in the same orientation and conditions with

the procedure as below.

1) Reference point registration

Register (preset) zero or gage dimensions such as a standard bar, etc. to this product. Two preset values (P1 and P2)

can be registered to the product.

Tips

Press and hold the [HOLD] key to switch between P1 and P2.

<Example> Registering 300.000 mm to P1

1 Briey press the [PRESET] key.

》The previously registered number is displayed and [P1] blinks.

Tips

• Zero will be displayed immediately after replacing the batteries.

• If [P2] is blinking, press and hold the [HOLD] key to cause [P1] to blink.

2Press and hold the [PRESET] key.

》The sign blinks.

Tips

Briey press the [PRESET] key to switch between [+] and [-].

3Press and hold the [PRESET] key.

》The leftmost number blinks.

Tips

The numbers will switch in order from [0] to [1] to [2] up to [9] and

then [0] each time the [PRESET] key is briey pressed.

M5

3A

B

Anvil bush

M5

M5

M5

4Marking

3

2

1

PRESET

PRESET

2