Printed in Japan

Mitutoyo Corporation 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533

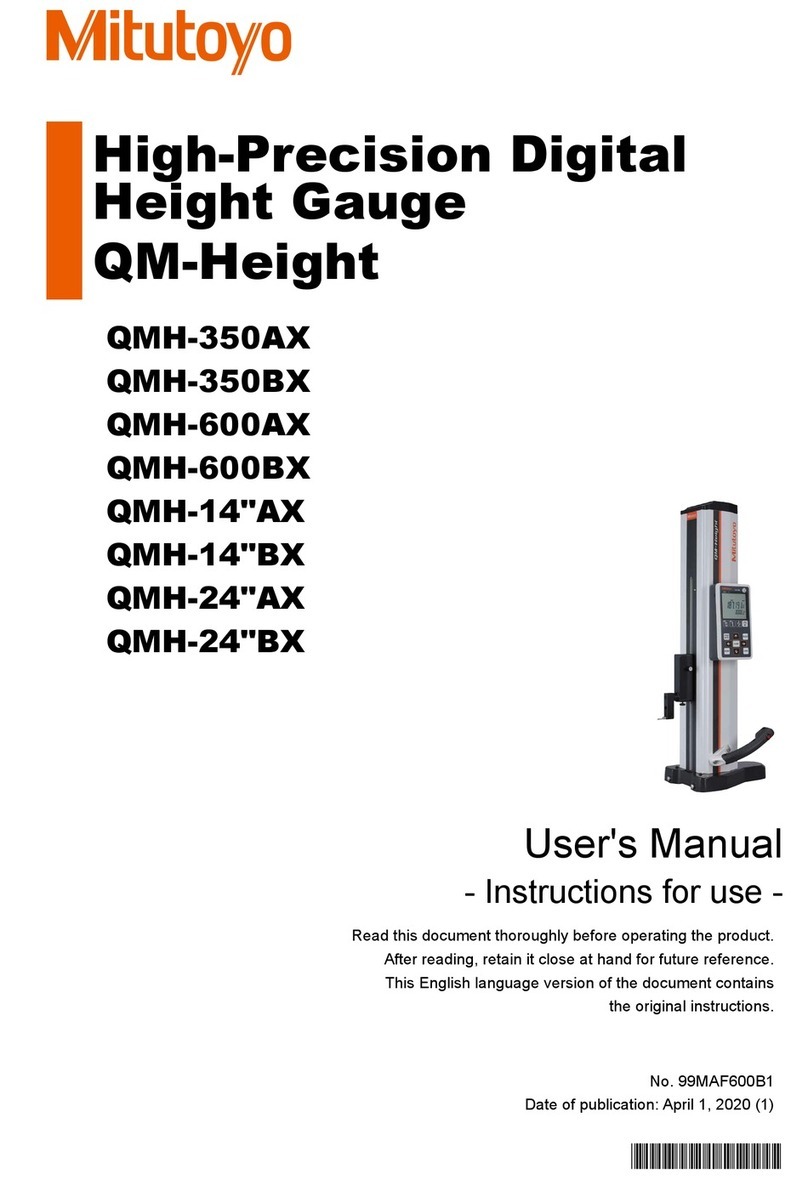

ABS Digimatic Indicator ID-SX

Contents

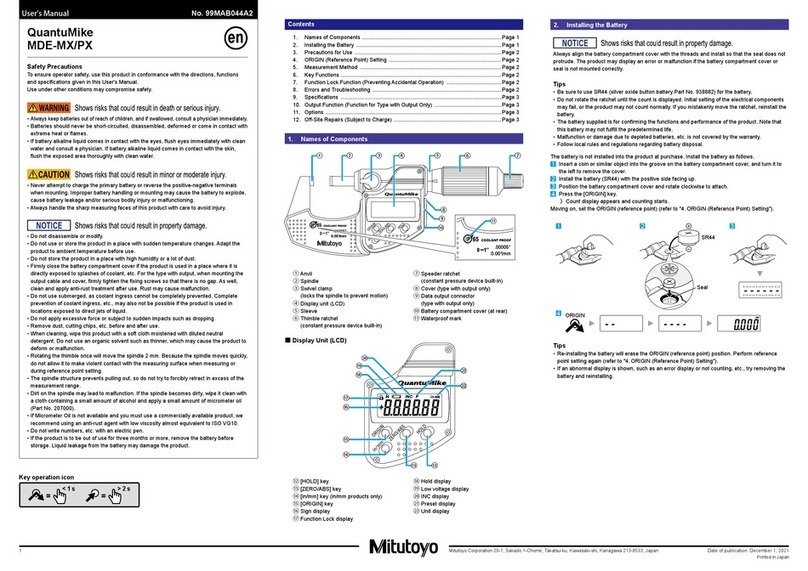

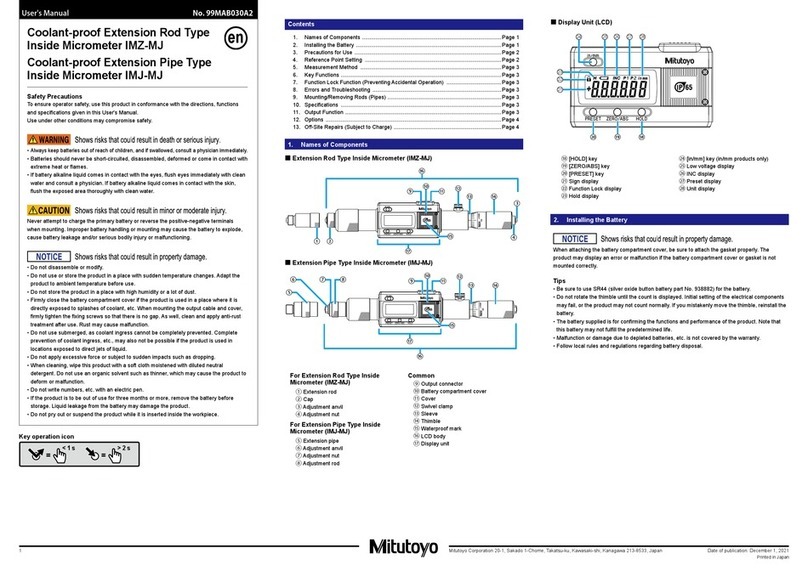

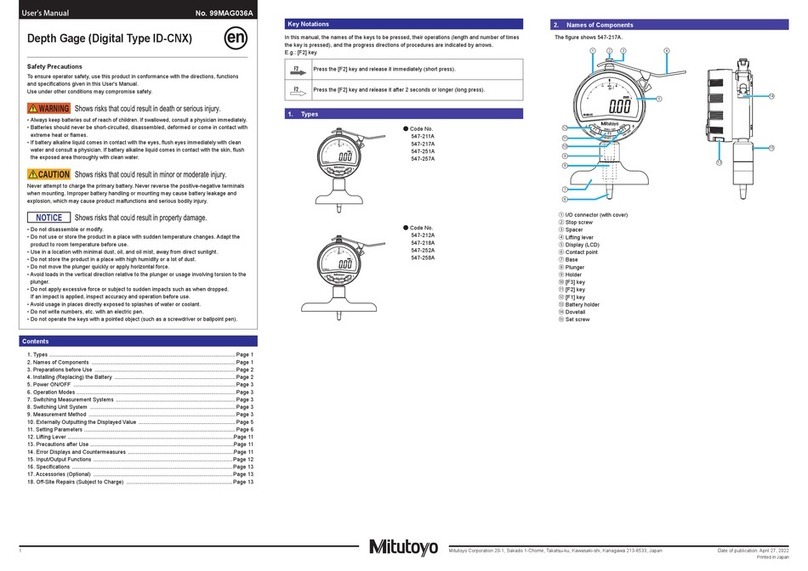

①Cap

②Battery holder

③Display (LCD)

④[ON/OFF] key

⑤[ORIGIN] key

⑥[in/mm] key (except for ID-S1012X,

ID-S112X, ID-S112PX)

⑦[+ / -] key

⑧Output connector (with cap)

⑨Lifting lever mount (left and right)

⑩Back with lug

⑪Flat back

⑫Release mounting hole (with rubber cap)

⑬Stem

⑭Spindle

⑮Contact point

⑯Rubber boot (dustproof type only)

Tips

Dimensions with an asterisk (*) are for the at back type. Dimensions without an asterisk (*) are

common for the back with lug type and the at back type.

■ Display (LCD)

Key icon operation

=

> 2 s

=

< 1 s

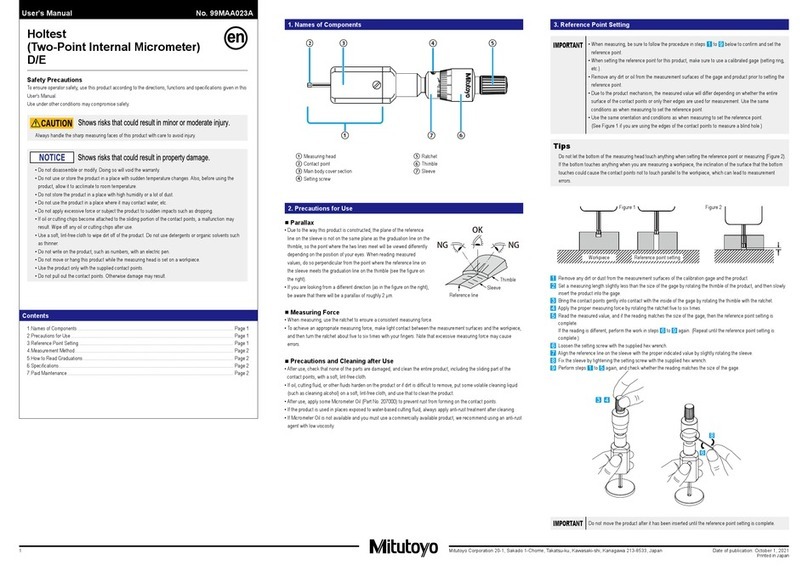

2. Installing (Replacing) the Battery

• Be sure to use SR44 (silver oxide button battery No. 938882) for the battery.

• The product may display an error or malfunction if the battery holder is not mounted correctly.

• If the product will be out of use for 3 months or more, remove the battery and store it

separately, to prevent damage to the product due to battery uid leakage.

• Do not use a pointed object or excessive force to remove the battery holder. This may damage

the battery holder.

SR44

31 5

2 4

1 Use a athead screwdriver or similar to remove the battery holder.

2 If replacing an existing battery, remove the old battery.

3 Insert a new battery into the battery holder with the "+" symbol facing the display (LCD).

4 Attach the battery holder.

5 Press the [ORIGIN] key for 1 second or more.

Tips

• If no value is displayed even when a battery is installed, reinstall the battery.

• Although the display may show garbled text, [E] (minimum digits) or [------] just after installing

the battery, this is not abnormal. Perform reference point setting as is (refer to "5. ORIGIN

Setting (Reference Point Setting)").

• Reference point settings are cleared when the battery is removed. Perform reference point

setting again after installing the battery.

①Unit display

②Measured value display

③Sign display

④Reverse count display

⑤Battery voltage decrease

display

Safety Precautions

To ensure operator safety, use this product in conformance with the directions, functions

and specications given in this User's Manual.

Use under other conditions may compromise safety.

• Always keep batteries out of reach of children, and if swallowed, consult a physician im-

mediately.

• Batteries should never be short-circuited, disassembled, deformed or come in contact with

extreme heat or flames.

• If battery alkaline liquid comes in contact with the eyes, flush eyes immediately with clean

water and consult a physician. If battery alkaline liquid comes in contact with the skin,

flush the exposed area thoroughly with clean water.

• Never attempt to charge the primary battery or reverse the positive-negative terminals

when mounting. Improper battery handling or mounting may cause the battery to explode,

cause battery leakage and/ or serious bodily injury or malfunctioning.

• Always handle the sharp measuring faces of this product with care to avoid injury.

• Do not disassemble or modify. This may cause damage.

• Do not use or store the product in a place with sudden temperature changes. Adapt the

product to room temperature before use.

• Do not store the product in a place with high humidity or a lot of dust. Also, avoid usage in

places exposed to splashes of water or coolant.

• Do not apply excessive force or subject to sudden impacts such as dropping.

• Be sure to perform reference point setting before measurement.

• Remove dust, cutting chips, etc. before and after use.

• Do not write numbers, etc. with an electric pen. This may cause damage.

• Do not operate the keys with a pointed object (such as a screwdriver or ballpoint pen).

•

Avoid loads in the vertical direction relative to the spindle or usage involving torsion to the spindle.

• This product is shipped without a battery. Install a battery before use.

• The battery supplied is for conrming the functions and performance of the product. Note

that this battery may not fulll the expected life.

• When disposing of batteries, follow local laws, regulations, etc.

• Malfunction or damage due to depleted batteries, etc. is not covered by the warranty.

• The dustproof type protects the spindle and bearing from dust, water, oil, etc. by attaching

a rubber boot, etc. to the standard type. Note that the dustproof type is not completely

waterproof. Do not immerse the product in liquid or use the product in a place where it is

intensively exposed to oil or water.

• In environments with large temperature fluctuations, the measurement errors will increase

due to thermal expansion of parts and fixtures. Therefore use the product where the

temperature fluctuation is as little as possible.

When it is moved to a different temperature environment, allow sufficient time for the

product to thermally stabilize before use.

User's Manual No. 99MAH032A2

Date of publication: November 1, 2020

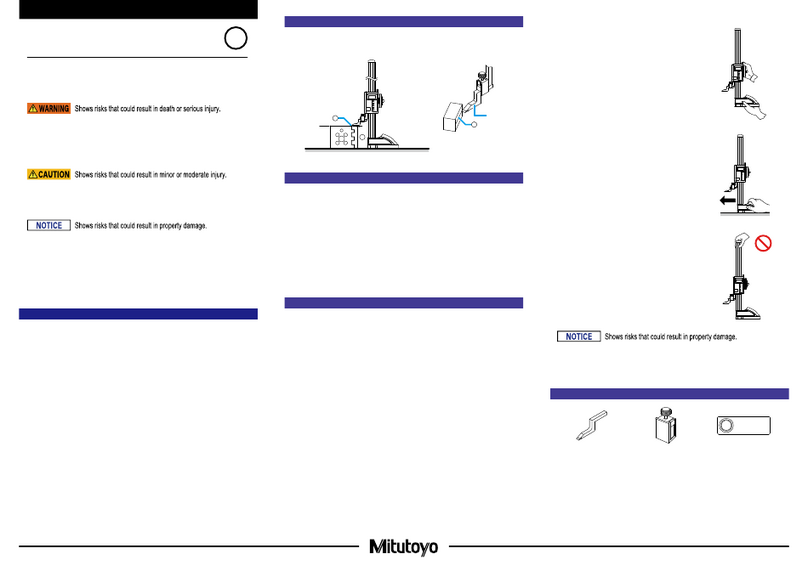

1. Names and Dimensions of Components

The product display does not rotate. Forcibly rotating the display may damage the product.

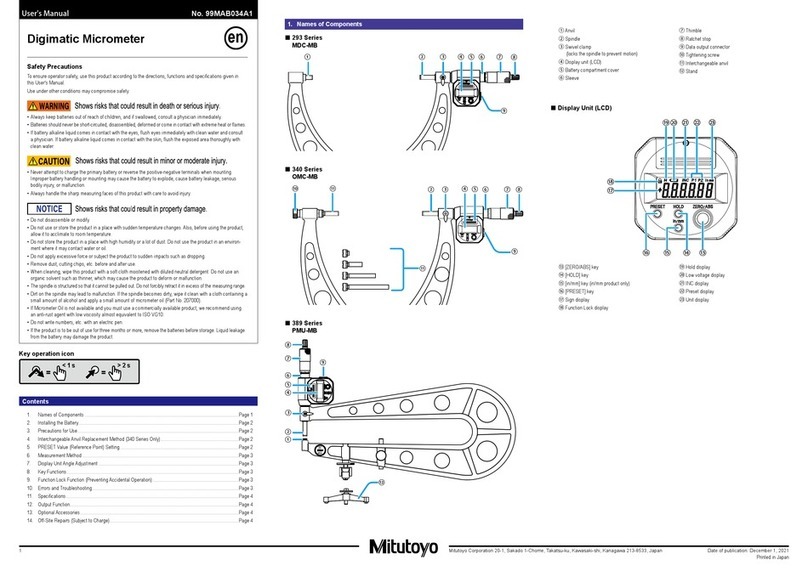

■ ISO/JIS type

Back with lug type: ID-S1012X, -S1012MX, -S112X, -S112MX, -S112PX, -S112PMX

Flat back type*: ID-S1012XB, -S1012MXB, -S112XB, -S112MXB, -S112PXB, -S112PMXB

Unit: mm

Dustproof type

①

⑪

⑬

⑭

⑮

⑨

③

②

⑫

ø

6.5

M2.5x0.45

*

ø59

46.5

21.2

7.3

ø80

-0.009

7.6

50.1

5

16

17

ø54

⑯

⑩

⑧

⑦

⑤

④

ID-S112PX, ID-S112PXB,

14

37.2

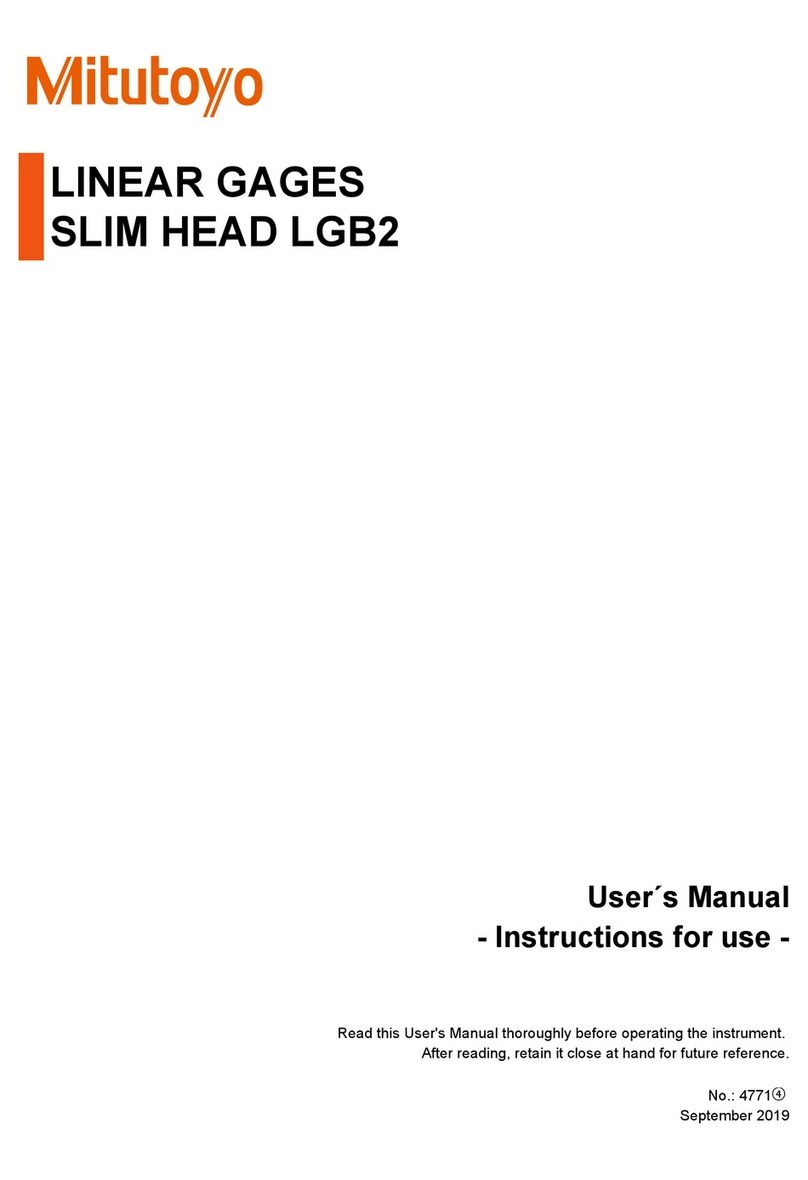

■ AGD type

Back with lug type: ID-S1012EX, -S112EX, -S112TX, -S112PEX

Flat back type*: ID-S1012EXB, -S112EXB, -S112TXB, -S112PEXB

Dustproof type

ø1/4

Thread

No.4-48UNF

3/8

ø2.32

0.58

0.46

1.97

0.3*

1/4

ø9.52 mm

1/4

1.74

0.79

0

-0.03

ø2.12

0.63

3/4

0.78

1.46

Unit: in

This is the symbol of American Gage Design (AGD). It means that this type conforms to

appropriate dimensions of Dial Indicators in ASME/AGD 2 and has interchangeability.

1.

Names and Dimensions of Components ......1

2. Installing (Replacing) the Battery .......... 1

3. Setup .................................................... 2

4. Power ON/OFF ..................................... 2

5. ORIGIN Setting ..................................... 2

(Reference Point Setting)

6. Measurement Method ........................... 3

7. Precautions after Use ........................... 3

8. Errors and Troubleshooting .................. 3

9. Rubber Boot Replacement .................. 3

(ID-S112PX, ID-S112PXB)

10. Output Function .................................... 3

11. Specications........................................ 4

12. Accessories (Optional).......................... 4

13. O-Site Repairs (Subject to Charge) .... 4