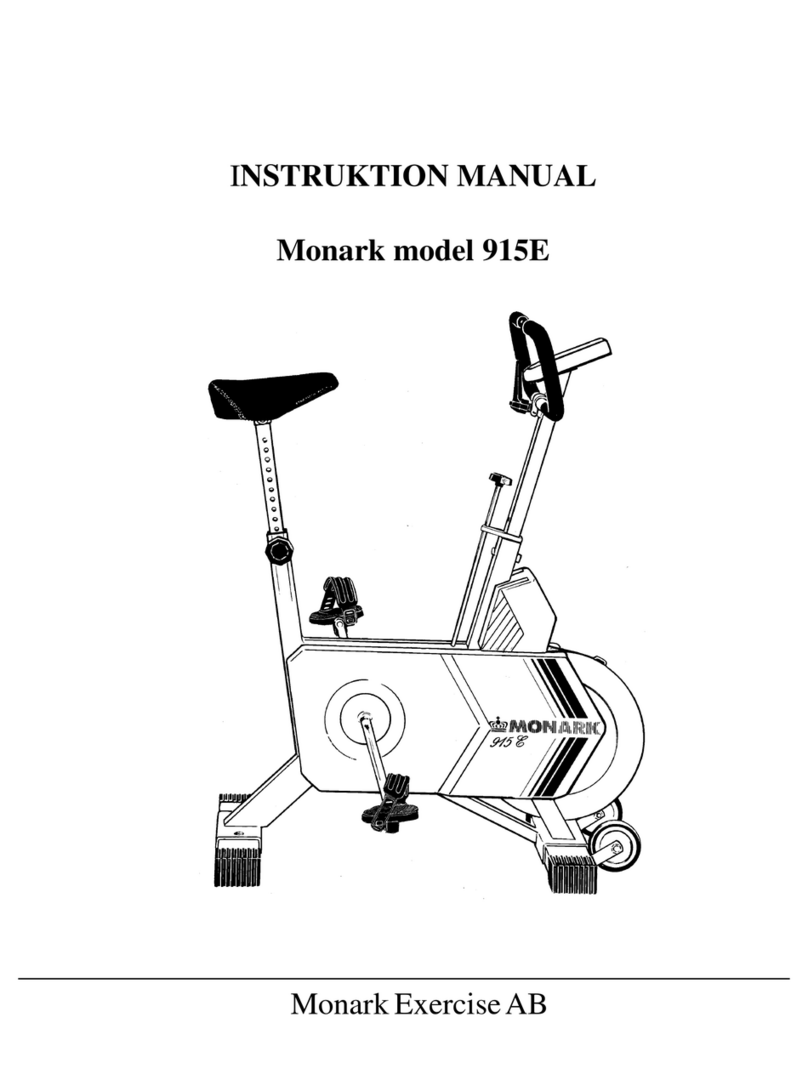

Monark Exercise AB����������������������������������������������������������������������4

Product Information ����������������������������������������������������������������������5

Serial number��������������������������������������������������������������������������������������������� 5

Facts����������������������������������������������������������������������������������������������������������� 5

PC software������������������������������������������������������������������������������������������������ 5

Operating Instruction��������������������������������������������������������������������6

Power on crank or ywheel ������������������������������������������������������������������������ 6

Operation of the ergometer ������������������������������������������������������������������������ 6

Measured quantities����������������������������������������������������������������������������������� 6

Rpm meter with optical pulse / metronome������������������������������������������������ 7

Calories ������������������������������������������������������������������������������������������������������ 7

Initial operation������������������������������������������������������������������������������������������� 7

Cycle adjustments�������������������������������������������������������������������������������������� 7

Connection to controller���������������������������������������������������������������8

Setting command type (PC or ECG device)����������������������������������������������� 8

What command type is set?����������������������������������������������������������������������� 8

Procedure when connecting to the ������������������������������������������������������������ 8

handheld controller������������������������������������������������������������������������������������� 8

Connection to PC ��������������������������������������������������������������������������������������� 9

Connecting an external ECG device with digital control��������������������������� 10

Analogue connection�������������������������������������������������������������������������������� 11

Printer������������������������������������������������������������������������������������������������������� 11

Calibration������������������������������������������������������������������������������������12

Validation�������������������������������������������������������������������������������������������������� 12

Checking the pulse function ��������������������������������������������������������������������� 12

Validation of force������������������������������������������������������������������������������������� 13

Electronic calibration �������������������������������������������������������������������������������� 13

Electronic calibration - with handheld controller��������������������������������������� 14

Electronic calibration - PC������������������������������������������������������������������������ 14

Electronic calibration - with the pendulum������������������������������������������������ 14

Calibration ������������������������������������������������������������������������������������������������ 16

Zero adjustment of scale�������������������������������������������������������������������������� 16

Testing with Ergomedic 839 E����������������������������������������������������17

Heart Rate (telemetry)������������������������������������������������������������������������������ 18

Test person enforcement�������������������������������������������������������������������������� 18

Reviewing results ������������������������������������������������������������������������������������� 19

Troubleshooting guide����������������������������������������������������������������20

Operation interferences���������������������������������������������������������������������������� 21

Where to obtain additional information ������������������������������������22

Service������������������������������������������������������������������������������������������24

Warning ���������������������������������������������������������������������������������������������������� 24

Warranty��������������������������������������������������������������������������������������������������� 24

Service check and Maintenance �������������������������������������������������������������� 24

Batteries ��������������������������������������������������������������������������������������������������� 25

Flywheel bearing �������������������������������������������������������������������������������������� 25

Crank bearing������������������������������������������������������������������������������������������� 25

Transportation ������������������������������������������������������������������������������������������ 25

Replacement of brake belt ����������������������������������������������������������������������� 25

Brake belt contact surface������������������������������������������������������������������������ 25

Chain 1/2“ x 1/8“��������������������������������������������������������������������������������������� 26

Freewheel sprocket���������������������������������������������������������������������������������� 27

Spare parts list ����������������������������������������������������������������������������28

2014 MONARK EXERCISE AB, Vansbro, Sweden

Contents