Moog MSD C2 User manual

C2 to C5

2.0 A to 16.0 A

MSD Servo Drive

Operation Manual

Single-Axis Servo Drive Compact

moog

2

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

MSDSingle-Axis Servo Drive Compact high-performance drives

The modularity of the MSD Single-Axis Servo Drive Compact guarantees you optimum

integration into the machine process. Whether in high-speed eld bus communication

with the central multi-axis machine controller or with distributed programmable Motion

Control intelligence in the servo drive, the MSD Single-Axis Servo Drive Compact is a

master of both.

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.: CA97555-001, Rev. 5.3

Date: 04/2018

Applicable as from firmware version:V1.25-01

The German version is the original of this Operation Manual.

We reserve the right to make technical changes.

This Operation Manual has been prepared based on DIN EN 82079-1. The content

was compiled with the greatest care and attention, and based on the latest information

available to us.

We should nevertheless point out that this document cannot always be updated in line

with ongoing technical developments in our products.

Information and specications may be subject to change at any time. For information on

the latest version please visit drives-support@moog.com

C2 C3 C4 C5

3

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

Table of contents

1 General .................................................................................... 5

1.1 Target group ............................................................................................................. 5

1.2 Prerequisites ............................................................................................................. 5

1.3 Reference documents .............................................................................................. 5

1.4 Order code ............................................................................................................... 6

1.5 Production data ........................................................................................................ 6

1.6 Scope of supply........................................................................................................ 6

1.7 Pictograms ............................................................................................................... 7

1.8 Disclaimer ................................................................................................................. 7

1.9 Disposal ................................................................................................................... 7

1.10 Helpline/Support & Service Center ........................................................................... 7

2 Safety ...................................................................................... 9

2.1 O v e r vi ew .................................................................................................................. 9

2.2 For your safety .......................................................................................................... 9

2.3 General safety instructions and warnings ................................................................10

2.4 Intended use ............................................................................................................ 10

2.4.1 Repair ............................................................................................................ 11

2.5 Usage contrary to intended use...............................................................................11

2.6 Responsibility ..........................................................................................................11

2.7 Relevant laws, standards and directives applied .....................................................11

2.8 Declaration of conformity .........................................................................................12

3 Mechanical installation ........................................................... 13

3.1 Notes for operation .................................................................................................. 13

3.2 Wall mounting .......................................................................................................... 13

3.2.1 Dimensions of the devices .............................................................................14

3.2.2 Mounting clearances .....................................................................................15

4 Electrical installation ............................................................... 17

4.1 Notes for installation ................................................................................................17

4.2 Layout .....................................................................................................................18

4.3 Connection diagram C2 to C4 .................................................................................20

4.4 Connection diagram C5 ..........................................................................................21

4.5 Effective EMC installation ....................................................................................... 22

4.5.1 Interference immunity of Servo Drives .......................................................... 22

4.5.2 Specimen setup ........................................................................................... 22

4.6 Protective earth conductor connection....................................................................25

4.7 Electrical isolation concept ......................................................................................26

4.8 Connection of the supply voltages ..........................................................................27

4.8.1 Connection of control supply (+24VDC) .......................................................27

4.8.2 Connection of mains supply .........................................................................28

4.8.3 Connected load and mains fuse ................................................................... 29

4.9 Control connections ................................................................................................31

4.9.1 Specication of control connections .............................................................31

4.9.2 Connection of motor brake X13 .................................................................... 32

4.10 Specication, Ethernet interface ............................................................................. 33

4.11 O pti o n 1 .................................................................................................................. 33

4.12 Option 2 .................................................................................................................. 33

4.13 Encoder connection ............................................................................................... 34

4.13.1 Ready made encoder cables ....................................................................... 34

4.13.2 Resolver connection X6 ................................................................................ 35

4.13.3 Connection for high-resolution encoder ....................................................... 36

4.14 Motor connection ....................................................................................................37

4.14.1 Motor temperature sensor .............................................................................37

4.14.2 Connection of the servo motors ................................................................... 38

4.14.3 Switching in the motor cable ........................................................................ 40

4

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

4.15 Brake chopper connection ..................................................................................... 40

4.15.1 Protection in case of brake chopper fault ..................................................... 40

4.15.2 Design with integrated braking resistor (C3+4+5) ......................................... 40

4.15.3 Connection of an external braking resistor ....................................................42

5 Commissioning ...................................................................... 45

5.1 Notes for operation ................................................................................................. 45

5.2 Initial commissioning .............................................................................................. 45

5.2.1 Switching on control supply ......................................................................... 46

5.2.2 Establishing connection between PC and servo drive .................................... 46

5.2.3 Setting parameters ....................................................................................... 46

5.2.4 Controlling drive using Moog DriveADministrAtor5 ....................................... 46

5.3 Serial commissioning .............................................................................................. 48

5.4 Integrated control unit ............................................................................................. 48

5.4.1 Function of buttons T1 and T2...................................................................... 49

5.4.2 Display .......................................................................................................... 50

5.4.3 Parameter menu (PA).................................................................................... 50

5.4.4 Error numbers .............................................................................................. 50

5.4.5 Ethernet IP address menu (IP) .......................................................................51

5.4.6 Field bus address menu (Fb) .........................................................................52

6 Diagnostics ............................................................................ 55

6.1 Device states .......................................................................................................... 55

6.2 Error indication ....................................................................................................... 55

6.3 Error codes ............................................................................................................. 55

6.4 Helpline/Support&Service .................................................................................... 56

7 Safe Torque Off (STO) ............................................................ 57

A Appendix ............................................................................... 59

A.1 Servo drive current loads ........................................................................................ 59

A.2 Technical data MSD Single-Axis Servo Drive Compact .......................................... 62

A.3 Ambient conditions ................................................................................................. 64

A.4 UL certication ....................................................................................................... 65

Glossary ........................................................................................ 67

5

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

1 General

The product CD from Moog contains the complete documentation for the related

product series. The documentation for a product series includes the Operation Manual

(hardware description), Device Help (software description) as well as further User

Manuals (e.g. field bus description) and Specifications. They are available in the formats

PDF, HTML or chm.

1.1 Target group

Dear user,

the documentation forms part of the device and contains important information on

operation and service. It is aimed at all persons who undertake mounting, installation,

commissioning and servicing work on the product.

1.2 Prerequisites

Prerequisites for the usage of devices from Moog:

yThe documentation on the devices is to be stored so it legible, accessible at all times and for the

entire life of the product.

yRead and ensure you under Date the documentation on your device.

yQualication: to prevent injury or damage, personnel may only work on the device if they have

electrical engineering qualications.

yKnowledge required:

− National health and safety regulations (e.g. VBG 4 in Germany)

− Mounting, installation, commissioning and operation of the device

Work in other areas, for example transport, storage and disposal is only allowed to be

undertaken by trained personnel.

NOTE

This Operation Manual applies to the MSD Single-Axis Servo Drive Compact

(referred to in the following as the servo drive). This manual does not replace the

Operation Manuals for the MSD Single- and Multi-Axis Servo Drive.

1.3 Reference documents

Document Contents ID no.

Format

MSD Servo Drive

Single-Axis Servo Drive

Compact - Operation Manual

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specifications certification and

applicable standards, technical data

CA97555-001

PDF

MSD Servo Drive

AC-AC Servo Drive

Single-Axis System -

Operation Manual

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specifications certification and

applicable standards, technical data

CA65642-001

PDF

MSD Servo Drive

DC-AC Servo Drive

Multi-Axis System-

Operation Manual

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, STO, operation with AC-AC Servo Drive as supply,

planning, application example, specifications certification and

applicable standards, technical data

CA97554-001

PDF

MSD Power Supply Unit

Multi-Axis System-

Operation Manual

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, specification certification and applicable standards

technical data

CA97556-001

PDF

MSD Servo Drive

SERCOS II -

User Manual

Safety, commissioning, communication phases, parameter interface,

error, warning and status messages, operation modes, weighting,

referencing, touchprobe, parameter lists

CA65648-001

PDF

MSD Servo Drive

SERCOS III -

User Manual

Safety, installation and connection, commissioning and configuration

parameterisation, data transmission, scaling and weighting,

functionality, error message and diagnostics, parameter lists

CA97557-001

PDF

MSD Servo Drive Field bus

systems CANopen/EtherCAT -

User Manual

Safety, commissioning, data transmission, operation modes,

referencing, parameters, technical data CA65647-001

MSD Servo Drive

Field bus systems

Profibus/Profine

User Manual

Description and configuration of the parameters for the MSD Se vo

Drive on the PROFIBUS/PROFINET field bus syste

CA65645-001

PDF

Modular Multi-Axis Servo

Drive System - MSD -

Ordering Catalog

Information, notes on ordering, specifications and

technical data on:

MSD Single-Axis Servo Drive Compact, MSD Single-Axis System,

MSD Multi-Axis System, safety technology, communication,

technology, function packages, accessories and motors

CDL 29950-en

PDF

MSD Servo Drive - Device

Help

Description of the software functionality MSD Servo Drive,

firmware versions

- MSD Single-Axis Servo Drive Compact from V1.30-xx

- MSD Single-Axis System from V3.25-xx

- MSD Multi-Axis System from V3.25-xx

CB40859-001

PDF and

HTML

Program help

Moog DriveADminsitrAtor 5

PC user software

Context-sensitive help for Moog DriveADministrAtor version 5.x

graphic PC user software for initial commissioning and serial

commissioning, operation, diagnostics and project management

CB19692-001

6

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

1.4 Order code

The MSD Single-Axis Servo Drive Compact has the article designation

G394-xxx-xxx-xxx. The provides information on the related variant of the supplied

MSD Servo Drive. The signicance of the individual characters of the article designation

is given in the following order code.

You will nd the complete order code with all values in the MSD Ordering Catalog.

1.5 Production data

On rating plates for the MSD Single-Axis Servo Drive Compact you will nd the serial

number, from which you can identify the date of manufacture based on the following

key. For the location of the rating plate on the servo drive refer to "Figure 4.1 Layout

MSD Single-Axis Servo Drive Compact C2 to C4" and "Figure 4.2 Layout MSD Single-

Axis Servo Drive Compact C5".

Model:: G394-030-210-001

In: 230 V AC 3ph, 50/60 Hz

4,0 A

0-230 V AC 3ph, 0-400 Hz

3,0 A

Out:

MOOG

D-71034 Böblingen

www .moog.com/industrial

Made in Germany

S/N:D116605 Rev. A

ID : JJWWxxxxx

Year of production

Week of production

Fig. 1.1 MSD Single-Axis Servo Drive Compact hardware rating plate

1.6 Scope of supply

The scope of supply includes:

yMSD Single-Axis Servo Drive Compact

yTerminal kit for control and power terminals

y

y

(depending on device power and variant)

Set with shield connecting plates and xing material

Product CD with booklet

G394 -- -

Rated current

Option 1 (Communication)

Option 2 (Technology)

Option 3 (Safety)

Option 4 (Function package)

Modificatio

Variants

7

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

1.10 Helpline/Support & Service Center

Our Helpline will help you with fast, specic assistance if you have any technical queries

relating to project planning or commissioning your device.

Address: Moog GmbH

Hanns-Klemm Straße 28

D-71034 Böblingen

The Helpline is available by e-mail, telephone or telefax:

E-Mail: drives-support@moog.com

Phone: +49 7031 622 0

Telefax: +49 7031 622 100

If you need further assistance, our specialists at the Service & Support Center will be

happy to help.

E-Mail: info.germany@moog.com

Phone: +49 7031 622 0

1.7 Pictograms

The pictograms used in this Operation Manual signify the following for the user:

NOTE

Useful information or reference to other documents.

1.

(digit)

ACTION TO BE TAKEN

Processing step undertaken by the user or the system.

You will nd the pictogram used in this Operation Manual for "General safety instruc-

tions and warnings" in chapter "2 Safety".

1.8 Disclaimer

Following the documentation on the devices from Moog GmbH is a prerequisite:

yFor safe operation.

yTo achieve stated performance features and product characteristics.

Moog GmbH does not accept any liability for injuries, damage or nancial losses that

result from the failure to follow the documentation.

1.9 Disposal

Follow the applicable national regulations! If necessary, dispose of individual parts,

depending on their characteristics and existing national regulations, e.g. as:

yElectrical waste

yPlastic

yMetal

Or engage a certied disposal organisation with scrapping

8

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

9

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

2 Safety

2.1 Overview

Our devices are state-of-the-art and comply with recognised safety regulations,

nevertheless hazards can arise. In this chapter:

yWe provide information on residual risks and hazards that can emanate from

our devices on usage as intended.

yWe warn about the foreseeable misuse of our devices.

yWe refer to the necessary care and measures to be taken to prevent risks.

2.2 For your safety

NOTE

Only install and place in operation your device taking into account the

documentation for the related device family!

Our devices are quick and safe to operate. For your own safety and for the safe

functioning of your device, please be sure to observe the following points:

1. Follow safety instructions for the devices:

Follow all safety instructions and warnings in the entire documentation related to the device series.

2. Electric drives are dangerous:

• Due to electrical voltages up to 480V AC and up to 800 V DC

• Dangerously high voltages of ≥50V may still be present 10min. after the power is cut

(capacitor charge). So check that electrical power is not present! See also the warning label on

the front panel on the device.

• Rotating parts

• Automatically starting drives.

• Hot components and surfaces

3. Protection against magnetic and/or electromagnetic fi lds during

installation and operation.

Persons tted with heart pacemakers, metallic implants and hearing aids etc. must not be allowed

access to the following areas:

• Areas in the immediate vicinity of electrical equipment!

• Areas in which electronics components and Servo Drives are installed,

repaired and operated!

• Areas where motors are installed, repaired and operated!

Motors with permanent magnets pose particular hazards.

4. During installation observe the following:

• Comply with connection conditions and technical data as per the documentation and the

rating plate!

• Comply with standards and directives on electrical installation, such as cable cross-section,

shielding, etc.!

• Do not touch electronic components and contacts!

Electrostatic discharge can harm people and destroy components!

• Take protection measures and use protective devices as per the applicable regulations

(e.g. IEC/EN60204 or IEC/EN 61800-5-1)!

• Take "device earthing" protection measure!

5. Ambient conditions

• Follow the instructions on the transport, storage and correct operation of the devices stated in

the Operation Manual in "A Appendix".

10

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

2.3 General safety instructions and warnings

Hazards may emanate from our devices. For this reason it is imperative you follow the

safety instructions and warnings in this document.

DANGER! Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to electrical power!

• Carelessness may result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

CAUTION! Risk of injury or damage to the device due to incorrect operation!

• Carelessness may result in minor injuries or

damage.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to hot surfaces and components!

• Carelessness may result in serious burns.

Electronic components may become hot during operation!

Follow safety instructions and warnings in this document and on the device!

Caution! Damage due to electrostatic discharge!

• Electrostatic discharge can destroy components.

Do not touch electronic components and contacts!

Follow safety instructions and warnings in this document and on the device!

DANGER! Risk of injury due to rotating parts on the motor!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document.

Pay attention to special safety instructions and warnings that are given here in the document

before a specic action and that warn the user about a specic hazard!

NOTE:

The pictograms may also be used on their own with the signal word, e.g.

in the connection diagrams, however they have the same function as in the

complete warning.

DANGER WARNING CAUTION

2.4 Intended use

Our devices are components intended for stationary electrical systems and machines in

the industrial and commercial sector.

The devices in the product range MSD Single-Axis Servo Drive Compact conform to the

Machinery Directive 2006/42/EC

Tested and certied in accordance with applicable standards (see declaration of conformity

in chap. 2.8).

When installed in machines it is prohibited to start-up intended operation until it has

been ascertained that the completed machine fully complies with the provisions of

the Machinery Directive (2006/42/EC); compliance with IEC/EN60204 is mandatory.

Starting up intended operation is only permitted on compliance with the EMC Directive

2014/30/EU.

The devices full the demands of the harmonised product standard IEC/EN61800-5-1.

You will find information on the installation of your device in chapter "3 Mechanical

installation".

11

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

Pay attention to the topic of “Electrical equipment of machines” in IEC/EN60204-1:

2006 “Safety of machinery”. The safety requirements on electrical machines dened

there are intended to protect personnel and machinery or systems.

The emergency stop function (as per IEC/EN 60204) shuts down the supply of power

to a machine, which results in the drives coasting down in an uncontrolled manner. To

avert hazards, check whether it is appropriate:

− To keep individual drives in operation

− To initiate specic safety procedures

− To incorporate a Safe Torque Off function (Safe Torque Off: movement stop

by "switching off the electrical supply" - STO)

2.7 Relevant laws, standards and directives

applied

For information on the laws, Dateards and directives applied by Moog, refer to the

declaration of conformity.

NOTE:

Depending on the specic application for the devices, other laws, standards

and directives with provisions on "Safety" may apply. If necessary, contact

the machine or system manufacturer.

2.4.1 Repair

Only have repairs undertaken by authorised repair shops. Unauthorised opening and

incorrect intervention could lead to death, physical injury or material damage. The

warranty provided by Moog would thereby be rendered void.

2.5 Usage contrary to intended use

Our devices are:

yNot intended for installation in vehicles. Deployment of the device in non-

stationary equipment is classed as non-standard ambient conditions, and is

permissible only by special agreement.

yNot intended for installation in environments with harmful oils, acids, gases,

vapours, dusts, radiation etc.

yNot approved for usage in special applications (e.g. in potentially explosive

atmospheres or areas in which there is a risk of re).

yNot approved for usage outside a cabinet

yNot approved for the generation of high-frequency onboard

networks for which the device is not designed

2.6 Responsibility

Electronic devices are fundamentally not fail-safe. The installer and/or operator of a

complete machine or system is responsible for ensuring:

yThat the drive is rendered safe if the device fails

yThe safety of personnel and machinery

yThe complete machine is in correct working order

yFor the risk assessment on the complete machine or system according to

EN ISO 12100 (formerly EN ISO 14121) and EN ISO 13849-1

(formerly DIN EN 954-1)

12

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

2.8 Declaration of conformity

13

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

3 Mechanical installation

3.1 Notes for operation

CAUTION Damage to the device due to incorrect installation conditions!

The device may be destroyed

For this reason

• Moisture must not be allowed to enter the device

• There must not be any aggressive or conductive substances in the ambient air

• Foreign bodies such as drilling chips, screws, washers etc. must not be allowed to enter

the device

• The ventilation openings must not covered

Note the following points:

yCooling air must be able to ow through the device without restriction.

yFor mounting in switch cabinets with convection (= heat loss is discharged to the outside via the

cabinet walls), always t an internal air circulation fan.

yThe backing plate must be well-earthed.

yThe device is designed only for vertical installation in switch cabinets. The switch cabinet must

as a minimum provide IP4x protection.

yTo attain the best result for EMC-compatible installation you should use a chromated or

galvanized backing plate. If backing plates are varnished, remove the coating from the contact

area! The devices themselves have an aluminium back panel.

yMaximum pollution degree 2

NOTE

According to ENISO13849-2 the switch cabinet must have IP54 protection

or higher on using the STO (Safe Torque OFF) safety function.

Further information on environmental conditions can be found in the appendix.

3.2 Wall mounting

Step Action Comment

1.

Mark out the position of the tapped holes on the

backing plate.

Cut a thread for each xing screw in the backing plate.

Dimensional drawings/hole spacing see

Figure 3.1, Figure 3.2

The thread surface area will provide you

with good, full-area contact.

2. Mount the servo drive vertically on the backing

plate.

Observe the mounting clearances! The

contact area must be bare metal.

3. Mount the other components, suchas the mains lter,

mains choke etc., on the backing plate.

The cable between mains lter and servo

drive may be 300mm (11.81in) long.

4. Continue with the electrical installation in chapter 3.

Table 3.1 Mechanical installation

NOTE

Forced cooling by external air ow is necessary

for all sizes of the MSD Single-Axis Servo

Drive Compact. The air must be able to ow

unhindered through the device. If a temperature

cut-out occurs, the cooling conditions must be

improved.

Air ow: minimum 1.2 m/s (3.93 ft/s)

14

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

3. 2.1 Dimensions of the devices

Size C2 C3 C4 C5

MSD Single-Axis Servo

Drive Compact

G394-030

G394-020

G394-059

G394-035

G394-080

G394-065

G394-120

G394-160

Weight 1.0 kg (2.2 lb) 1.5 kg (3.3 lb) 2.8 kg (6.2 lb) 5.9 kg (13 lb)

B (width) 55 (2.17 ) 90 (3.54)

H (height)1) 210 (8.27) 290 (11.42) 291 (11.47 )

T (depth)1) 142 (5.59) 189 ( 7.4 4 ) 235.5 (9.27)

A27.5 (1.0 8 ) 20 (0.79)

A1 - - 40 (1.57) 50 (1.97 )

C225 (8.86) 305 (12.01) 313 (12.32)

C1 5 (0.20) 6 (0.24)

DØ 4.8 (0.19)

H1 235 (9.25) 315 (12.40) 324 (12.76)

Screws 2 x M4 4 x M4

All dimensions in mm (in)

1) without terminals/connections

Table 3.2 MSD Single-Axis Servo Drive Compact dimensions - see Figure 3.1 and Figure 3.2

C

C

C1

A

B

C1

H1

H1

A

B

A1

T

H

D

D

C2 + C3 + C4

C4

C2 + C3

Figure 3.1 Dimensional drawing C2, C3, C4

15

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

NOTE

If MSD Single-Axis Servo Drive Compact devices are attached to other

product ranges, corresponding measures must be taken to prevent the

devices affecting each other thermally.

Size C2 C3 C4 C5

MSD Single-Axis Servo

Drive Compact

G394-030

G394-020

G394-059

G394-035

G394-080

G394-065

G394-120

G394-160

E Direct butt mounting

F 1) ≥100 (3.94) ≥150 (5.9 0)

G 1) ≥235 (9.25) ≥280 (11.02)

Drawing:

Dimensions in mm (in) E

G

F

F

1) The bend radius of the connecting cables must be taken into account

Table 3.3 MSD Single-Axis Servo Drive Compact mounting clearances

A1A

DT

C

C1

H1

H2

B

H

Figure 3.2 Dimensional drawing C5

3.2.2 Mounting clearances

The minimum distances specied in the table apply for devices of the same power.

When butt mounting devices with different drive power you should arrange the devices

according to their power (e.g., viewed from the left, C5-C4-C3-C2). This arrangement

will minimise the thermal interaction.

16

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

17

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

4 Electrical installation

4.1 Notes for installation

DANGER Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Never wire or disconnect electrical connections while these are live! Always disconnect the power

before working on the device. Dangerously high voltages of ≥50V may still be present 10min.

after the power is cut (capacitor charge). So check that electrical power is not present!

Work on the device must only be carried out after the DC link voltage has dropped below a

residual voltage of 50V (indicated by monitoring LED H1 and to be measured on terminals X1/L-

and L+).

A dangerous voltage may be present at the device, even if the device does not emit any visual

or audible signals/indications (e.g. with mains voltage applied to terminal X3 and missing control

supply +24 V on X2)!

The following general guidelines apply for the installation of Servo Drives:

yCompliance with the EMC product standard

− Commissioning (i.e. starting intended operation) is only permitted on compliance with the

EMC product standard IEC/EN61800-3. The installer/operator of a machine and/or system

must provide proof of compliance with the protection targets stipulated in the standard.

yCable type

− Use only shielded mains, motor and signal lines with double copper braiding with 60 to 70%

coverage.

yCable laying

− Route mains, motor and signal cables separated from one another. If possible, keep a

distance of at least 0.2 m (0.66 ft), otherwise use separators. They should not run in parallel.

If crossovers are unavoidable, they should wherever possible be configured perpendicular (at

a 90° angle).

− Always route the motor cable without interruptions and the shortest way out of the control

cabinet. When using a motor contactor for example, the component should be directly

mounted to the servo drive and the shielding of the motor cable should not be stripped back

too far.

− If possible signal lines should only enter from one side into the switch cabinet.

− Lines of the same electric circuit must be twisted.

− Avoid unnecessary cable lengths and loops.

yEarthing measures

− Earthing measures of relevance for the servo drive are described in section “4.6 Protective

earth conductor connection”.

yShielding measures

− Do not strip the cable shields back too far, and lay them with large area connections both on

the component and on the backing plate or on the PE rail (main earth) for the backing plate.

yExternal components

− Place larger loads near the supply.

− Contactors, relays, solenoid valves (switched inductances) must be wired with suppressors.

The wiring must be directly connected to the respective coil.

− Any switched inductance should be at least 0.2 m (0.66 ft) away from the process controlled

assemblies.

yAdditional information can be found in the corresponding connection description.

If you require further detailed information on installation you should consult the Moog Helpline

(see “Commissioning” on page 45).

18

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

Number Designation

D1, D2 7-segment display

H1 DC link voltage indicator LED (only size C2 to C4)

OP1 Installation space for option 1 (Communication)

T1, T2 Button

X1 Power connections (only size C2 to C4)

X2 Connection for control supply UV

X3 AC power connection

PE (bottom) Device protective earth conductor connection

X4 Control terminals

X5 Motor temperature monitoring

X6 Resolver connection

X7 Connection for high-resolution encoder

X8 Option 2 (Technology)

X9 Ethernet interface

X13 Connection for motor brake

Table 4.1 Key to layout MSD Single-Axis Servo Drive Compact C2 to C4

4.2 Layout

The following shows the layout with the corresponding positions of plugs and terminals.

For better orientation we have identified the designations of plugs and terminals with an

abbreviation.

H1

X1

X8

X7

X6

D1, D2

T1, T2

X9

X2

X5

X13

X3

X4

TS-Software

PE

TS-Hardware

OP1

Figure 4.1 Layout MSD Single-Axis Servo Drive Compact C2 to C4

19

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

Number Designation

D1, D2 7-segment display

OP1 Installation space for option 1 (Communication)

T1, T2 Button

PE (top) Motor PE connection

X1.a Motor connection (only size C5)

X1.b Measurement of DC link voltage (only size C5)

X1.c Connection for braking resistor (only size C5)

X2 Connection for control supply UV

X3 AC power connection

PE (bottom) Device protective earth conductor connection

X4 Control terminals

X5 Motor temperature monitoring

X6 Resolver connection

X7 Connection for high-resolution encoder

X8 Option 2 (Technology)

X9 Ethernet interface

X13 Connection for motor brake

S Receptacle for shield plate (see “Detail1: Motor cable C5” on page 23)

T. Software Software rating plate

T. Hardware Hardware rating plate

Table 4.2 Key to layout MSD Single-Axis Servo Drive Compact C5

PE

X1.c

X1.b

X1.a

S

X8

X7

X6

D1, D2

T1, T2

X9

X2

X5

X13

X3

X4

T. Software

T. Hardware

PE

OP1

Figure 4.2 Layout MSD Single-Axis Servo Drive Compact C5

20

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.:CA97555-001 Date:04/2018

moog

Number Designation Details

D1, D2 7-segment display Page 48

T1, T2 Button Page 48

X1 Connection for motor, braking resistor

and measurement of DC link voltage Page 38

X2 Connection for control supply Page 27

X3 Connection for AC power supply Page 29

X4 Control terminals Page 31

X5 Connection for motor temperature monitoring1) Page 37

X6 Connection for resolver 1) Page 35

X7 Connection for high-resolution encoder 1) Page 36

Option 1 Communication Page 33

PE PE connection Page 25

X8 (Option 2) Technology Page 33

X9 Ethernet interface Page 33

X13 Connection for motor brake Page 32

1) Screen connections via separate shield plates Page 23

Connection for housing PE conductor Page 25

1) NOTE: The temperature sensor for the motor winding can be connected either via the encoder cables (X6 or X7) or to terminal X5.

Table 4.3 Key to connection diagram C2 to C4

4.3 Connection diagram C2 to C4

RB

L+

L-

U

V

W

X1

Ethernet

ISD00

ISD01

ISD02

OSD02

ENPO (STO)

Motor

3

ISDSH (STO)

ISA00+

ISA00-

ISA01+

ISA01-

E/A-GND

+24 V (UH)

3

4

5

6

10

15

16

17

9

23

24

22

RSH

STO

12

11

1

2,14

13

E/A-GND

Digital2

6

n

n

ISD03

ISD04

ISD05

18

19

20

ISD0621

OSD01

8

Digital1

OSD00

7

Digital0

GND

GND

V+

OSD03 2

3

4

1

5

9

10

9

OSD04

54321

10 9876

15 14 13 12 11

DGND

DGND

43 21

9876

~

1+

1-

1+

1-

+/1

-/2

(-)(+)

D1, D2

T1, T2

L1

K1

L2

L3

FN

L1

L2

L3

PE

PE

X3

X2

X9

X4

X8

X7

X6

X5

X13

-

+

+

–

1)

1)

Relay

Control

Service

interface

Analog set point 1

Analog set point 2

+24 V DC against

Diagnosis

DC-link

Mains 3-phase

Front

Option 1

Brake (+)

+24 V DC supply for

brake

Brake (-)

Resolver

Encoder

Top view

Bottom view

Braking

resistor

+24 V DC supply for

control electronic (UV)

Option 2

Relay

Communication

field buses

Danger!

Danger!

Figure 4.3 Connection diagram C2 to C4

This manual suits for next models

3

Table of contents

Other Moog Servo Drive manuals

Moog

Moog G393-004 User manual

Moog

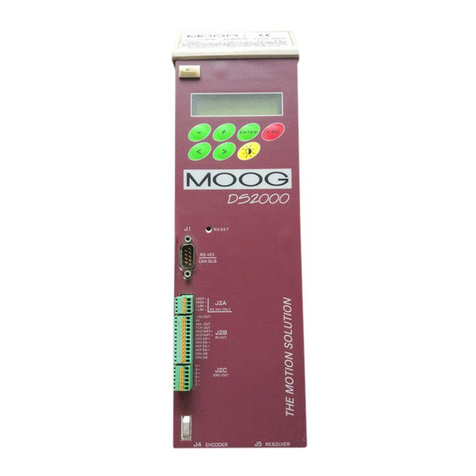

Moog DS2000 User manual

Moog

Moog G392-004 User manual

Moog

Moog MSD G393-004 User manual

Moog

Moog DS2020 Installation manual

Moog

Moog G394-030 User manual

Moog

Moog D633-A Series User manual

Moog

Moog G400 Series User manual

Moog

Moog DS2020 Mounting instructions

Moog

Moog MSD User manual

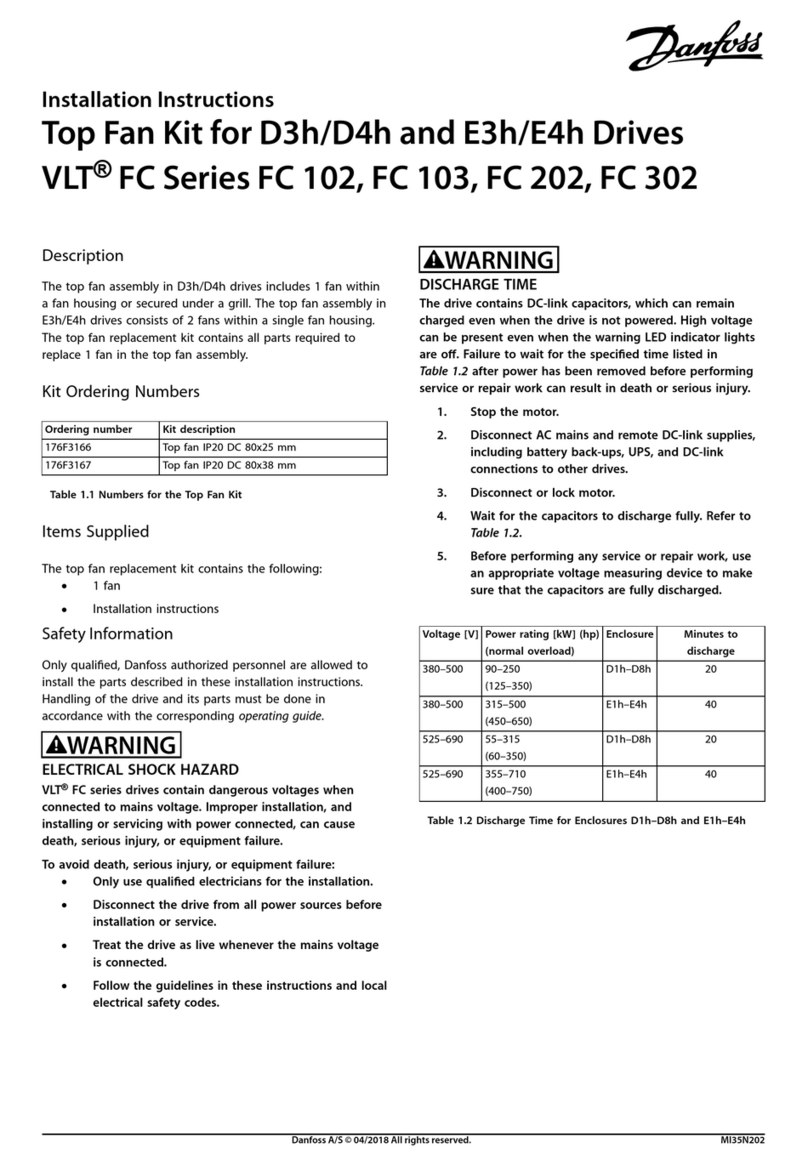

Popular Servo Drive manuals by other brands

Lenze

Lenze PROFINET 9400 Communications manual

Danfoss

Danfoss 176F3166 installation instructions

Copley Controls

Copley Controls Xenus PLUS manual

Bosch

Bosch Rexroth IndraDrive Mi Project planning manual

Smitec

Smitec COSMOS 301 Series Installation, use and maintenance manual

Applied Motion Products

Applied Motion Products ST5-IP Quick setup guide